A circular arc internal and external chamfering machine

A technology of round chamfering and chamfering machine, which is applied in the direction of grinding machine tool parts, manufacturing tools, grinding drive devices, etc. It can solve problems such as inconsistency, affecting product quality, and adjusting flatness, so as to increase performance , High grinding uniformity and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

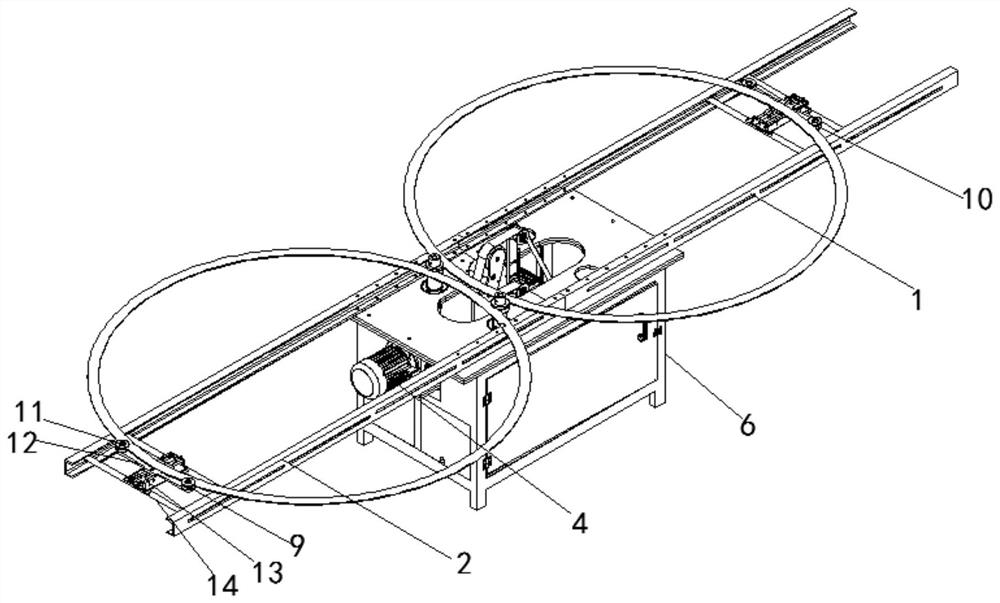

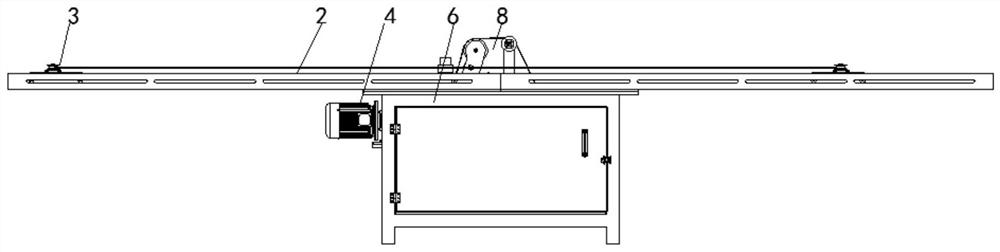

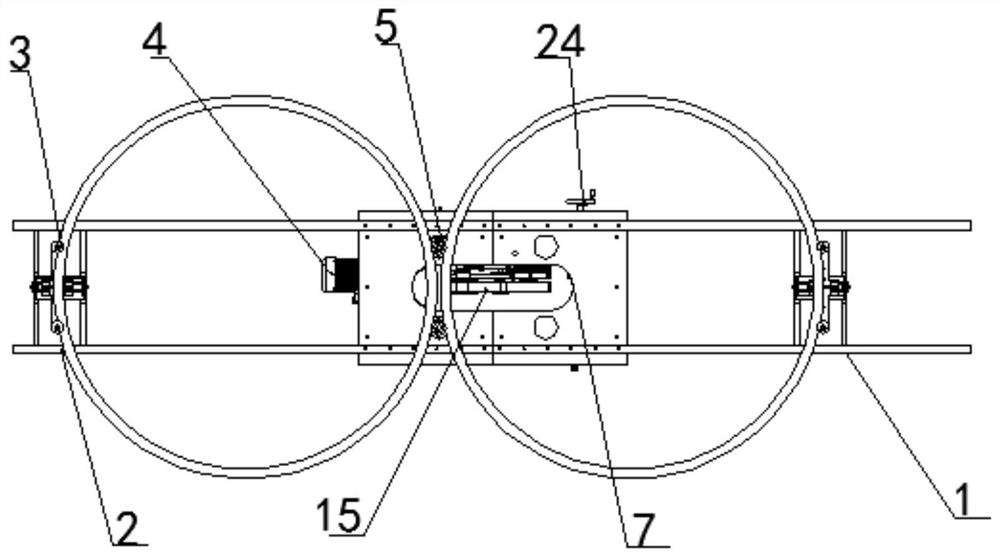

[0018] Refer to attached Figure 1-4 , an arc internal and external chamfering machine, comprising a workpiece internal chamfering rotary table 1, a workpiece external chamfering rotary table 2, a clamping mechanism 3, a first motor 4 and a rotating driving wheel 5, and the workpiece internal chamfering The angle turning table 1 and the workpiece outer circle chamfering turning table 2 are telescopically connected, and the rotating driving wheel 5 described on the cover plate is installed at the center between the two, and the rotating driving wheel 5 passes through the first A motor 4 drives and is fixedly connected with the workpiece inner circle chamfering turntable 1 and the workpiece outer circle chamfering turntable 2 respectively, and an annular through-hole groove 7 extending to the inside of the workbench 6 is opened on the cover plate And the chamfering grinding head mechanism 8 that is connected with the workpiece between the clamping mechanism 3 and the rotating dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com