Nozzle with special water channel device

A water channel and special technology, applied in the field of spouts, can solve the problem of no temperature-adjusting device, etc., and achieve the effect of simple production process and reasonable water channel layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The nozzle provided with the special channel device of the present invention is suitable for various cavity molds.

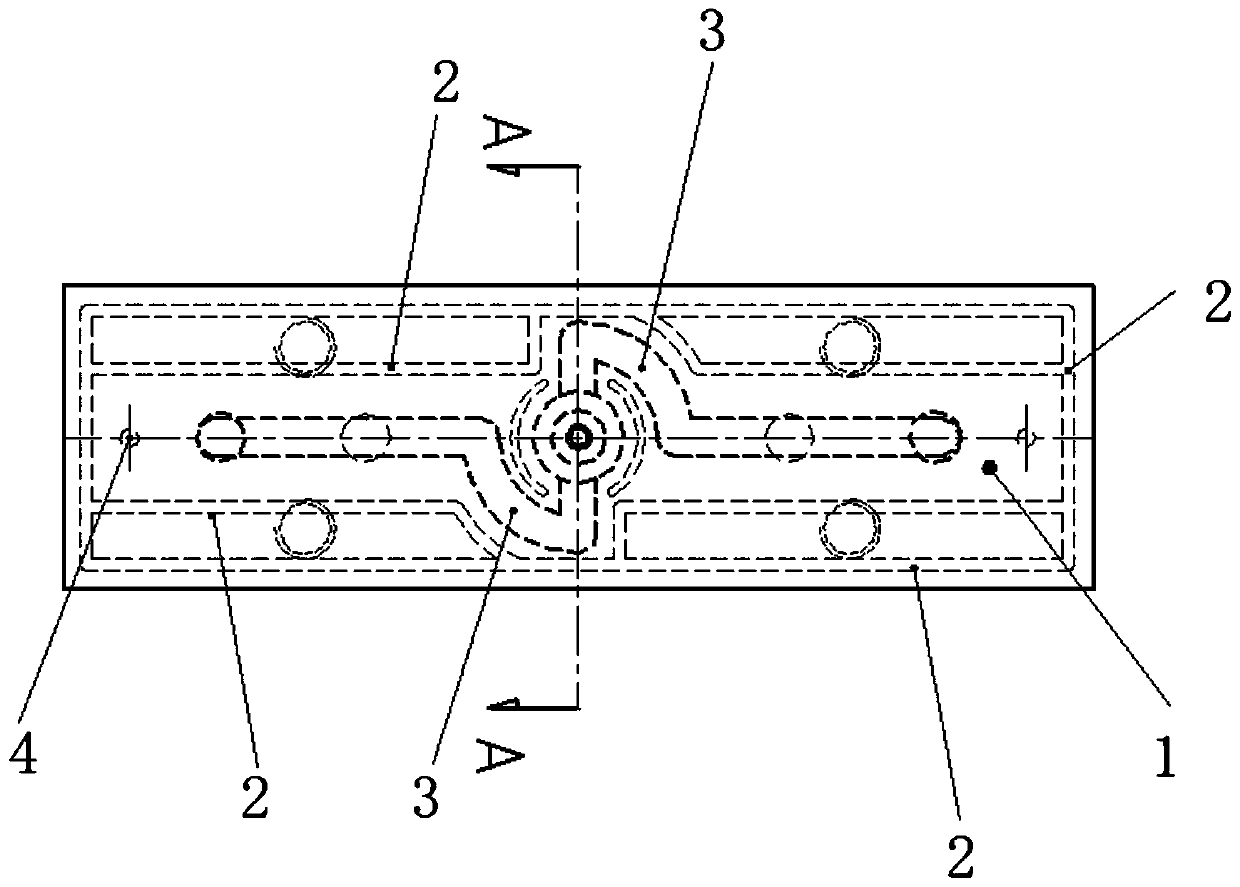

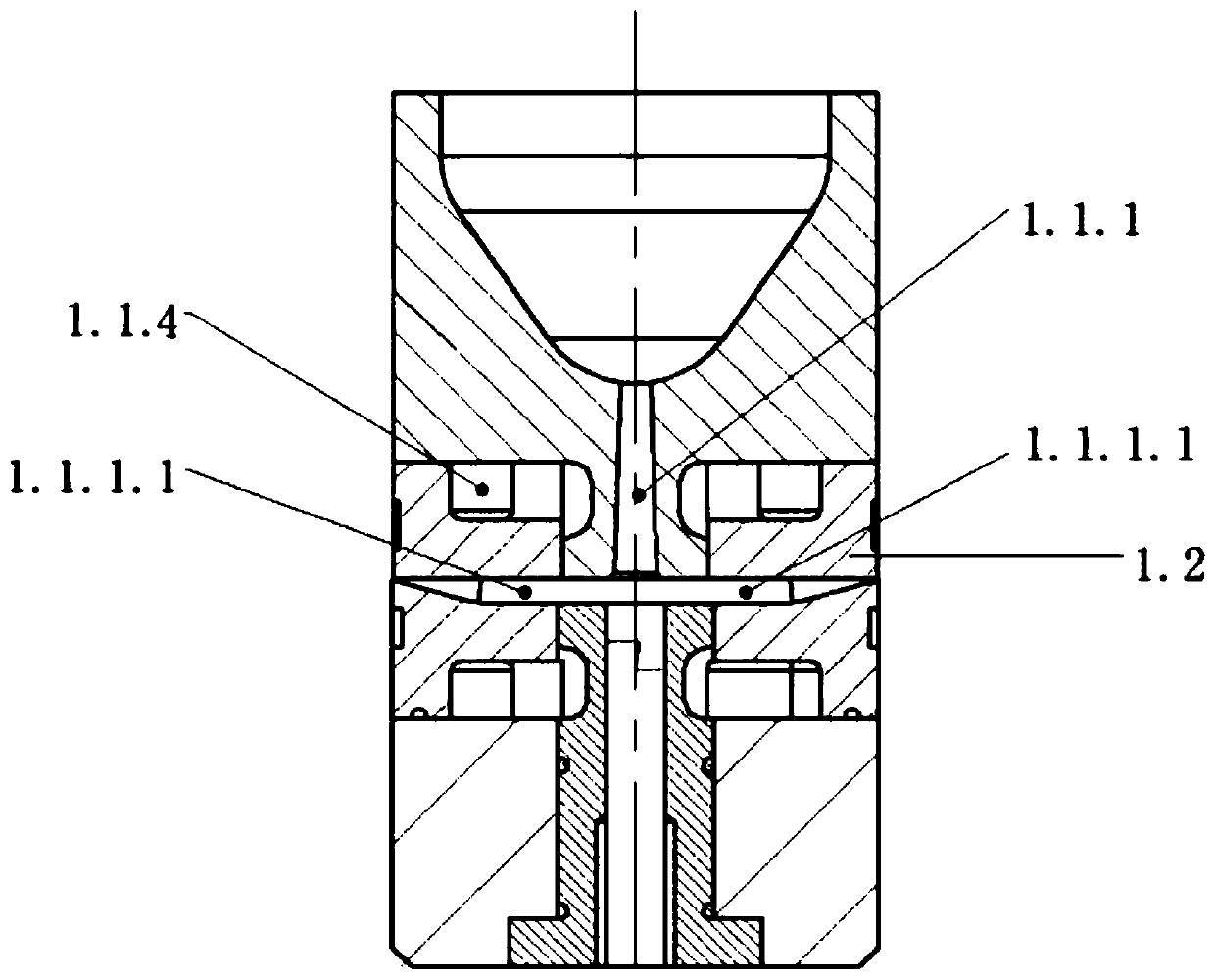

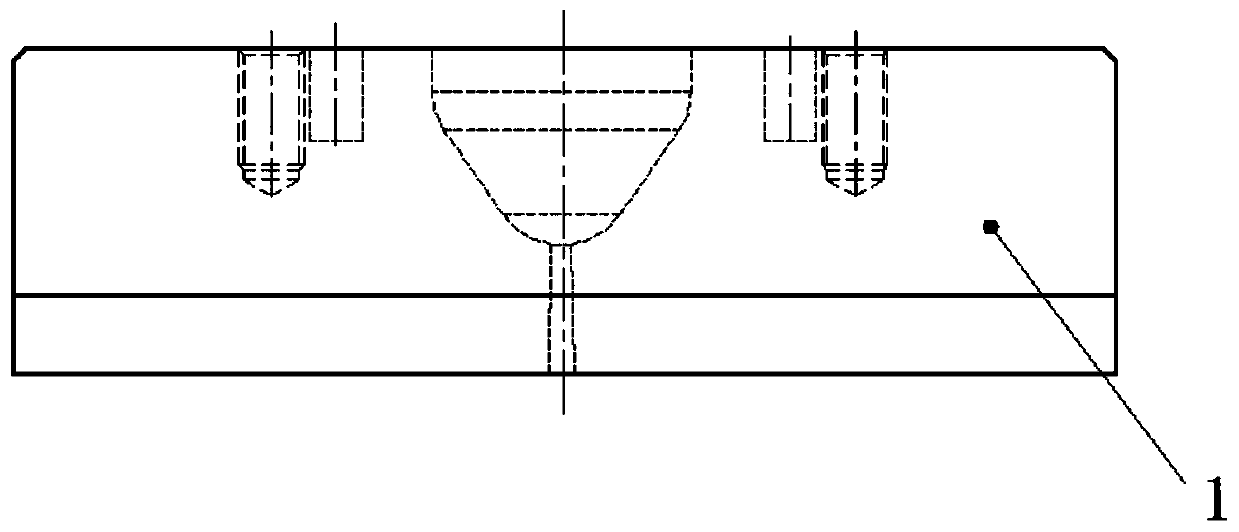

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , to describe in detail the preferred embodiment and other embodiments of the nozzle provided with the special waterway device of the present invention.

[0026] The present invention provides a nozzle provided with a special water channel device, which is characterized in that it includes a nozzle seat module 1.1 and a water channel module 1.2, and the nozzle seat module 1.1 or the water channel module 1.2 is sealed by solder melting and welding , the nozzle seat module 1.1 is provided with a feed channel 1.1.1, a water inlet 1.1.2, a water outlet 1.1.3 and a part 1.1.4 of the water channel, and the water channel module 1.2 is provided with another part 1.2.1 of the water channel, A part 1.1.4 of the waterway in the nozzle se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com