Antifouling coating composition, antifouling coating film, substrate with antifouling coating film, manufacturing method thereof, and antifouling method

A technology of antifouling coatings and compositions, applied in the direction of antifouling/underwater coatings, chemical instruments and methods, coatings, etc., can solve problems such as surface treatment without special mention, achieve good antifouling performance, inhibit antifouling The effect of reduced resistance and high base masking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0286] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples.

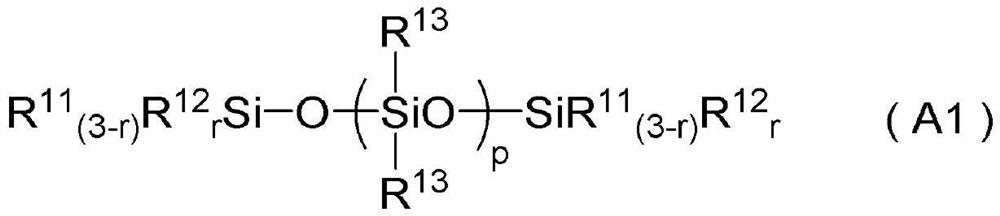

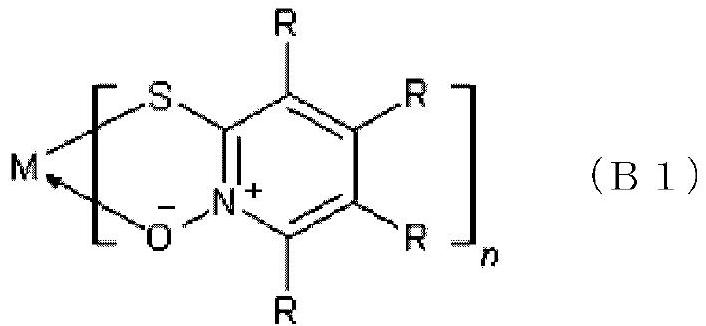

[0287] Hereinafter, curable organopolysiloxane (A) may be referred to as "(A) component", pyrithione salt (B) may be referred to as "(B) component", and titanium oxide (C) may be referred to as "( C) Ingredients", etc.

[0288] [Manufacture of Ether Group-Containing Polymer (F) Solution]

[0289]

[0290] The reaction was carried out under normal pressure and nitrogen atmosphere. In a reaction container equipped with a stirrer, a reflux cooler, a thermometer, a nitrogen introduction tube, and a dropping funnel, 42.86 g of methyl amyl ketone was charged, and heated while stirring until the inner temperature reached 100°C. While keeping the temperature of methyl amyl ketone in the reaction vessel within the range of 100±5°C, 20 g of NKEster AM-90G, 80 g of isobutyl acrylate, 2,2'-even A mixture consisting of 4 g of nitrogen bis(2-methylbuty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com