Conjugated polymer photocatalyst and preparation method and application thereof

A technology of conjugated polymers and photocatalysts, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of low catalytic activity and achieve large ratio The effect of surface area, green environmental protection treatment technology, and high photocatalytic hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

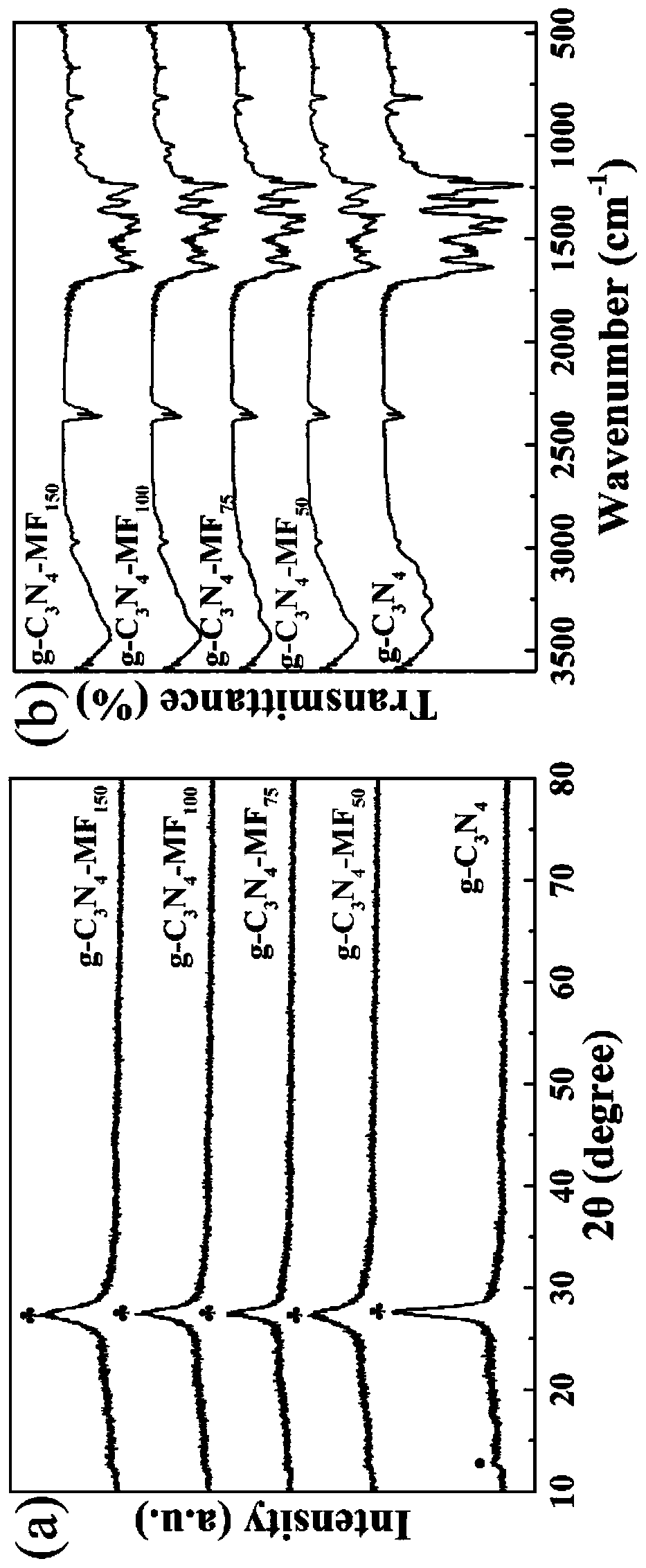

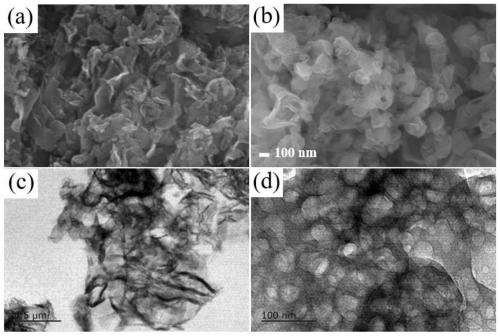

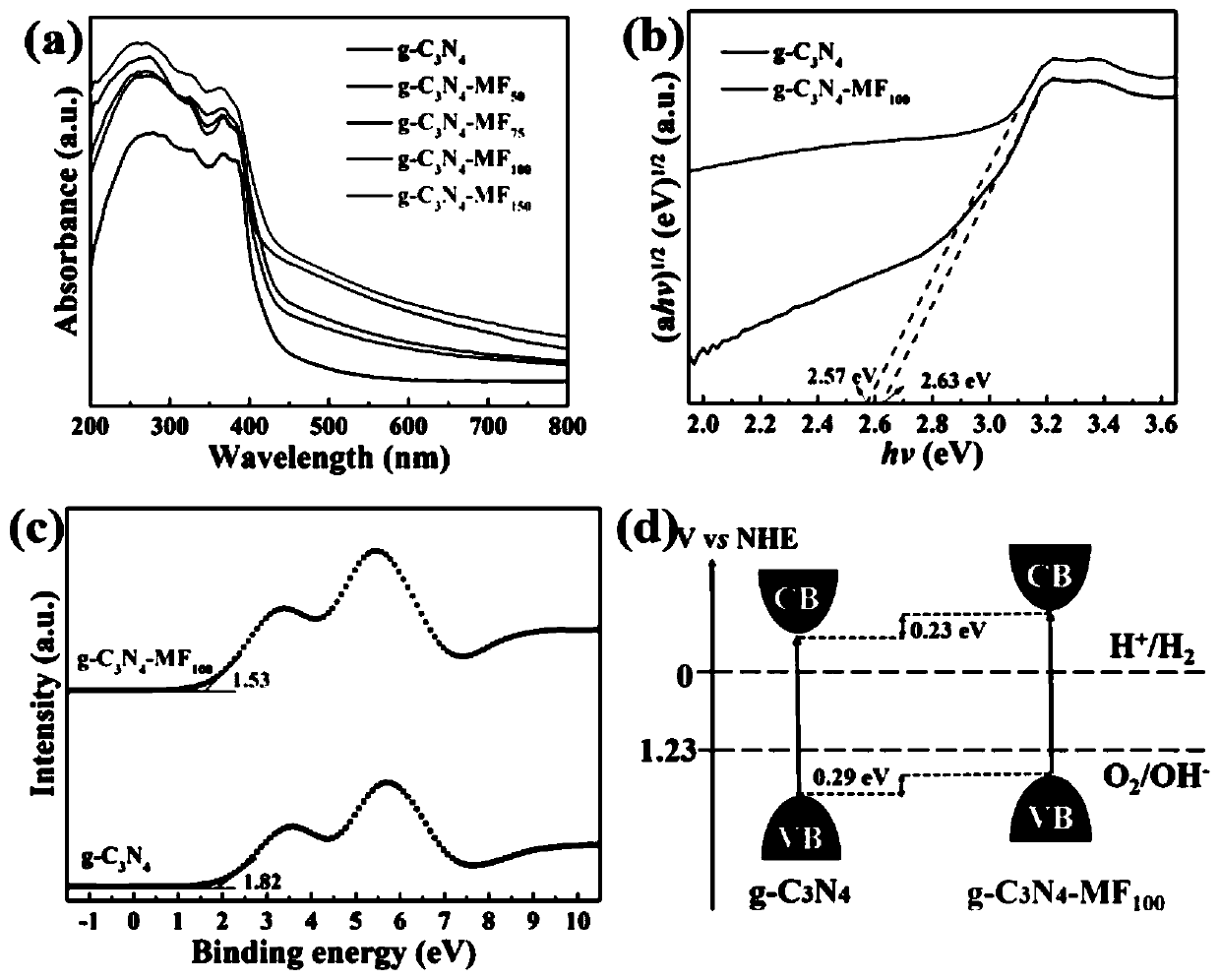

[0020] Porous g-C 3 N 4 -MF 25 Preparation of Conjugated Polymer Photocatalyst

[0021] First, 20g of urea was heated and melted at 140°C, then 25μL of melamine formaldehyde resin was added, stirred for 20min to form a uniform mixed solution, cooled to room temperature and ground, heated to 600°C at a heating rate of 5°C / min, and heated at 600°C Calcined under 3h.

Embodiment 2

[0023] Porous g-C 3 N 4 -MF 75 Preparation of Conjugated Polymer Photocatalyst

[0024] First, 20g of urea was heated and melted at 140°C, then 75μL of melamine formaldehyde resin was added, stirred for 20min to form a uniform mixed solution, cooled to room temperature and ground, heated to 600°C at a heating rate of 5°C / min, and heated at 600°C Calcined under 3h.

Embodiment 3

[0026] Porous g-C 3 N 4 -MF 100 Preparation of Conjugated Polymer Photocatalyst

[0027] First, 20g of urea was heated and melted at 140°C, then 100μL of melamine formaldehyde resin was added, stirred for 20min to form a uniform mixed solution, cooled to room temperature and then ground, heated to 600°C at a heating rate of 5°C / min, and heated at 600°C Calcined under 3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com