High strength hot rolled steel sheet and cold rolled steel sheet having excellent continuous productivity, high strength hot dip galvanized steel sheet having excellent surface quality and plating adhesion, and manufacturing method therefor

A kind of technology of hot-dip galvanized steel sheet and hot-rolled steel sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

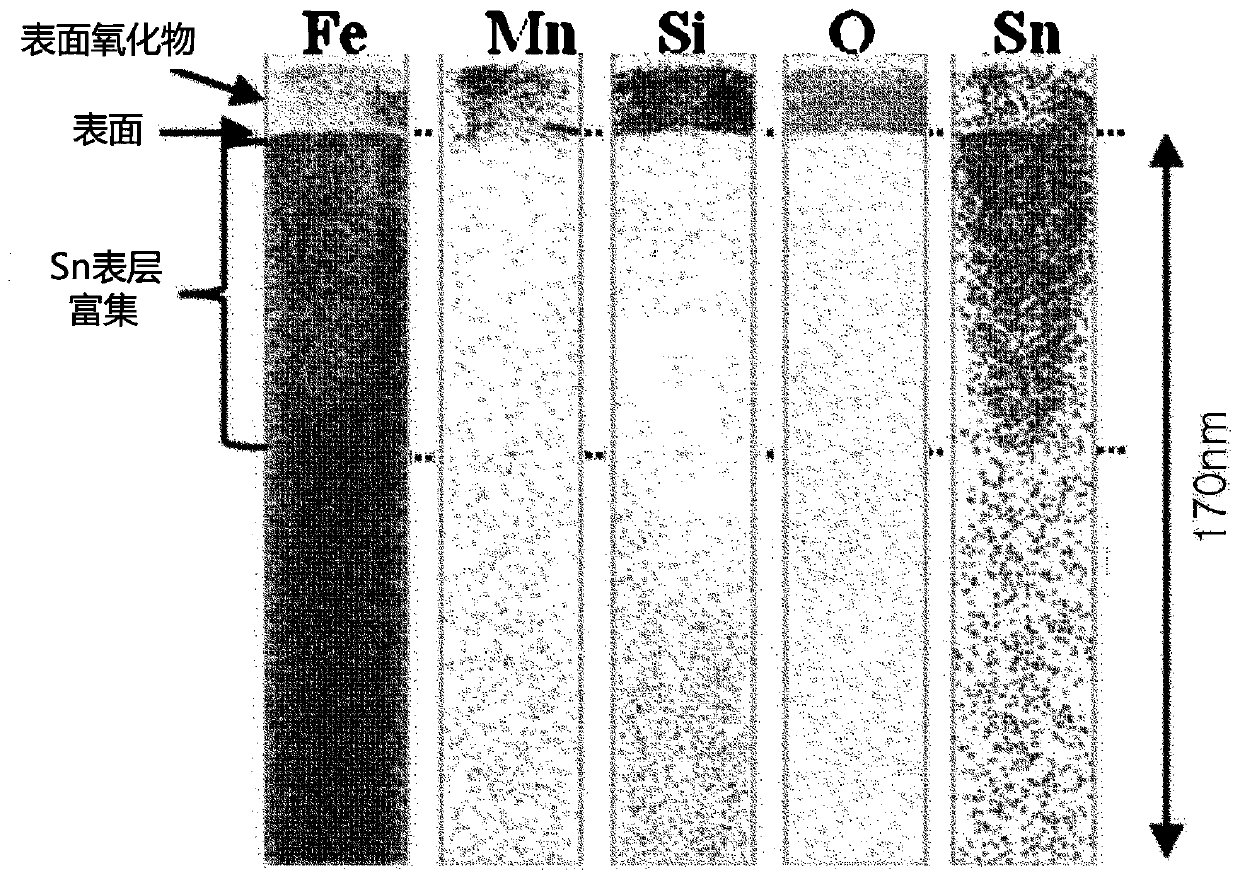

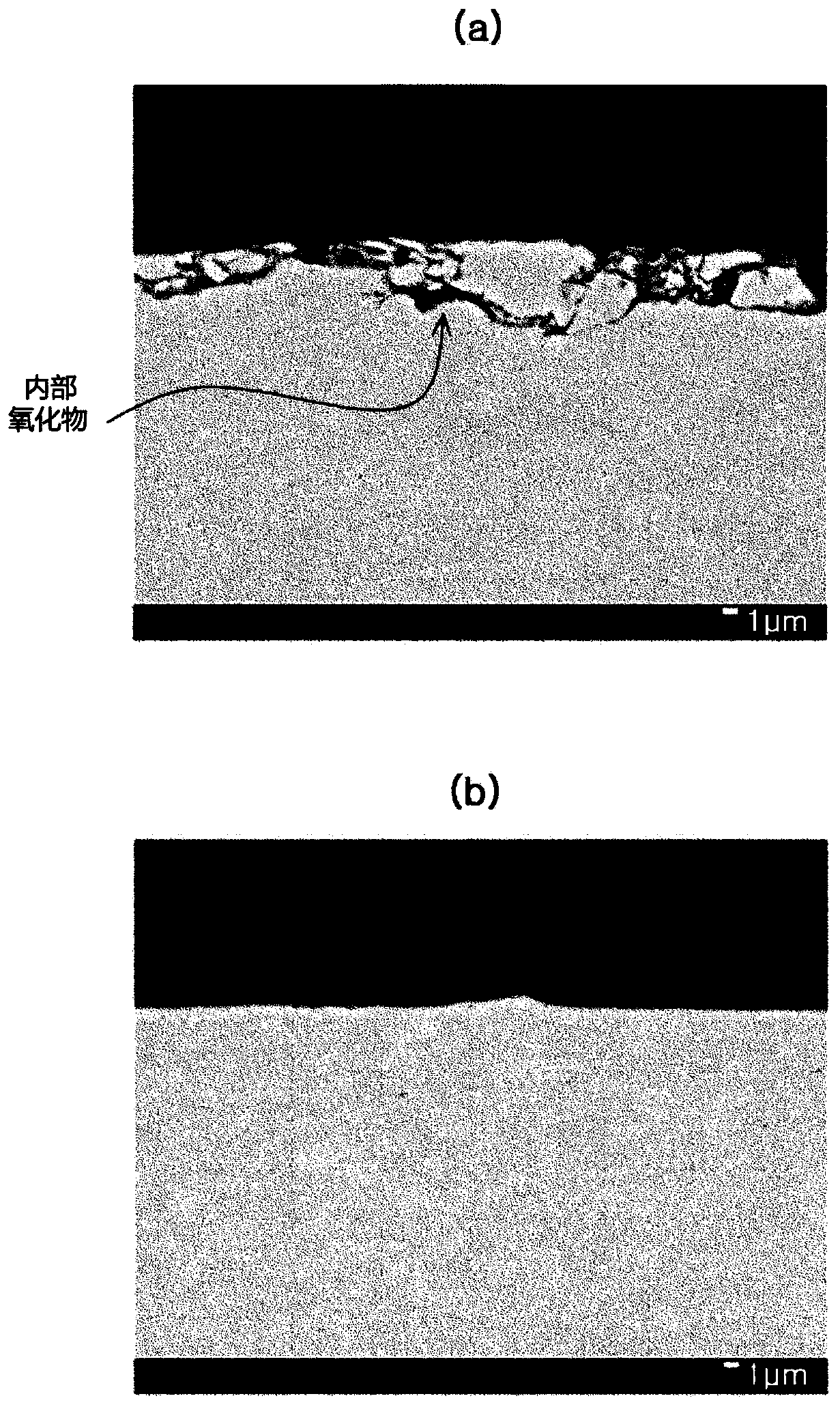

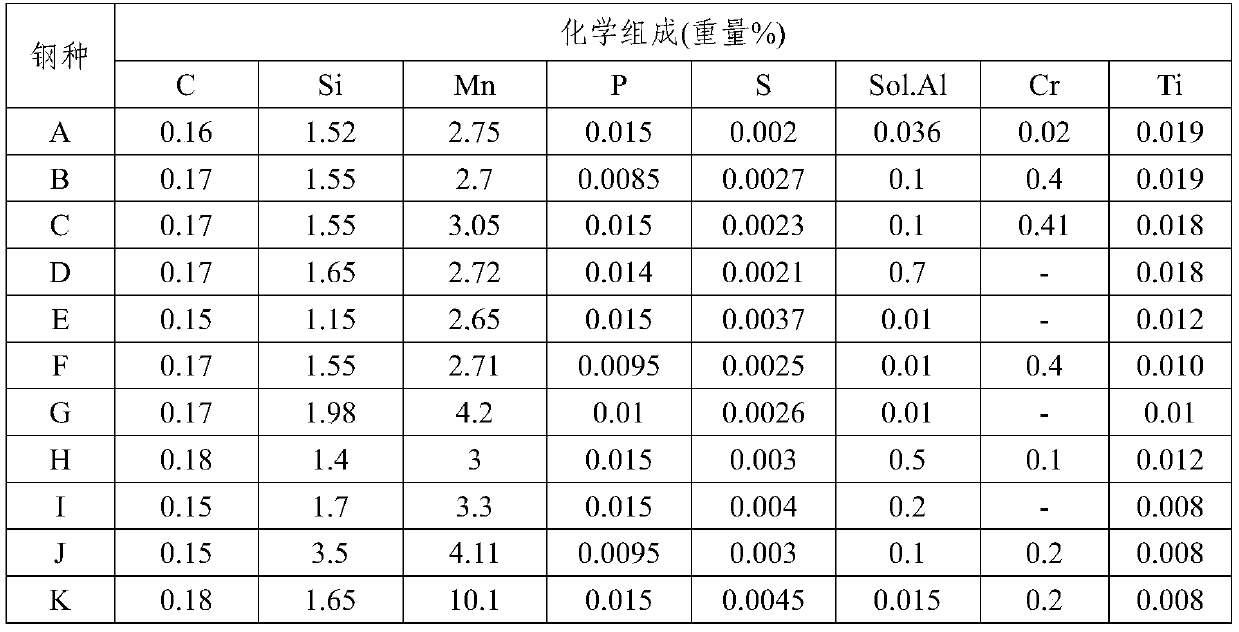

[0108] Billets having the compositions of Tables 1 and 2 below were reheated for 1 hour at a temperature of 1200° C. and finish rolled at a temperature of 900° C. higher than the Ar3 of all billets, and then cooled to Table 3 below. After the coiling temperature, it was forcibly cooled to a temperature of 550° C. at an average cooling rate of 