Centrifugal reagent disk

A reagent disc and centrifugal technology, applied in the field of centrifugal reagent discs, can solve the problems of high device cost, complicated device structure, difficult solid-liquid separation technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

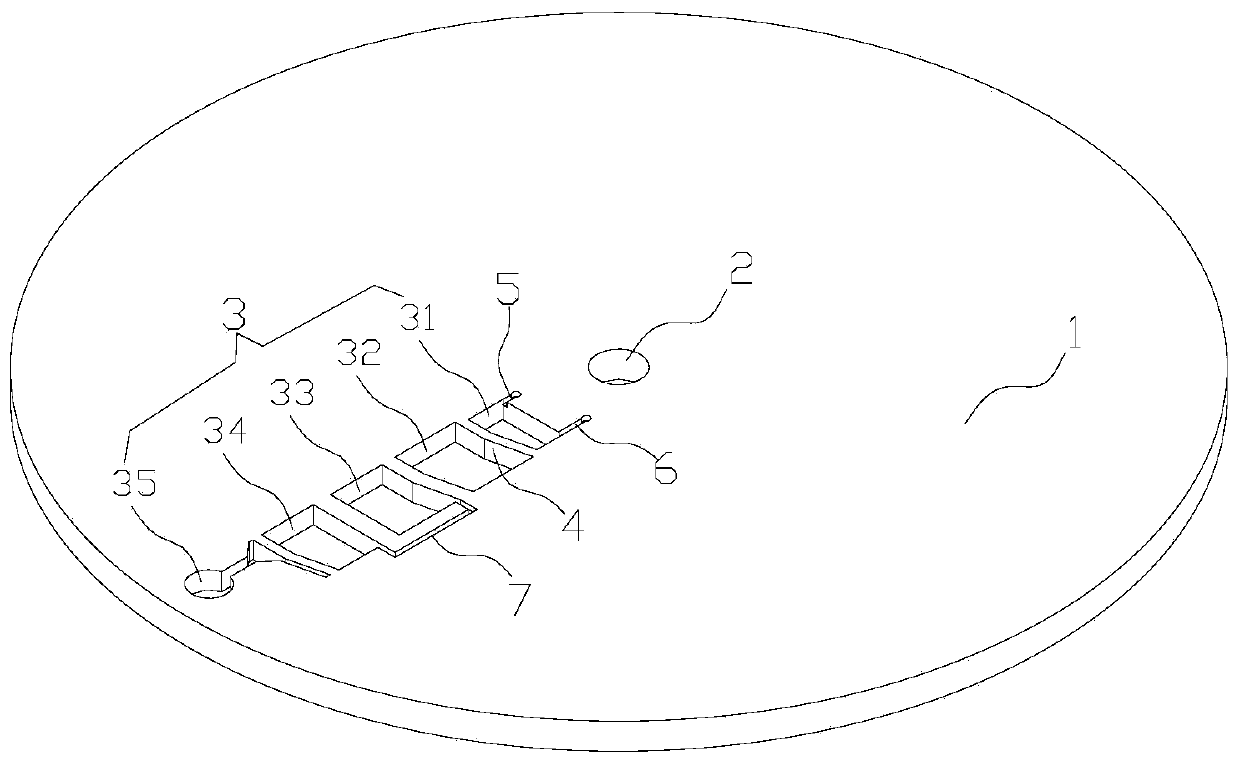

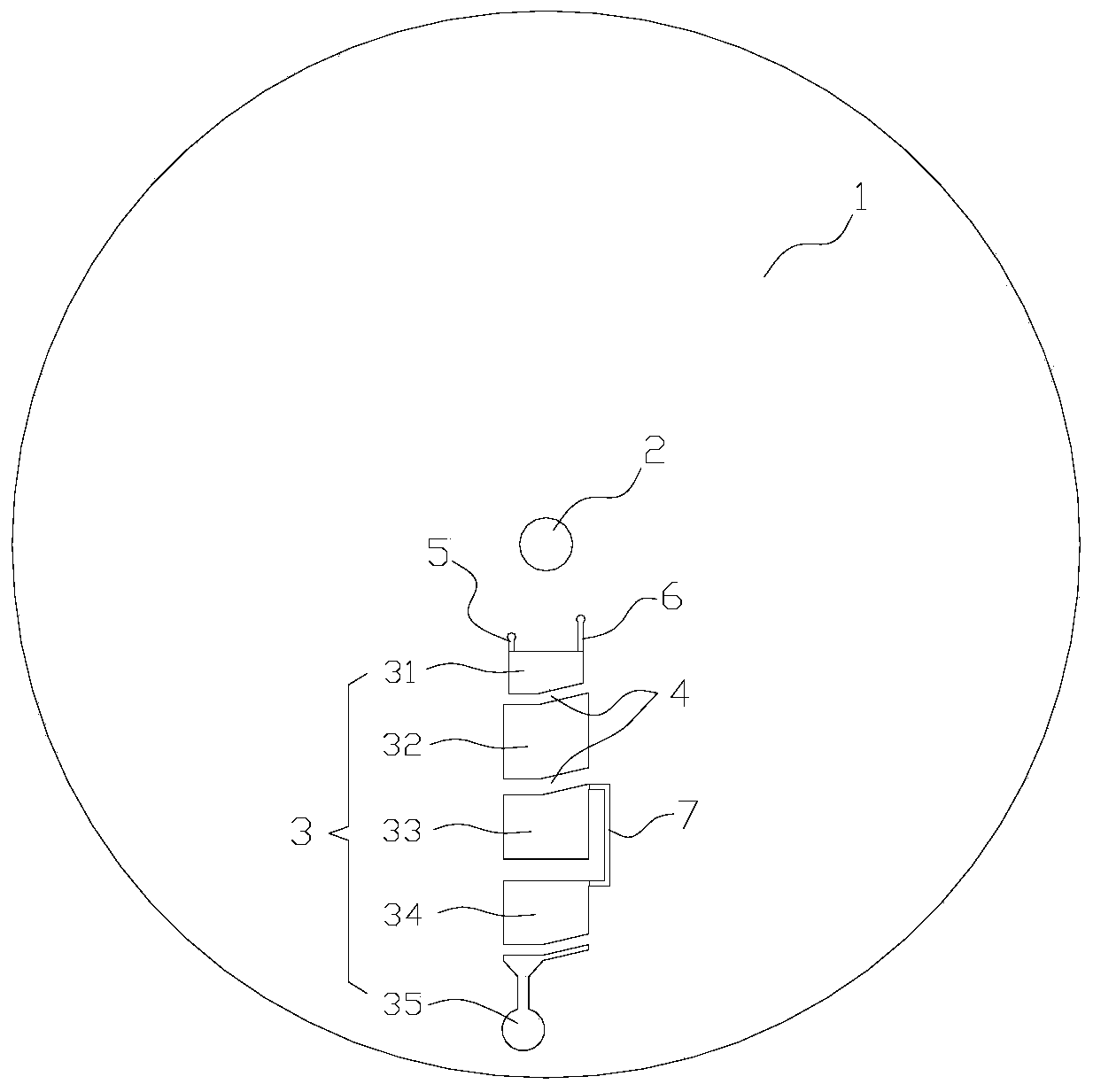

[0088] like Figure 1 to Figure 2As shown, it is a schematic structural diagram of a centrifugal reagent disc in the present invention. The centrifugal reagent disc includes a base plate 1, and the base plate 1 has a rotation center 2. In this embodiment, the base plate 1 is disc-shaped, and the center of the base plate 1 is provided with a Central hole, in this embodiment, the central hole is the rotation center 2 of the substrate, and the centrifugal reagent disc can be installed on the centrifugal device (not shown) through the central hole, and the substrate 1 is made of cycloolefin copolymer (COC / COP) The base material is obtained by injection molding.

[0089] The substrate 1 includes at least one set of test units (only one set of test units is shown in the diagram of this embodiment). The test unit includes at least two chambers 3 and a weir structure 4 arranged between adjacent chambers 3. Valves are arranged on the weir structure 4; The closest chamber 3 is a proxi...

