Fermentation preparation for straw decaying and preparing method of straw organic fertilizer

A technology of straw organic fertilizer and fermentation inoculum, which is applied in the field of fermentation, can solve the problems of adverse effects of soil microorganisms and soil physical and chemical properties, slow natural decomposing speed, etc., and achieves the effects of simple and easy preparation method and strong decomposing and decomposing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The prepared straw decomposing bacteria agent was used, and the experimental site was selected in Mishan Farm, Heilongjiang Province, and the previous stubble was corn. After harvesting, the full amount of straw is returned to the field, and the no-tillage method is implemented. There are 4 treatments in the experiment, the area of the plot is about 20m2 (4m×5m), and ridges are built between the plots, and the experiment is repeated 4 times. Field return + equal amount of water; No. 3: full amount of straw returned to the field; No. 4: no straw returned to the field. The experiment was repeated three times.

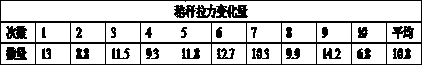

[0017] Analysis of test results

[0018] Color change of straw: 3 days after the application of microbial inoculants with decomposed straw and returned to the field, the color of the straw that was not applied basically did not change, and the straw was harder. However, the surface of the rice straw applied with the microbial inoculant of straw decomposing and ...

Embodiment 2

[0021] Embodiment 2: using the prepared straw decomposing bacterial agent, straw composting. The experimental site was selected at Jiansanjiang Farm in Heilongjiang Province, and the previous stubble was corn.

[0022] The first step is to use straw to build a 1.5-meter-high base after harvesting, and the width of the base is more than 4 meters.

[0023] The second step is to sprinkle water on the straw at the grassroots level. Sprinkle water evenly, and the amount of water sprinkled on grass-roots straw accounts for about 60% of the weight of grass-roots straw.

[0024] The third step is to spray bacteria and urea. Straw, bacterial agent, and urea need to be compatible according to a fixed ratio. In principle, 1 ton of straw: 2 kg of bacterial agent: 1 kg of urea, evenly sprinkled.

[0025] The fourth step is to cover the upper layer of straw with machinery, and sprinkle water while covering the straw, and the amount of watering for the second time reaches more than 60% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com