Methanol gas water washing tank

A water washing tank and methanol technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of poor water washing effect, violent fluctuation, uneven gas-liquid contact, etc., achieve uniform distribution, stable flow, and improve water washing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

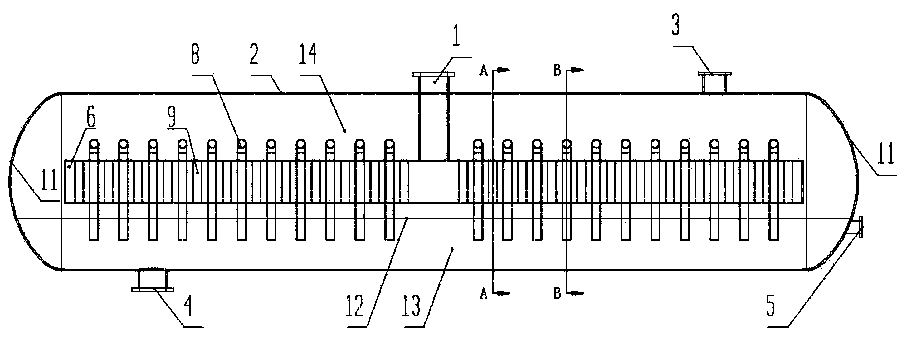

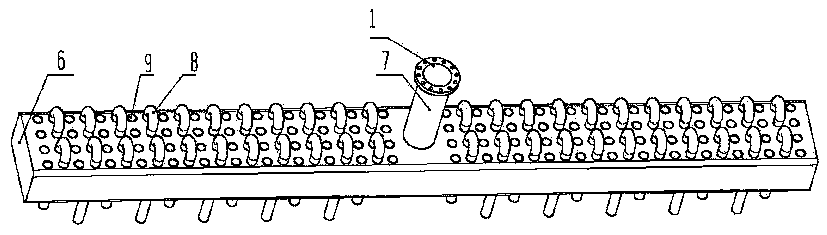

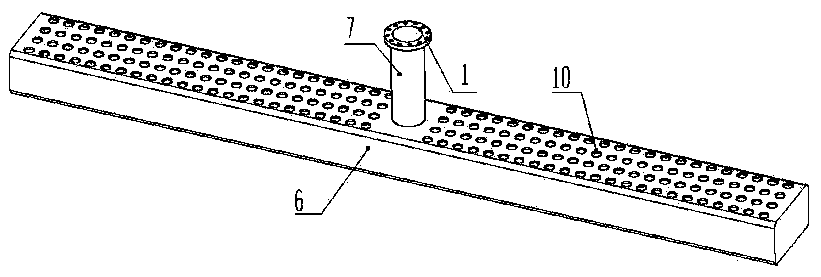

[0028] see Figure 1~5 , a methanol gas water washing tank of the present invention comprises a horizontal tank body 2, and the horizontal tank body 2 is composed of a horizontal cylindrical body and end caps 11 at both ends thereof. The top of the horizontal tank 2 is provided with a methanol gas inlet 1 and a purified gas outlet 3, the bottom of the horizontal tank 2 is provided with a purified water inlet 4, and the purified gas outlet 3 is provided with an overflow water outlet 5 on the adjacent head. 2 There is a buffer return chamber 6 in the middle of the inner cavity. The gas phase space 14 is above the water seal water level 12 in the horizontal tank body 2, and the water washing space 13 is below. The buffer return chamber 6 includes a bottom plate and a top plate, both of which are Horizontally arranged rectangular plate structure, the edge of the long side is connected with the side wall of the horizontal tank body 2, the length of the long side edge is equal to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com