Embodiment 2

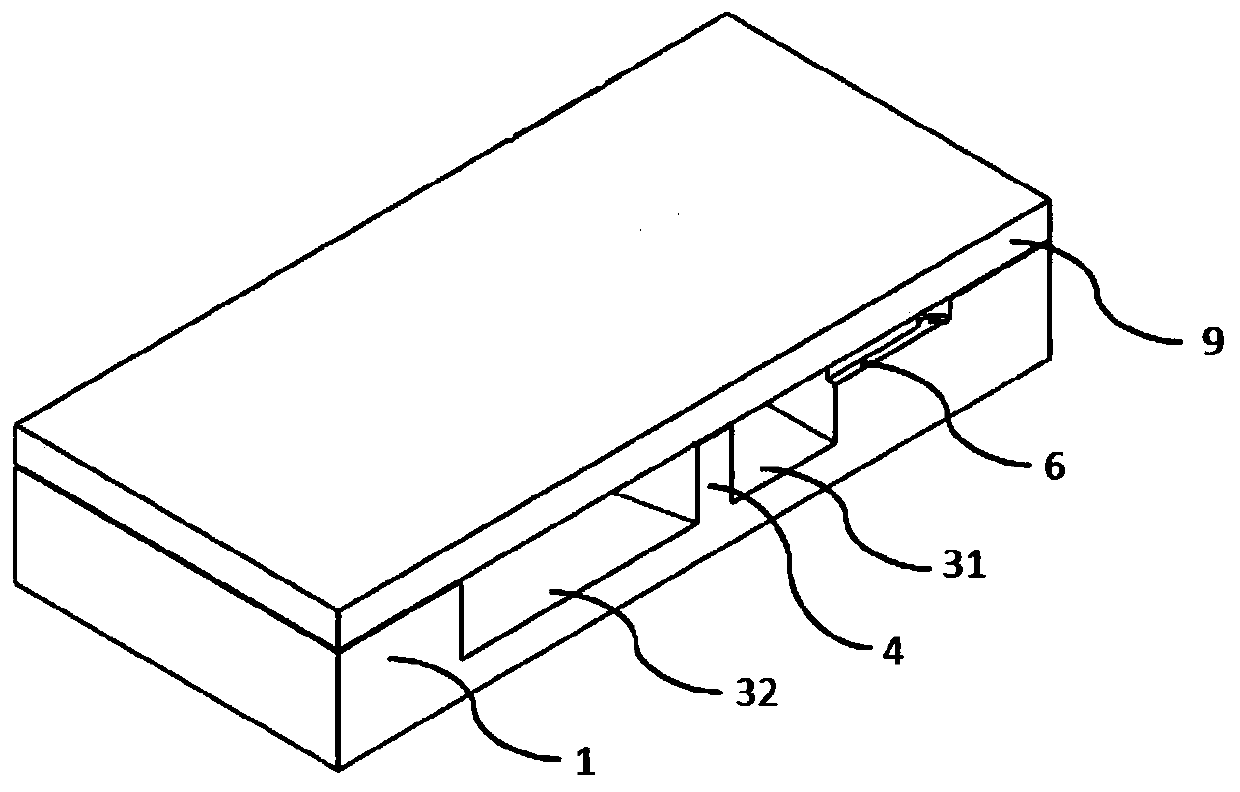

[0098] like Figure 8 to Figure 9 As shown, it is a schematic structural diagram of another centrifugal reagent disc in the present invention. This embodiment is a further improvement on the basis of Embodiment 1. As an improvement of this embodiment, this embodiment is different from Embodiment 1. The difference is that: the first pre-embedded chamber 32 is provided with an exhaust channel 6, and the position of the film 9 corresponding to the top of the exhaust channel 6 has a color mark for subsequent use; Store with lyophilized reagent pellets III.

[0099] When a test needs to be performed, use a sharp tool such as a syringe needle to pierce the film 9 with color marks at the top of the sampling channel 5 and the top of the exhaust channel 6, and then add liquid to the sample chamber 31 sample. By increasing the rotational speed of the substrate 1 fixed on the centrifugal device, the sample can enter the first pre-embedded chamber 31 to mix and react with the liquid rea...

Embodiment 3

[0101] like Figure 10 As shown, it is a schematic structural diagram of a centrifugal reagent disc in the present invention. This embodiment is a further improvement on the basis of Embodiment 1. As an improvement of this embodiment, the differences between this embodiment and Embodiment 1 The location is: the second pre-embedded chamber 33 is provided with an exhaust channel 6, and the position of the film corresponding to the top of the exhaust channel 6 has a color mark for subsequent use. The first pre-embedded chamber 32 and A bypass channel 7 is provided between the third pre-embedded chambers 34; freeze-dried reagent balls are stored in advance in the first pre-embedded chamber 32; liquid reagents are pre-stored in the second pre-embedded chamber 33; Freeze-dried reagent balls are pre-stored in the chamber 34. Second, liquid reagents are pre-stored in the detection chamber 35.

[0102] When a test needs to be performed, use a sharp tool such as a syringe needle to pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com