Making technology of canned tuna with salted egg yolk taste

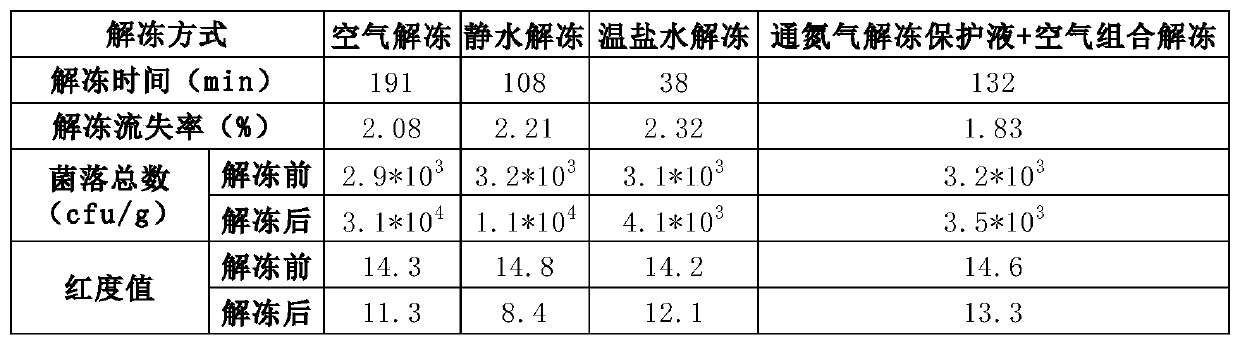

A production process and technology for tuna, which are applied in the fields of using chemicals to preserve meat/fish, food ingredients as antioxidants, and food ingredients as taste improvers, etc., can solve the problems of poor product flavor, long operation time, complicated operation, etc. Avoid or reduce oxidation, improve product quality, and improve the effect of thawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A process for making salted egg yolk-flavored canned tuna, comprising the following steps:

[0060] (1) Thawing: Soak the frozen tuna in the thawing protection solution at 5°C. During the immersion, nitrogen gas is passed into the thawing protection solution for bubbling until the central temperature of the tuna reaches -3°C. Thaw in the air at ℃ until the center temperature of the tuna reaches 3℃, the mass ratio of tuna to the thawing protection solution is 1:5, and the thawing protection solution is composed of the following components in mass percentage: 1% sodium polyacrylate, 0.015% vegetable Sodium acid, 0.3% citric acid, the balance is water;

[0061] (2) Finishing: After removing the head, tail, viscera, skin and bones of the tuna, wash it with clean water, cut it into fish pieces of the required size, drain the water, and control the temperature of the clean water at 10°C;

[0062] (3) Soft stirring and rinsing: place the fish pieces in a rinsing tank equipped...

Embodiment 2

[0069] A process for making salted egg yolk-flavored canned tuna, comprising the following steps:

[0070](1) Thawing: Soak the frozen tuna in the thawing protection solution at 3°C. During the immersion, nitrogen gas is passed into the thawing protection solution for bubbling until the central temperature of the tuna reaches -5°C, then fish out and place at 10°C. Thaw in the air at ℃ until the center temperature of the tuna reaches 0℃, the mass ratio of tuna to the thawing protection solution is 1:3, and the thawing protection solution is composed of the following components in mass percentage: 0.5% sodium polyacrylate, 0.01% vegetable Sodium acid, 0.2% citric acid, the balance is water;

[0071] (2) Finishing: remove the head, tail, viscera, skin and bones of the tuna, wash it with water, cut it into fish pieces of the required size, drain the water, and control the temperature of the water at 0°C;

[0072] (3) Soft stirring and rinsing: place the fish pieces in a rinsing t...

Embodiment 3

[0079] A process for making salted egg yolk-flavored canned tuna, comprising the following steps:

[0080] (1) Thawing: Soak the frozen tuna in a thawing protection solution at 4°C. During the immersion, nitrogen gas is introduced into the thawing protection solution for bubbling until the central temperature of the tuna reaches -4°C, then taken out and placed in 12 Thaw in air at ℃ until the center temperature of tuna reaches 2℃, the mass ratio of tuna to thawing protection solution is 1:4, and the thawing protection solution is composed of the following components in mass percentage: 0.7% sodium polyacrylate, 0.012% vegetable Sodium acid, 0.25% citric acid, the balance is water;

[0081] (2) Finishing: After removing the head, tail, viscera, skin and bones of the tuna, wash it with clean water, cut it into fish pieces of the required size, drain the water, and control the temperature of the clean water at 7°C;

[0082] (3) Soft agitation and rinsing: place the fish pieces i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com