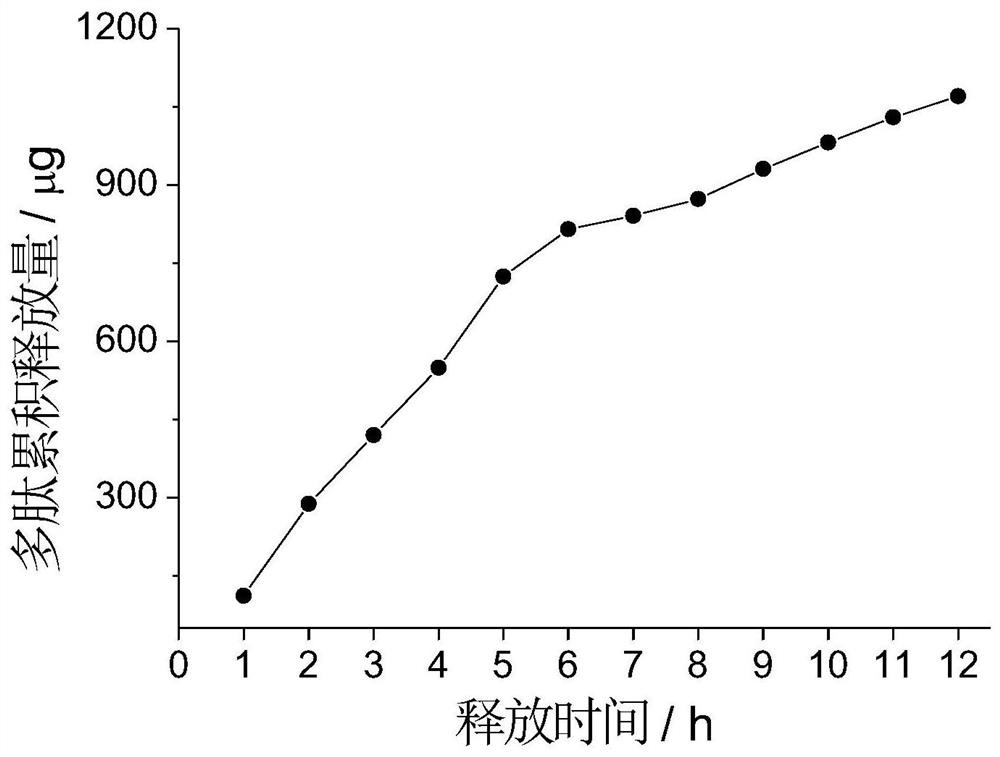

A kind of supramolecular polypeptide with self-assembled aggregate structure and preparation method thereof

A self-assembly and aggregation technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of single function, low effective utilization rate, and safety to be studied, and achieves mild process conditions and realizes Industrial production, excellent slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A supramolecular polypeptide with a self-assembled aggregate structure is formed by the self-assembly of an organic carboxylate-polypeptide two-component complex. Micron-scale self-assembly.

[0026] Further, the polypeptide is palmitoyl tetrapeptide-7, acetyl hexapeptide-8, palmitoyl tripeptide-1, acetyl tetrapeptide-5, palmitoyl pentapeptide-4, snake venom-like peptide, nonapeptide-1 , at least one of carnosine.

[0027] Further, the organic carboxylate is at least one of sodium laurate, sodium palmitate, sodium stearate, sodium oleate, sodium arachidonic acid, sodium behenate, sodium hyaluronate, and sodium alginate.

[0028] A kind of preparation method of the supramolecular polypeptide with self-assembled aggregate structure, its technology comprises the steps:

[0029] Step 1. Dissolve the polypeptide in a solvent with a pH value of 5-8, and the concentration of the polypeptide is 0.01-100 mg / mL;

[0030] Step 2, adding organic carboxylate to the solution forme...

Embodiment 2

[0034] A kind of preparation method of the supramolecular polypeptide with self-assembled aggregate structure, its technology comprises the steps:

[0035] Step 1. Add palmitoyl tetrapeptide-7 into a 100 mL round-bottomed flask equipped with a magnetic stirring bar, and then add sodium acetate buffer with a pH value of 5.0 to it to form a mixed solution. The palmitoyl tetrapeptide-7 is in The concentration in the mixture is 10 mg / mL;

[0036] Step 2. Put the round-bottomed flask with the mixed solution on a constant temperature water bath magnetic stirrer, the temperature of the water bath is 70°C, then add sodium laurate to it, stir at a rotational speed of 300r / min for 4h, and cool to 10°C Then, supramolecular polypeptides are obtained. The mixed solution after the reaction was centrifuged at 3000 r / min for 5 min, the supernatant was discarded, the obtained precipitate was washed three times with distilled water, and then freeze-dried into powder, and the obtained powder wa...

Embodiment 3

[0038] A kind of preparation method of the supramolecular polypeptide with self-assembled aggregate structure, its technology comprises the steps:

[0039] Step 1. Add acetyl hexapeptide-8 into a 100 mL round-bottomed flask equipped with a magnetic stirrer, and then add sodium acetate buffer with a pH value of 5.0 to it to form a mixed solution. The acetyl hexapeptide-8 is in The concentration in the mixture is 30mg / mL;

[0040] Step 2. Put the round-bottomed flask containing the mixed solution on a constant temperature water bath magnetic stirrer, the temperature of the water bath is 70°C, then add sodium palmitate to it, stir at a rotational speed of 500r / min for 6h, and cool to 10°C Then, supramolecular polypeptides are obtained. The reaction mixture was centrifuged at 5000 r / min for 10 min, the supernatant was discarded, the obtained precipitate was washed three times with distilled water, and then freeze-dried into powder, and the obtained powder was sealed and stored at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com