Die casting technology of notebook computer shell

A notebook computer and die-casting technology, which is applied in the field of electronic product production, can solve the problems of not meeting the requirements of light and thin electronic products, rising production costs, and high die-casting defect rate, so as to prevent the mold core from losing temperature too quickly and save costs , good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

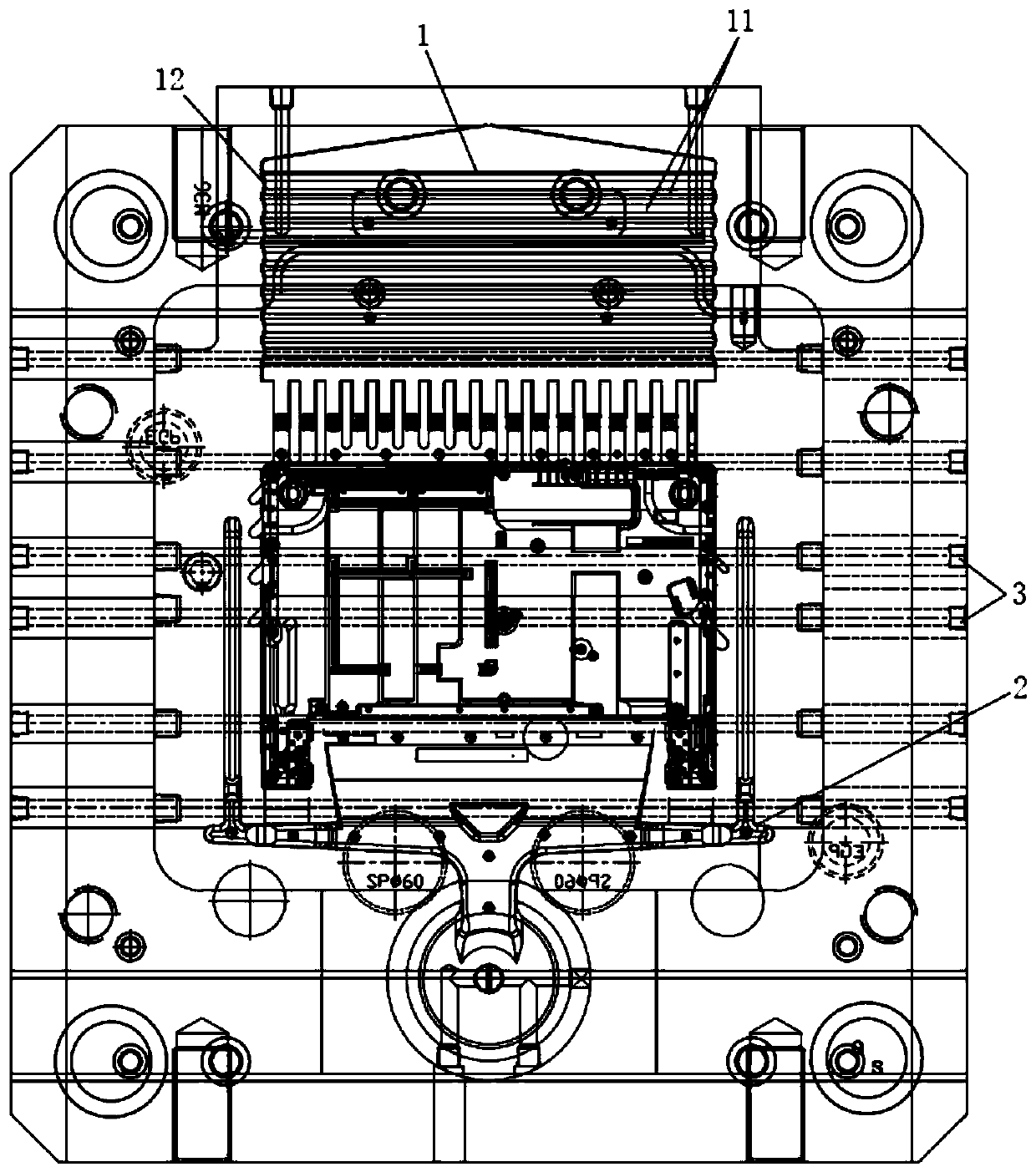

Image

Examples

Embodiment 1

[0036] A die-casting process for a notebook computer shell, using magnesium alloy as a raw material, and preparing the notebook computer shell with a die-casting machine, it includes the following steps:

[0037] Step 1, material dissolution: put the magnesium alloy raw material into the dissolution chamber of the die-casting machine for dissolution; in this embodiment, the temperature of the dissolution chamber is set to 690°C;

[0038] Step 2, molten alloy injection: the dissolved material is injected into the mold controlled by the mold temperature machine through the injection pipe at the injection speed of 3.0-5.0m / s and the casting pressure; in this embodiment, the molten alloy injection The soup feeding time is set to 0.4s; in this embodiment, the temperature of the injection tube used for molten alloy injection is set to 700°C; in this embodiment, the preheating temperature of the mold is set to 200°C;

[0039] Step 3, cooling: cooling the material in the mold; in this...

Embodiment 2

[0047] A die-casting process for a notebook computer shell, using magnesium alloy as a raw material, and preparing the notebook computer shell with a die-casting machine, it includes the following steps:

[0048] Step 1, material dissolution: put the magnesium alloy raw material into the dissolution chamber of the die-casting machine for dissolution; in this embodiment, the temperature of the dissolution chamber is set to 680°C;

[0049] Step 2, molten alloy injection: the dissolved material is injected into the mold controlled by the mold temperature machine through the injection pipe at the injection speed of 3.0-5.0m / s and the casting pressure; in this embodiment, the molten alloy injection The soup feeding time is set to 0.3s; in this embodiment, the temperature of the injection tube used for molten alloy injection is set to 690°C; in this embodiment, the preheating temperature of the mold is set to 180°C;

[0050] Step 3, cooling: cooling the material in the mold; in this...

Embodiment 3

[0058] A die-casting process for a notebook computer shell, using magnesium alloy as a raw material, and preparing the notebook computer shell with a die-casting machine, it includes the following steps:

[0059] Step 1, material dissolution: put the magnesium alloy raw material into the dissolution chamber of the die-casting machine for dissolution; in this embodiment, the temperature of the dissolution chamber is set to 700°C;

[0060] Step 2, molten alloy injection: the dissolved material is injected into the mold controlled by the mold temperature machine through the injection pipe at the injection speed of 3.0-5.0m / s and the casting pressure; in this embodiment, the molten alloy injection The soup feeding time is set to 0.5s; in this embodiment, the temperature of the injection tube used for molten alloy injection is set to 710°C; in this embodiment, the preheating temperature of the mold is set to 220°C;

[0061] Step 3, cooling: cooling the material in the mold; in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com