Rapid vision measuring system and method for high-temperature forging line reconstruction size

A visual measurement and forging technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of slow processing speed, incomplete measurement data, and large amount of point data information, and achieve high reconstruction efficiency, accurate positioning and extraction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

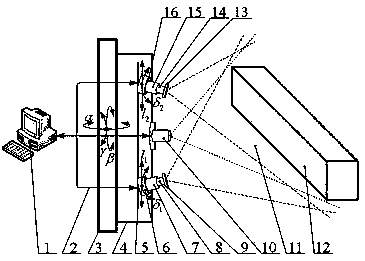

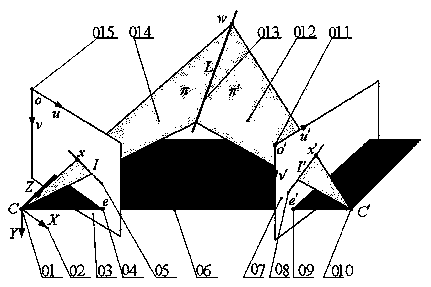

[0033] Such as figure 1 As shown, the binocular vision measurement system built in this embodiment mainly includes the following parts: high computer 1: used to process the motor control signal of the screw guide rail 5, the acquisition control signal of the left camera 15 and the right motor 7, and the pattern of the projector 10 Projection signal; signal line 2: for signal transmission between computer 1 and left camera 15, right motor 7, projector 10, screw guide rail 5 motors; camera frame 3: for supporting screw guide rail bracket 4, and driving The bracket 4 as a whole realizes the transformation of the pitch angle α, the flip angle β, and the rotation angle γ, and can move according to the size of the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com