3° C. / min, and then furnace cooled. With regard to the hot-rolled steel sheet that has been cooled, in order to observe the oxides inside the hot-rolled steel sheet, the cross-section of the steel sheet was observed with a scanning electron microscope. At this time, the maximum depth of the internal oxide of the hot-rolled steel sheet was measured at 5 places at a magnification of 5000, and the maximum depth among them was selected.

[0109] Then, the cooled hot-rolled steel sheet was pickled with a 17% by volume HCl solution at 60° C. for 40 seconds to dissolve iron oxide on the surface, and then cold-rolled at a rolling reduction of 45%...

Embodiment 2

[0150] In order to confirm the occurrence of dent defects while continuously producing products in the coil state, production and analysis are carried out in actual production facilities. The components having the compositions of the following Tables 6 and 7 were continuously cast, and steel slabs were produced. After keeping this billet at a temperature of 1200°C for 1 hour, finish rolling was performed at a temperature of 900°C higher than the Ar3 of all billets, cooled to the winding temperature shown in Table 8, and coiled as a coil, Then, it was forcibly cooled to a temperature of 550° C. at an average cooling rate of 3° C. / min, and then air-cooled.

[0151] With respect to the hot-rolled steel sheet cooled to normal temperature, the cross-section of the steel sheet was observed with a scanning electron microscope in order to observe oxides in the hot-rolled interior. At this time, the maximum depth of the internal oxide of the steel sheet was measured at 5 places at a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com