Multi-layer composite copper plate used for slab continuous casting machine crystallizer wide surface and preparing method thereof

A slab continuous casting machine and multi-layer compounding technology, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problem of uncontrollable heat transfer at the corners of the slab and reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

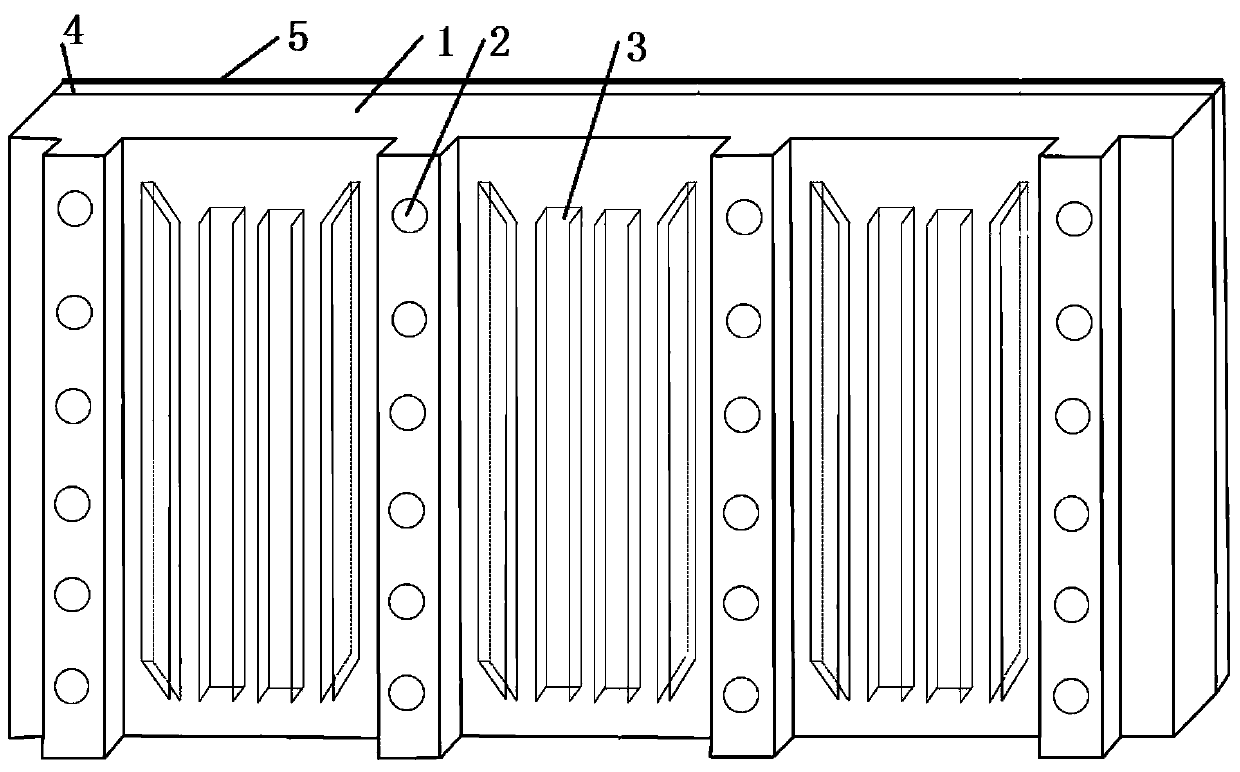

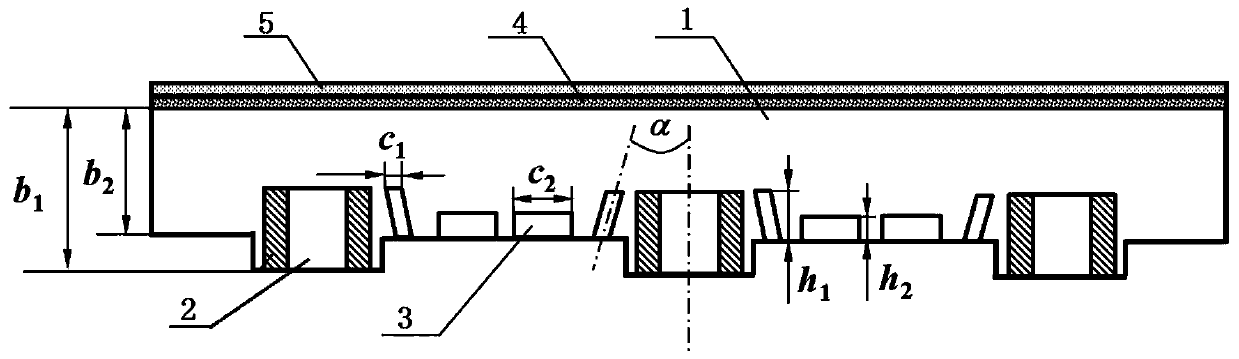

[0043] refer to figure 1 with figure 2, a multilayer composite copper plate used for the wide face of a slab continuous casting machine crystallizer, comprising at least one rectangular multilayer composite copper plate, is characterized in that: the multilayer composite copper plate is composed of a three-layer structure, from top to bottom The bottom is respectively the second coating layer 5, the first coating layer 4 and the multilayer composite copper plate body 1. Several rows of parallel protrusions are arranged on the lower surface of the multilayer composite copper plate body 1, and bolt holes are opened on the plurality of parallel rows of protrusions. 2. Bolts are connected in the bolt holes 2, and cooling water tanks 3 in the same direction as the protrusions are arranged in the grooves formed between two adjacent rows of parallel protrusions.

[0044] In actual use: By setting the multi-layer composite copper plate into a three-layer structure, the heat transfer...

Embodiment 2

[0046] Compared with Embodiment 1, the difference of this embodiment is that: four cooling water grooves 3 in the same direction as the protrusions are arranged in the grooves formed between two adjacent rows of parallel protrusions, and four cooling water grooves 3 The middle two are parallel to the raised water tanks, and the two adjacent to the middle two cooling water tanks 3 are inclined water tanks, the bottom of the inclined water tanks is inclined to the direction of the protrusion with the bolt hole 2, and the center of the inclined water tank and the bolt hole 2 The angle between the lines is α.

[0047] In actual use: four cooling water tanks 3 are provided, and the middle two of the four cooling water tanks 3 are water tanks parallel to the protrusions to increase the cooling effect and make the cooling effect better. The two adjacent to the middle two cooling water tanks 3 are The inclined water tank, the bottom of the inclined water tank is inclined to the direct...

Embodiment 3

[0049] Compared with Embodiment 2, the difference of this embodiment is that: the angle α between the inclined water tank and the center line of the bolt hole 2 is 12°-15°;

[0050] Preferably, the angle α between the inclined water tank and the centerline of the bolt hole 2 is 14°;

[0051] Preferably, the middle two are parallel to the width c of the raised water tank 2 18mm, depth h 2 is 6mm, and the width of the two inclined water grooves adjacent to the middle two cooling water grooves 3 is c 1 5mm, depth h 1 is 11mm.

[0052] In actual use: the angle α between the inclined water tank and the centerline of the bolt hole 2 is 12°~15°, and the angle α between the inclined water tank and the centerline of the bolt hole 2 is preferably 14°. By setting the angle α between the inclined water tank and the bolt hole 2 The included angle between the centerlines of holes 2 is used to further cool the copper plate around the bolts to ensure that the temperature of the entire mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com