Ammonia-containing waste gas ultralow nitrogen emission treatment method and system

A processing system, ultra-low nitrogen technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of biodegradation being easily affected by the environment, affecting degradation, and high cost, and achieving the benefits of the overall layout of the system, Good treatment effect and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

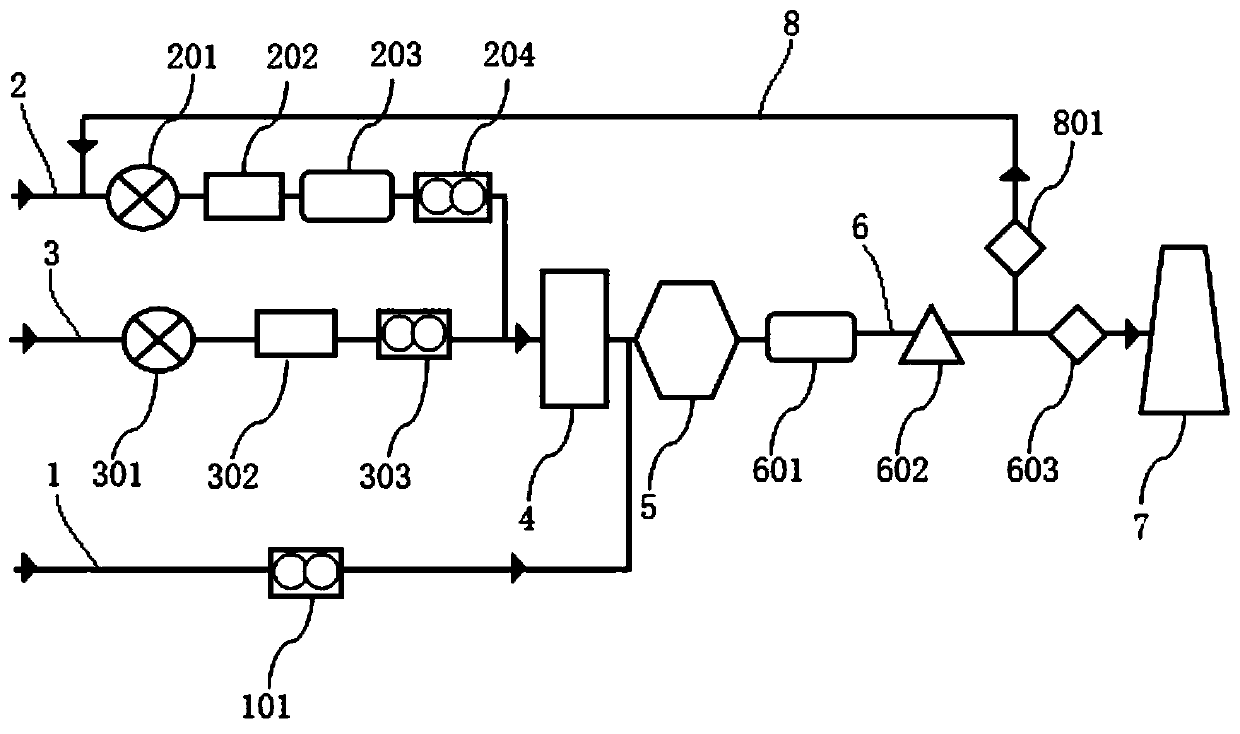

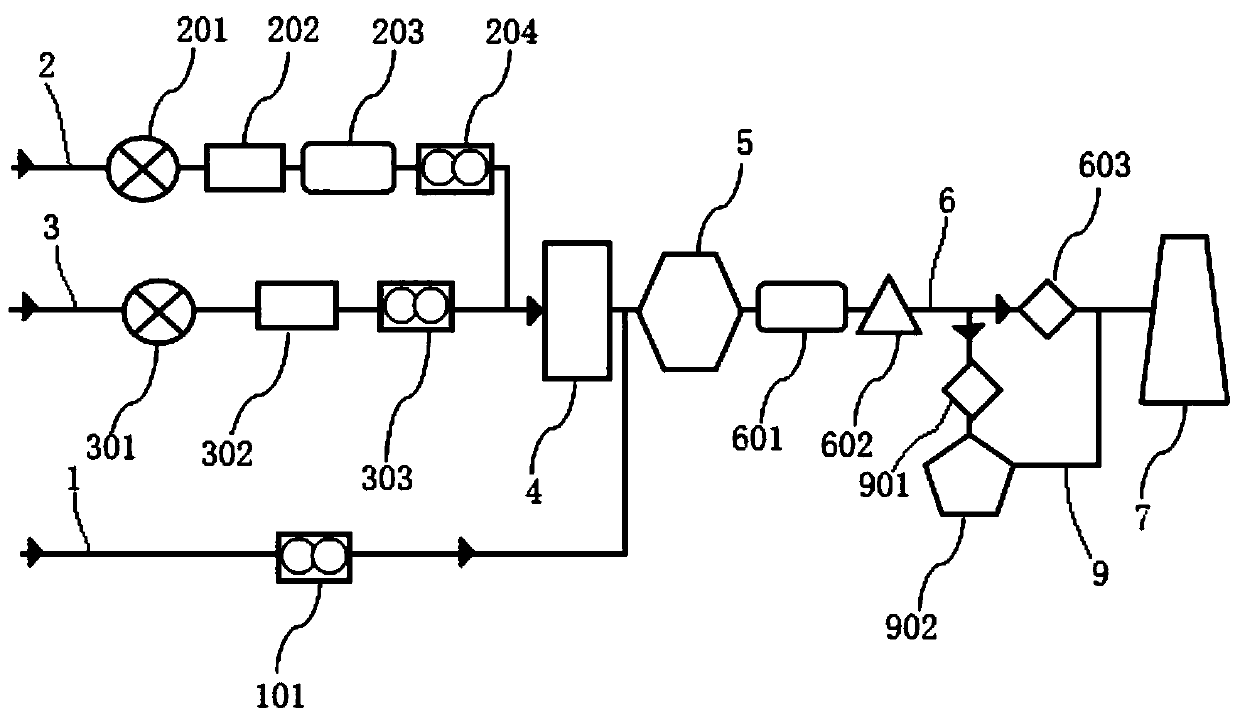

[0025] Such as Figure 1-Figure 3 As shown, a method for treating ammonia-containing waste gas with ultra-low nitrogen emissions described in the present invention comprises the following steps:

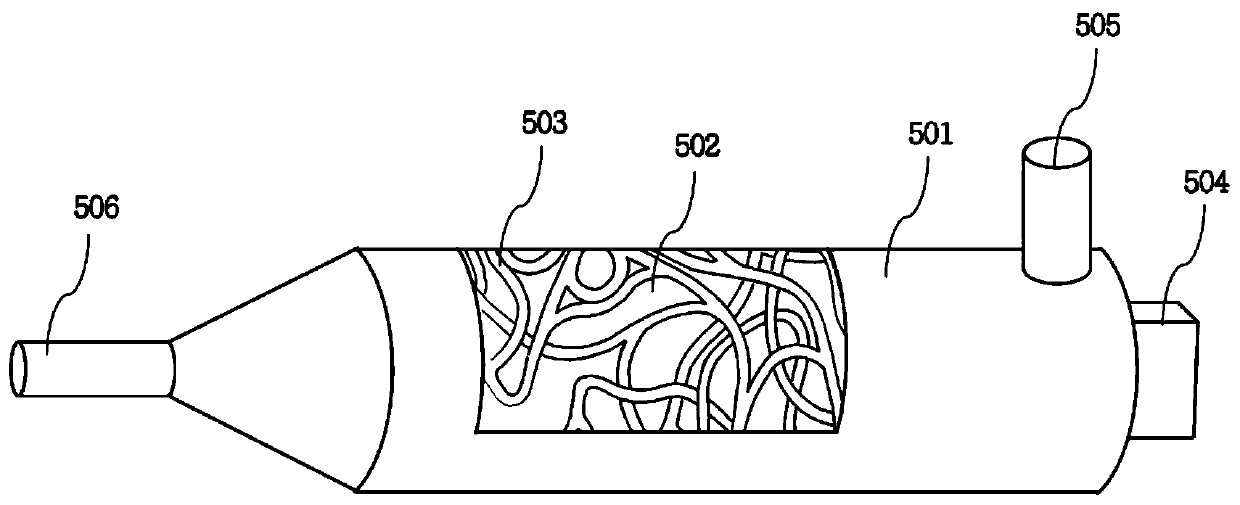

[0026] 1) The complex labyrinth channel reactor 5 is heated by the burner 504, such as image 3 As shown, the reactor body 501 of the complex labyrinth channel reactor 5 is provided with a regenerator 502, and a labyrinth channel 503 is reserved in the regenerator 502, and the labyrinth channel 503 revolves in the reactor body 501, and its ratio Surface area ≥ 1300m 2 / m 3 ;

[0027] 2) After the ammonia-containing waste gas and the oxygen-containing gas are mixed, they are passed into the complex labyrinth channel reactor 5 that has been heated to 900°C-1100°C, and the volume content of the ammonia gas in the mixed gas is kept at 2%-3%. The volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com