An adaptive rewinding device

A self-adaptive, driving device technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of affecting accuracy, increasing the difficulty of disassembly, and loss of parts, so as to improve rewinding efficiency and improve The effect of roll quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

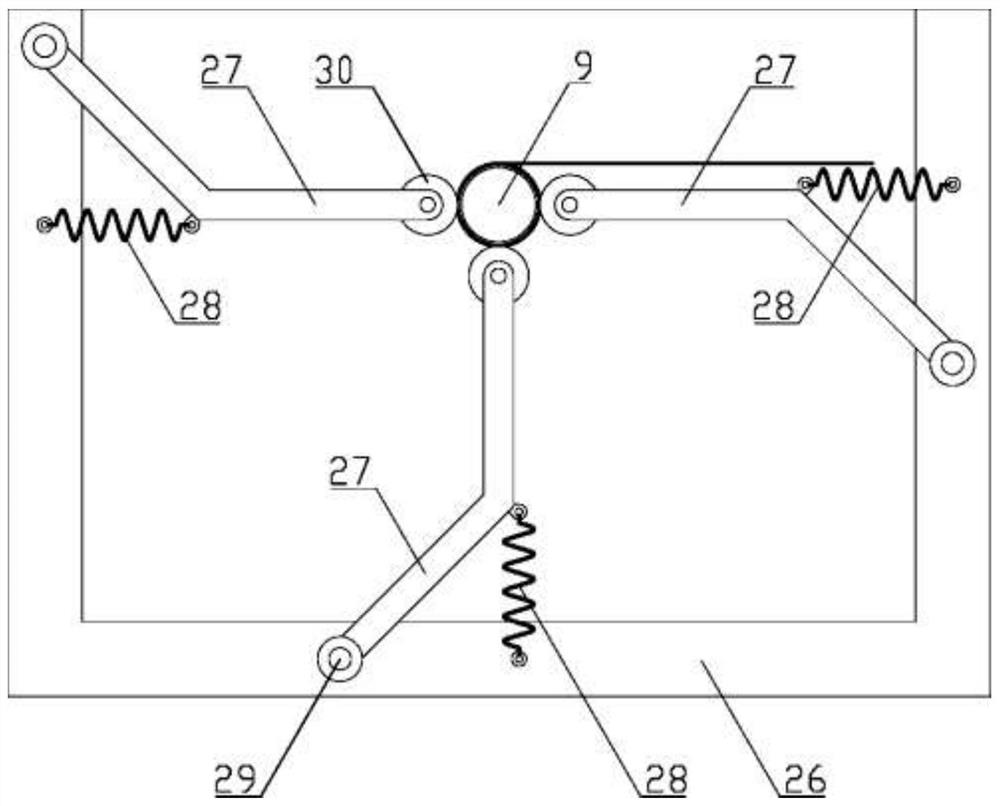

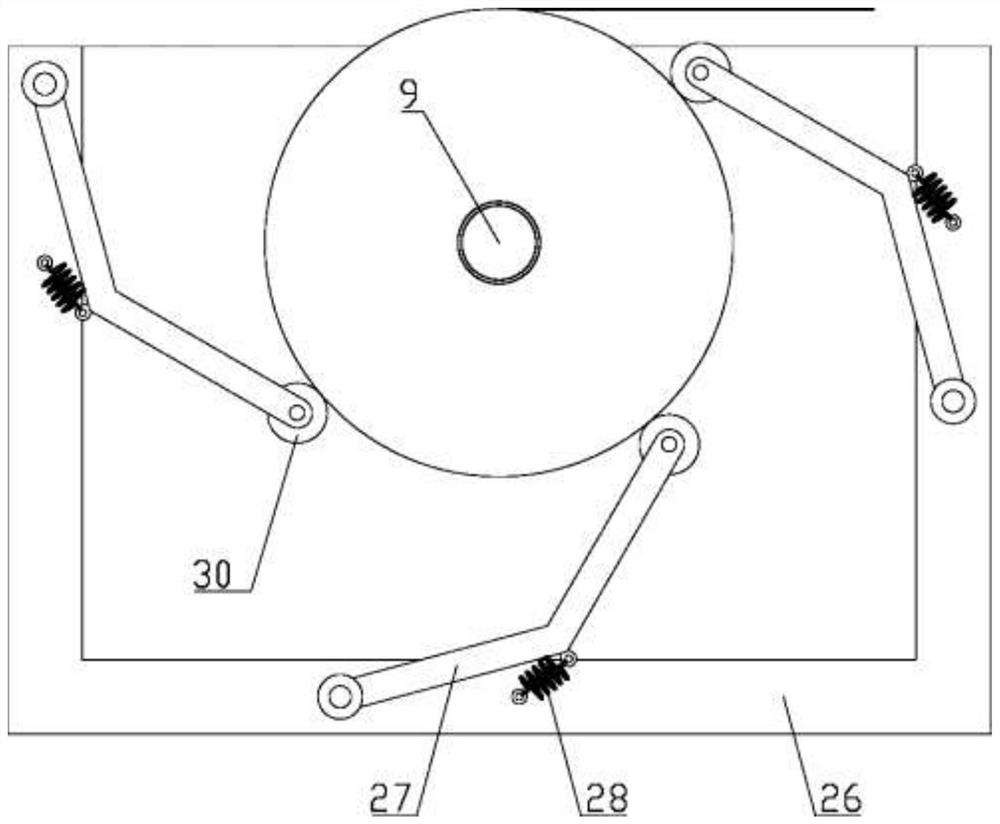

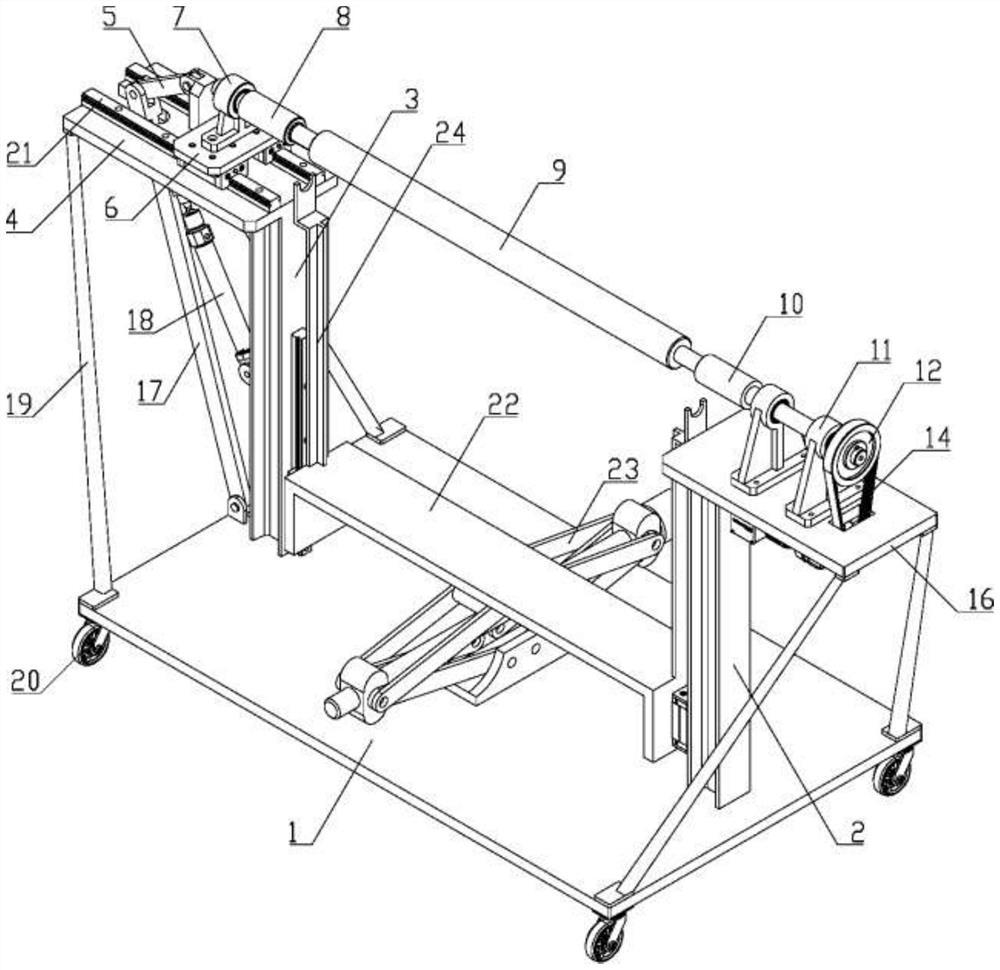

[0024]Such asFigure 1 to 4It is shown that the improvement of the present invention is only the improvement and optimization of the parts at the roll, and does not involve changes to the overall structure. For example, the positional relationship and structure of the rolls other than the rewinding roll 9 are not modified. Specifically, an adaptive rewinding device includes a main frame 1. The main frame 1 is also provided with a sub-frame 26 and a film roll 9 that is driven by the second driving device to rotate around its own axis. The sub-frame 26 is provided with There is at least one swing arm 27 that swings within a certain range and a reset device 28 that makes the swing arm 27 have a reset trend. The swing arm 27 is provided with a detector 29 for detecting its swing angle and a pressing wheel 30, and a pressing wheel for the swing arm 27 30 is driven by the film on the film roll 9 to rotate the swing arm 27 around its axis, and the detector 29 obtains the corresponding angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com