A core-shell structure silicon/carbon fiber flexible composite electrode material and its preparation method and application

A core-shell structure, composite electrode technology, applied in structural parts, battery electrodes, chemical characteristics of fibers, etc., can solve the problems of electrode structure rupture, electrochemical performance and flexibility degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

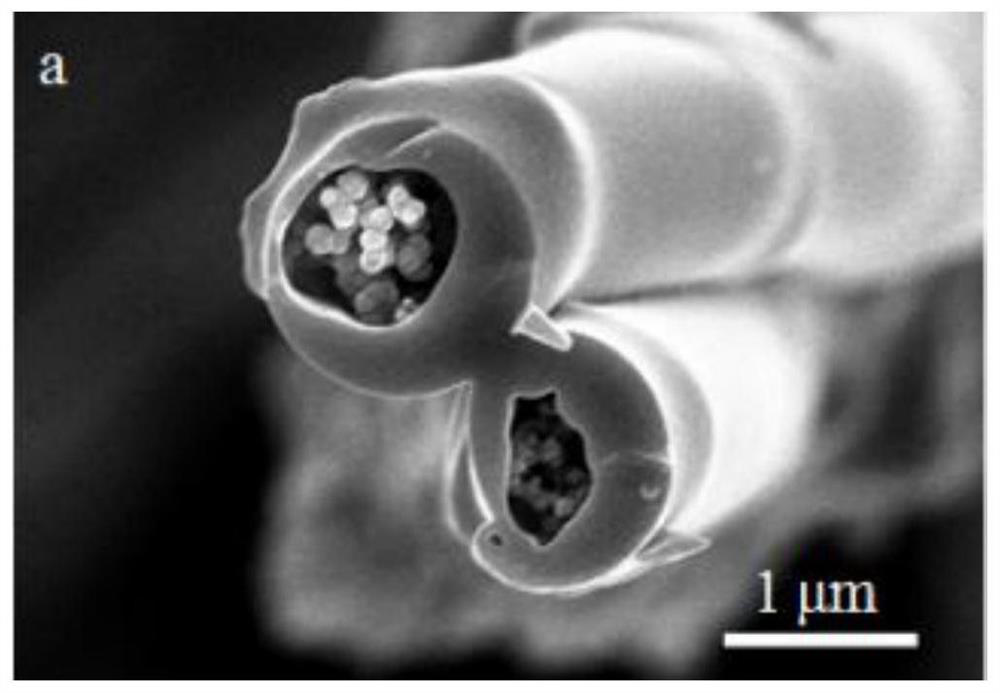

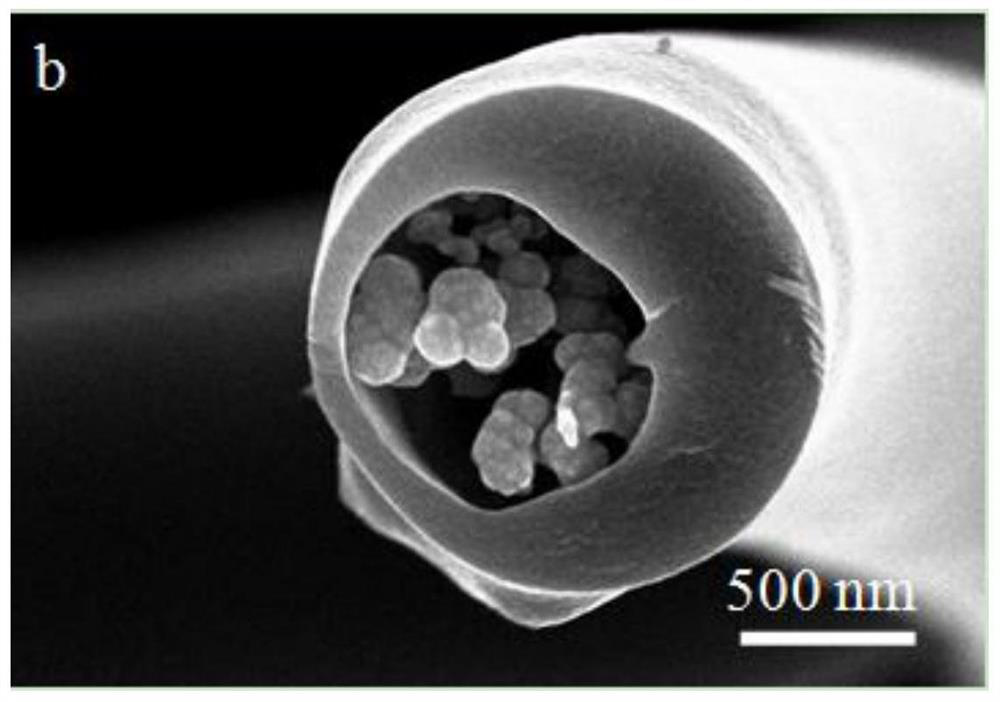

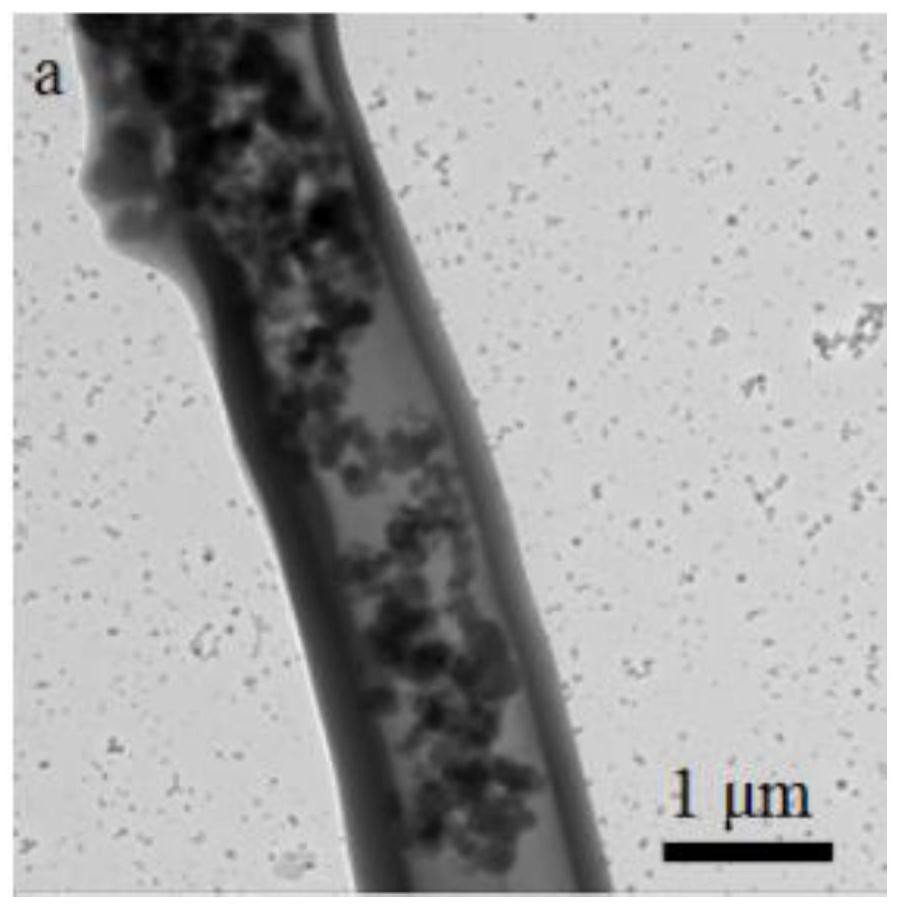

[0039] A core-shell structure silicon / carbon fiber flexible composite electrode material, which is made of core-shell structure silicon / carbon fiber through electrospinning. The core-shell structure silicon / carbon fiber uses nano-silicon particles as the core layer, and nano-silicon particles are evenly encapsulated in the carbon fiber shell layer. In it, the nano-silicon particles account for 5-15 wt% of the mass of the flexible composite electrode material.

Embodiment 2

[0041] A core-shell structure silicon / carbon fiber flexible composite electrode material, which is made of core-shell structure silicon / carbon fiber by electrospinning. The core-shell structure silicon / carbon fiber uses nano-silicon particles with a particle size of 50-100 nm as the core layer. The particles are uniformly encapsulated in the carbon fiber shell, wherein the nano silicon particles account for 5-15 wt% of the mass of the flexible composite electrode material.

Embodiment 3

[0043] A core-shell structure silicon / carbon fiber flexible composite electrode material, which is made of core-shell structure silicon / carbon fiber with a diameter of 1-2 μm through electrospinning, and the core-shell structure silicon / carbon fiber is made of nano-silicon particles with a particle size of 50-100nm It is the core layer, and the nano-silicon particles are evenly encapsulated in the carbon fiber shell layer, wherein the nano-silicon particles account for 5-15 wt% of the mass of the flexible composite electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com