A kind of preoxygenated fiber and preparation method thereof

A pre-oxygenated fiber, pre-oxidation technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of pre-oxygen fiber processability downstream products tear resistance, poor abrasion resistance, low pre-oxygen fiber strength, affecting products. performance and other issues, to achieve the effect of less fiber hole defects, improved processability, and large strength retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

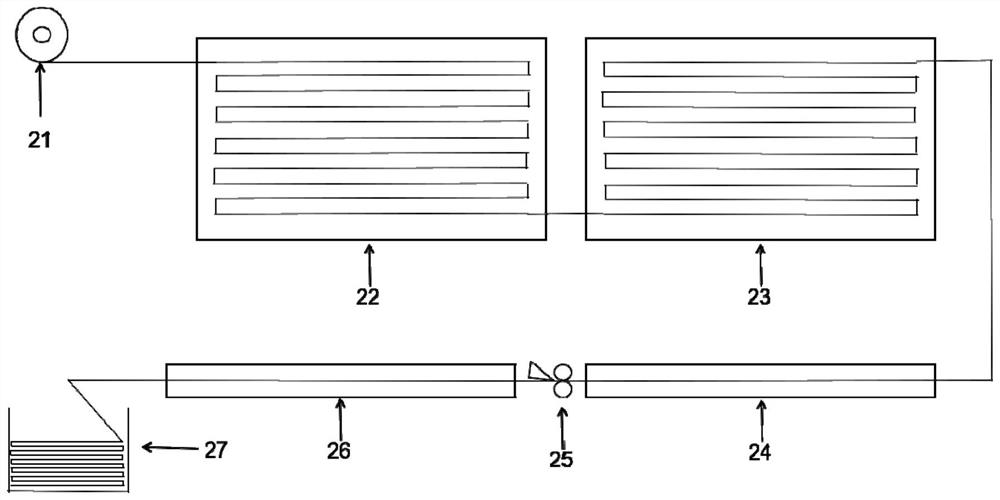

[0034] This embodiment provides a method of preparation of pre-oxide fibers, such as figure 2 As shown, the polyacrylonitrile yarn passes through the discharge device 21 into the first pre-oxidation furnace 22, and the first pre-oxidation furnace 22 temperature is 125 ° C, which is applied to 8%, and the treatment time is 60 minutes. Then, the second pre-oxidation furnace 23 was entered, and the second pre-oxidation furnace 23 was 235 ° C, which was applied to 2%, and the treatment time was 60 minutes. The temperature of the steam drafting device 24 is 100 ° C, which is applied to 2%. Adjust the pressure and spacing of the curled device 25 to reach the curl effect of 3 / cm. The drying type 26 is a hot air drying type, a hot air temperature of 80 ° C, and the drying time is 30 minutes. The back box has prepared pre-oxide fiber products.

[0035] The oil agent used by the raw material polypropylene nitrile raw wire is oleic acid (400) polyethylene glycol ester, and the oil content ...

Embodiment 2

[0037] This embodiment provides a method of preparation of pre-oxide fibers, such as figure 2As shown, the polyacrylonitrile yarn passes through the discharge device 21 into the first pre-oxidation furnace 22, and the first pre-oxidation furnace 22 temperature is 135 ° C, which is applied to 7%, and the treatment time is 60 minutes. Then, it entered the second pre-oxidation furnace 23, the second pre-oxidation furnace 23 temperature was 250 ° C, which was applied to 1.5%, and the treatment time was 60 minutes. The temperature of the steam drafting device 24 is 110 ° C, which is applied to 2%. Adjust the pressure and spacing of the curled device 25 to reach the curl effect of 3 / cm. The drying shaped device 26 is a hot air drying type, a hot air temperature of 100 ° C, and the drying time is 20 minutes. The back box has prepared pre-oxide fiber products.

[0038] The oil agent used by the raw material polypropylene nitrile raw wire is oleic acid (400) polyethylene glycol ester, an...

Embodiment 3

[0040] This embodiment provides a method of preparation of pre-oxide fibers, such as figure 2 As shown, the polyacrylonitrile yarn passes through the discharge device 21 into the first pre-oxidation furnace 22, and the first pre-oxidation furnace 22 temperature is 150 ° C, which is applied to 6%, and the treatment time is 45 minutes. Then, the second pre-oxidation furnace 23 was entered, and the second pre-oxidation furnace 23 was 260 ° C, which was applied to 1%, and the treatment time was 45 minutes. The temperature of the steam drafting device 24 is 100 ° C, which is applied to 2%. Adjust the pressure and spacing of the curled device 25 to reach the curl effect of 5 / cm. The drying shaped device 26 is a hot air drying type, a hot air temperature of 120 ° C, and the drying time is 10 minutes. The back box has prepared pre-oxide fiber products.

[0041] The oil agent used by the raw material polypropylene nitrile raw wire is a polyoxycetate lae-9, and the oil content is 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com