One-component negative-temperature early strength cement-based repair mortar

A warm-early-strength type and repairing mortar technology, which is applied in the field of ground building materials, can solve problems such as abnormal cement condensation, failure to reach the ground repair, and mortar expansion, and achieve the effect of satisfying mechanical properties, high construction efficiency, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

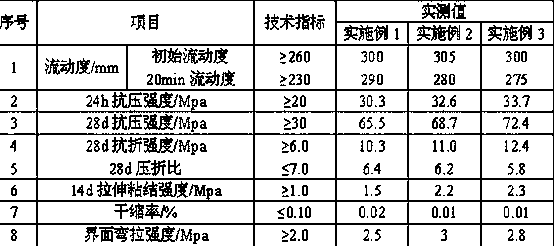

Examples

Embodiment 1

[0038] The one-component negative temperature early-strength cement-based repair mortar in this embodiment includes the following components in weight percentage: 35% special cement, 8% ordinary Portland cement, 2% anhydrite, 1% silica fume, and 49.99% quartz sand %, early strength agent 0.5%, antifreeze agent 2%, water reducer 0.2%, redispersible latex powder 1.2%, water retention thickener 0.01%, defoamer 0.1%. When stirring, the amount of mixing water added is 12.0% of the weight of the above dry-mixed mortar, and the water temperature is 20°C.

Embodiment 2

[0040] The single-component negative temperature early-strength cement-based repair mortar in this embodiment includes the following components in weight percentage: 38% of special cement, 6% of ordinary Portland cement, 3% of anhydrite, 1.5% of silica fume, and 47.732% of quartz sand %, early strength agent 1%, antifreeze agent 2.5%, water reducer 0.3%, redispersible latex powder 1.8%, water retention thickener 0.018%, defoamer 0.15%. When stirring, the amount of mixing water added is 12.5% of the weight of the above dry-mixed mortar, and the water temperature is 20°C.

Embodiment 3

[0042] The single-component negative temperature early-strength cement-based repair mortar in this embodiment includes the following components in weight percentage: 40% special cement, 4% ordinary Portland cement, 5% anhydrite, 2% silica fume, and 41.775% quartz sand %, early strength agent 1.5%, antifreeze agent 3%, water reducer 0.5%, redispersible latex powder 2%, water retention thickener 0.025%, defoamer 0.2%. When stirring, the amount of mixing water added is 12.5% of the weight of the above dry-mixed mortar, and the water temperature is 20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com