Novel fermentation tank and application thereof for fermented preparation of ethyl alcohol from immobilized yeast

A technology for immobilizing yeast and fermenters, which is applied to methods such as methods of immobilization on or in inorganic carriers, methods for immobilization on/in organic carriers, and methods for supporting/immobilizing microorganisms, can solve problems such as poor results, and achieve Improve the heat dissipation effect, reduce the material blockage, and the effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

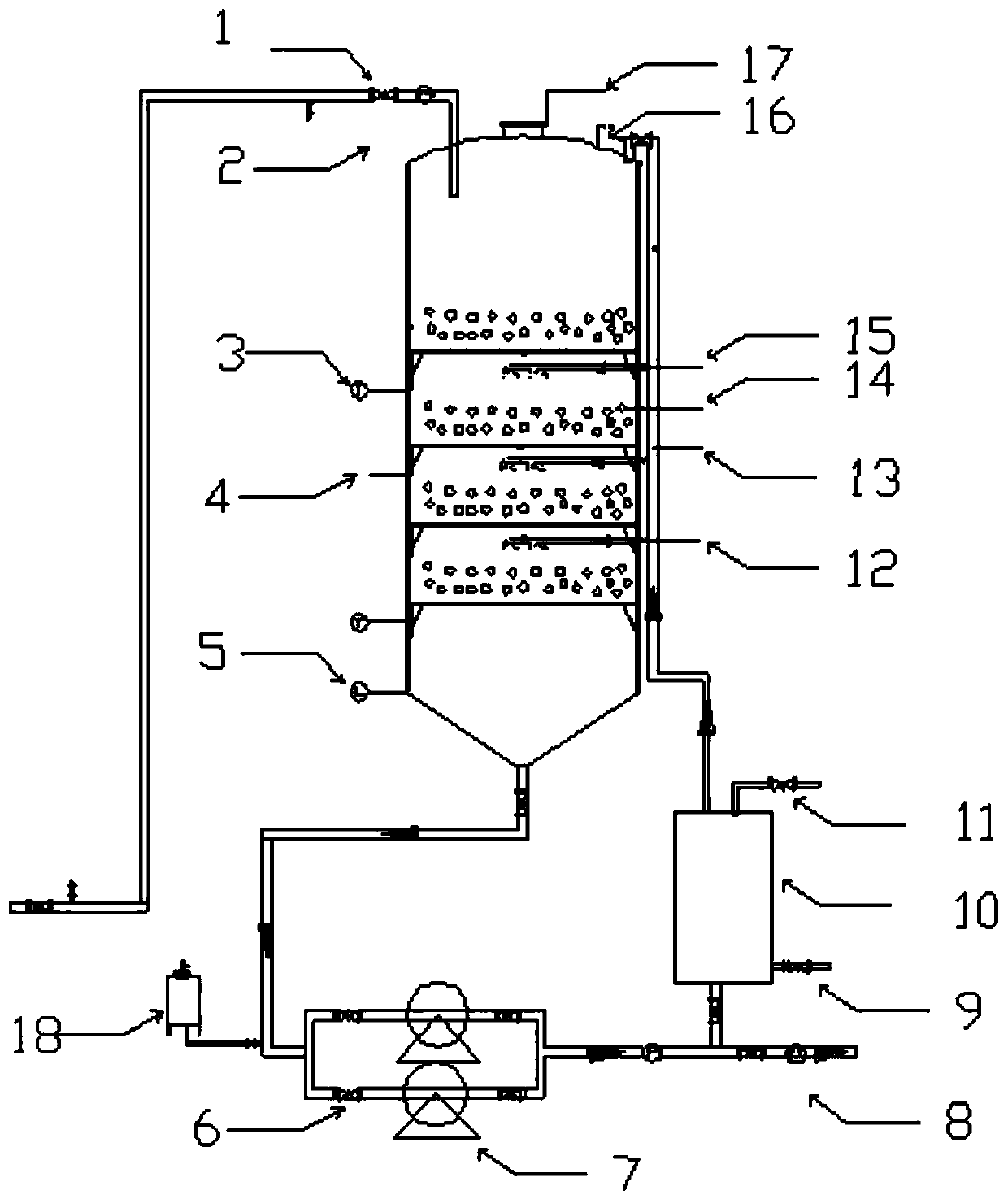

[0038] Example 1 Preparation of fuel ethanol by using molasses as fermentation raw material and adopting bamboo fiber immobilized yeast

[0039] First, put bamboo fiber (thickness 0.15cm) cut into diameter 15cm into polyethylene (density 0.94g / cm 3 ) made as figure 1 In the spherical grid with a diameter of 20cm shown, the immobilization carrier was prepared; then the immobilization medium was 2 The filling amount per L is placed in a 20-ton reactor with a height-to-diameter ratio of 3:1. Then the cultured bacterial classification is added in the fermenter that 4 layers of grating plates are housed (every layer of feed pipe in the tank (i.e. figure 1 The shown flush water flow tube) nozzle is located in the middle position, and the multi-directional nozzle is facing around), and the flow rate is 10m 3 The / h cycle is fixed at 36h. Until the bacterial cell adsorption concentration is 200 million / ml. Then drain to waste. Then add the molasses fermentation medium (total sug...

Embodiment 2

[0040] Example 2 Production of fuel ethanol using cassava liquefied mash medium as fermentation raw material and cotton fiber immobilized yeast

[0041] First, put the cotton fiber cut into a diameter of 18 cm into a spherical grid with a diameter of 25 cm made of polyethylene (density 0.92 g / cm 3 ), prepared as an immobilization medium; then the immobilization medium was 120cm 2 The filling amount per L is placed in a 20-ton reactor with a height-to-diameter ratio of 3:1. Then the cultured strains are added to the fermenter equipped with 3 layers of grid plates (the nozzle of each layer of feed pipe in the tank is located in the middle, and the multi-directional nozzle is facing all around), with a flow rate of 10m 3 The / h cycle is fixed at 30h. Until the bacterial cell adsorption concentration is 250 million / ml. Then prepare cassava liquefied mash: the ratio of solid to liquid is 1:2.5, add liquefaction enzyme (15U / g cassava dry weight) to liquefy at 85°C for 2 hours, an...

Embodiment 3

[0042] Example 3 Production of fuel ethanol using high-concentration cassava liquefied mash medium as fermentation raw material and immobilized yeast with cotton fiber

[0043] First, put the cotton fiber cut into a diameter of 8 cm into a spherical grid with a diameter of 12 cm made of polyvinyl fluoride (density 0.89 g / cm 3 ), prepared as an immobilization medium; then the immobilization medium was 110cm 2 The filling amount per L is placed in a 20-ton reactor with a height-to-diameter ratio of 3:1. Then add the cultured bacteria into the fermenter equipped with 4 layers of grid plates (the feed pipes in the tank are arranged in a circle against the tank wall, and the circular pipes are drilled downwards to install a one-way nozzle. It is at an angle of 40° to the tangent direction of the circular pipeline, and the nozzle is at an angle of 35° to the horizontal plane), so that the outflowing liquid is in a spiral state downwards), with a flow rate of 15m 3 The / h cycle is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com