Curved glass polishing fixture, polishing method and polishing device

A technology of curved glass and polishing fixtures, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of poor polishing quality, thin double-bridge glass, collapse generation efficiency, etc. The effect of local collapse, reduction of height difference, uniform force and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

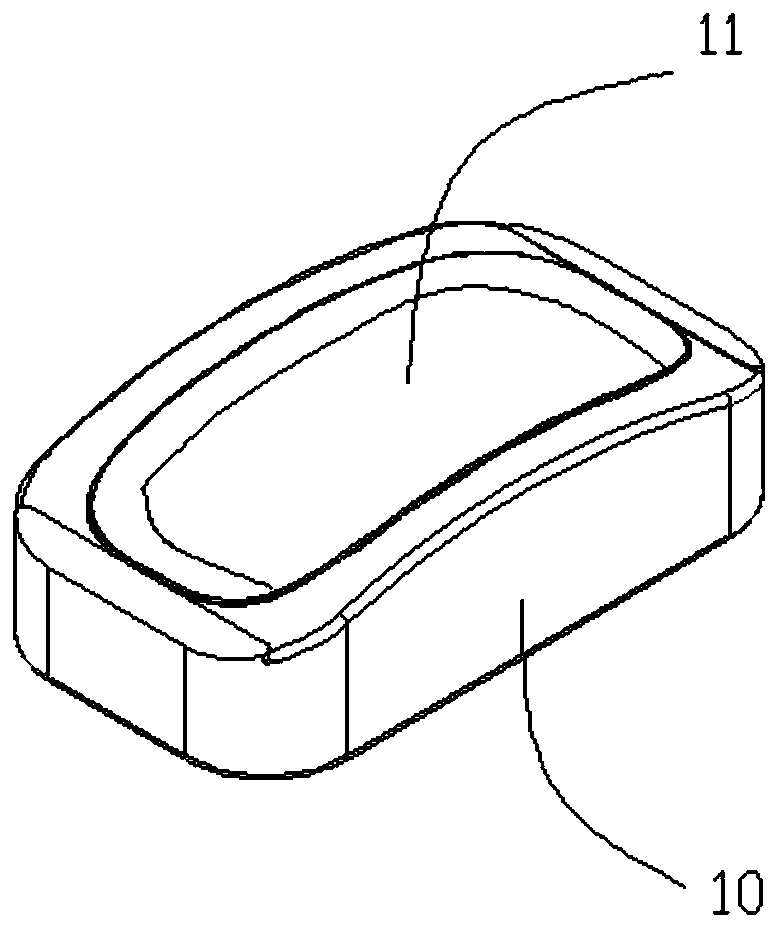

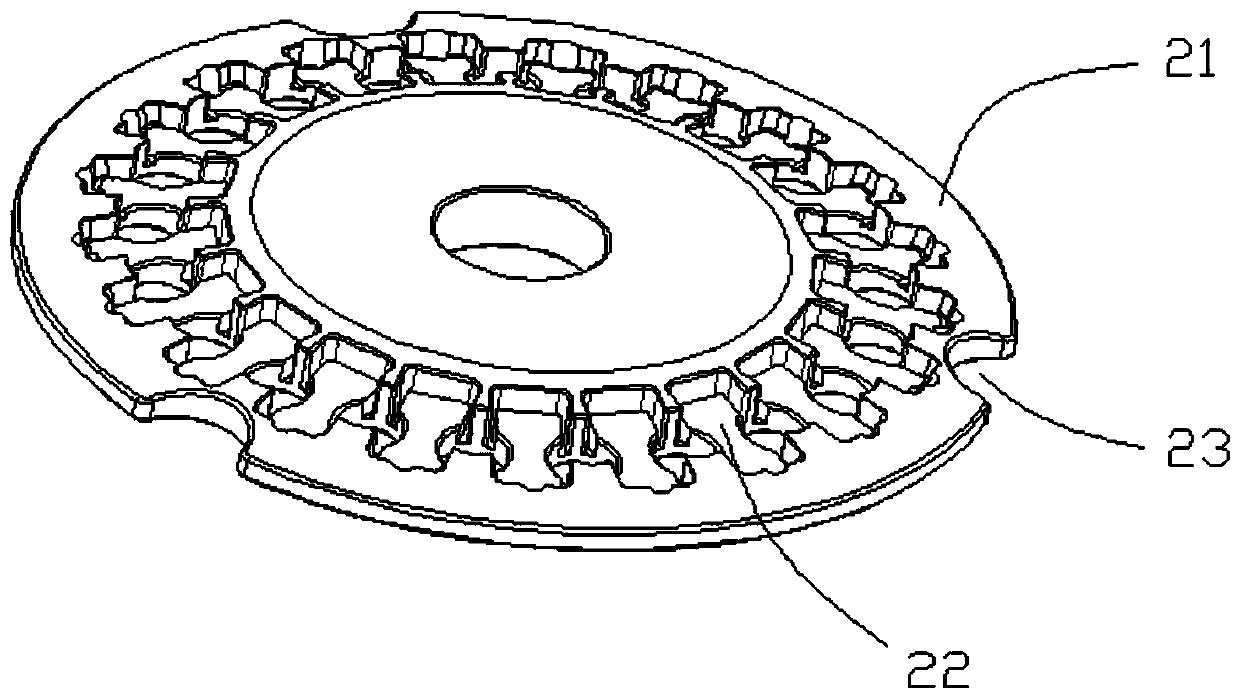

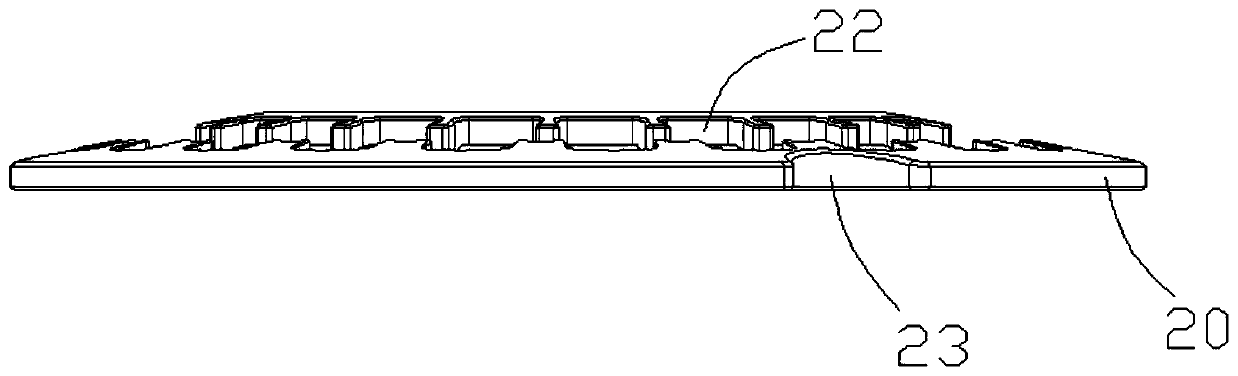

[0062] Such as Figure 1-5 As shown, this embodiment is a double-bridge glass polishing fixture, and its structure includes: a curved glass placement carrier 10 , a carrier plate 20 and an outer ring gear 30 . The double-bridge glass in this embodiment is bracelet glass, including the highest end surface and two special-shaped end surfaces R surfaces.

[0063] Wherein, the specific structure of the curved glass placement carrier 10 is as follows: figure 1 As shown, it includes a cavity 11 for placing the bracelet glass. The shape of the bottom support surface in the cavity 11 matches the shape of the curved glass to be processed, and the depth from the opening of the cavity to the bottom support surface is 0.1mm smaller than the thickness of the curved glass to be processed.

[0064] In this embodiment, the length and width of the curved glass placement carrier 10 are 100 mm and 70 mm respectively, and the depth from the opening of the cavity to the bottom support surface is...

Embodiment 2

[0072] This embodiment is a method for polishing curved glass. The polishing jig provided in Embodiment 1 is used to polish the ring glass. The specific steps include:

[0073] Step a): Install the brush plate on the flat grinder, and adjust the ratio of 3D polishing liquid;

[0074] Among them, the brush disc is made of 73-degree polished leather and white or gray nylon filament in a ratio of 1:1, 2:1 or 1:2; the 3D polishing liquid is a mixture of cerium oxide with a particle size of 0.3-1.5 microns , the concentration is 1.15g / ml;

[0075] Step b): Install the sintered and molded wristband glass with its front facing up in the curved glass placement carrier. A layer of black cushion with adhesive backing is attached to the curved glass placement carrier, and the black cushion is fixed on the bottom support surface;

[0076] Step c): Install the curved glass carrier in the groove of the bearing plate, fix the bearing plate and the outer ring gear, install the outer ring gea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com