Method for treating hydrogen sulfide-containing gas

A processing method and technology for hydrogen sulfide, applied in chemical instruments and methods, gas fuels, separation methods, etc., can solve the problems of low hydrogen sulfide conversion rate and high decomposition energy consumption, and achieve low decomposition energy consumption and high hydrogen sulfide conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

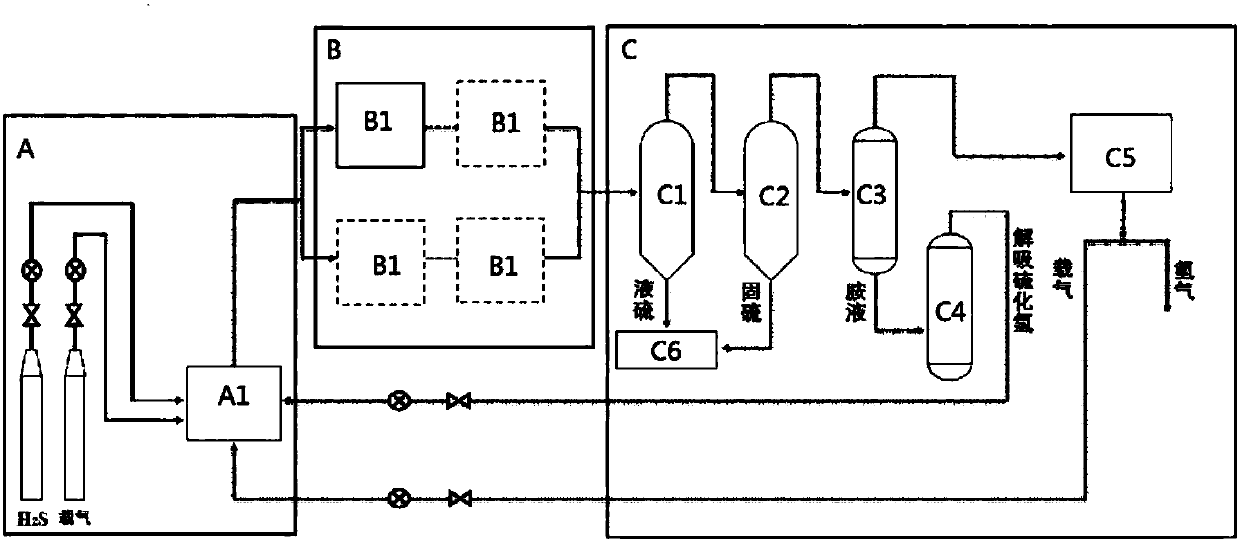

[0069] use figure 1 Shown flow chart carries out the method of the present invention, specifically:

[0070] (1) The feed gas containing hydrogen sulfide is introduced into the gas supply-gas distribution unit to mix with the carrier gas to obtain the reactant, the carrier gas is argon, and the amount of the carrier gas makes the amount of hydrogen sulfide in the reactant The content is 45% by volume;

[0071] (2) The reactant is introduced into the plasma reactor of the plasma reaction unit to carry out the hydrogen sulfide decomposition reaction under dielectric barrier discharge conditions. The dielectric barrier discharge conditions include: discharge voltage is 13.5kV, discharge frequency The discharge current is 500Hz, the discharge current is 1.73A, and the ratio of the discharge air gap to the thickness of the medium in the plasma reactor is 3:1, and the length of the discharge zone is 120cm; the conditions for the decomposition reaction include: the reaction temperat...

Embodiment 2

[0076] use figure 1 Shown flow chart carries out the method of the present invention, specifically:

[0077] (1) The feed gas containing hydrogen sulfide is introduced into the gas supply-gas distribution unit to mix with the carrier gas to obtain the reactant, the carrier gas is nitrogen, and the amount of the carrier gas is such that the content of hydrogen sulfide in the reactant is 30% by volume;

[0078] (2) The reactant is introduced into the plasma reactor of the plasma reaction unit to carry out the hydrogen sulfide decomposition reaction under dielectric barrier discharge conditions. The dielectric barrier discharge conditions include: discharge voltage is 17.2kV, discharge frequency is 2.3kHz, the discharge current is 2.0A, and the ratio of the discharge air gap in the plasma reactor to the thickness of the barrier medium is 0.5:1, and the length of the discharge zone is 200cm; the conditions for the decomposition reaction include: the reaction temperature is 142°C ...

Embodiment 3

[0083] use figure 1 Shown flow chart carries out the method of the present invention, specifically:

[0084] (1) The feed gas containing hydrogen sulfide is introduced into the gas supply-gas distribution unit to mix with the carrier gas to obtain the reactant, the carrier gas is helium, and the amount of the carrier gas makes the amount of hydrogen sulfide in the reactant The content is 15% by volume;

[0085] (2) The reactant is introduced into the plasma reactor of the plasma reaction unit to carry out the hydrogen sulfide decomposition reaction under dielectric barrier discharge conditions. The dielectric barrier discharge conditions include: discharge voltage is 15.7kV, discharge frequency The discharge current is 13500Hz, the discharge current is 1.1A, and the ratio of the discharge air gap in the plasma reactor to the thickness of the medium is 15:1, and the length of the discharge zone is 70cm; the conditions for the decomposition reaction include: the reaction temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com