Electrostatic atomization milling fog drop transportation modeling and transportation effect evaluation method

An electrostatic atomization and evaluation method technology, applied in the field of milling processing, can solve the problems of slow calculation speed, difficult droplet diameter measurement, difficult to truly reflect the movement of the number of droplets, etc., and achieve the effect of simple and efficient convergence of the modeling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Take the electrostatic atomization milling of uncoated carbide milling cutters manufactured by SANDVIK as an example.

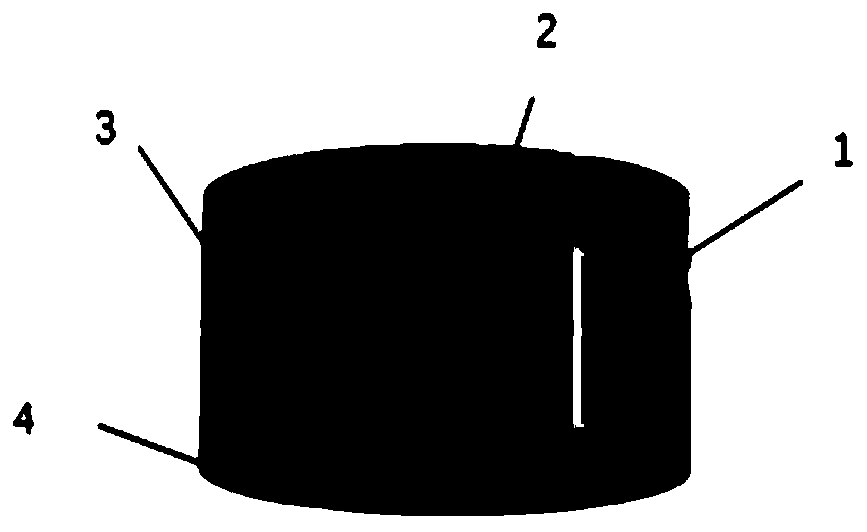

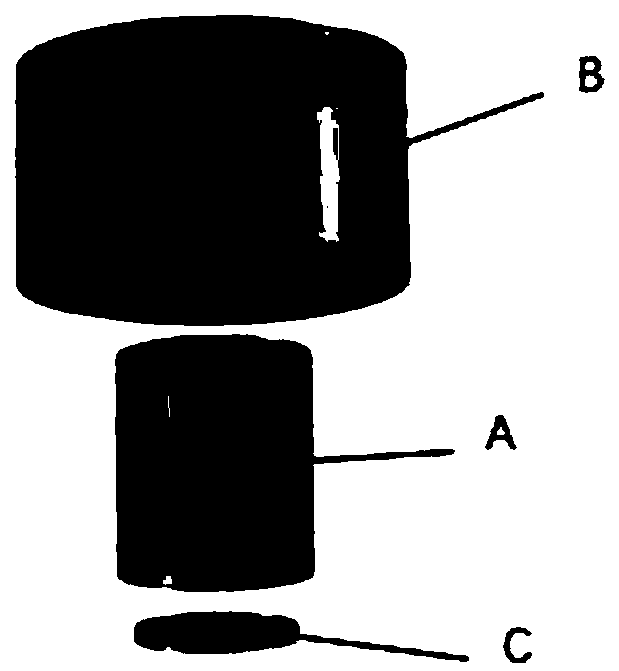

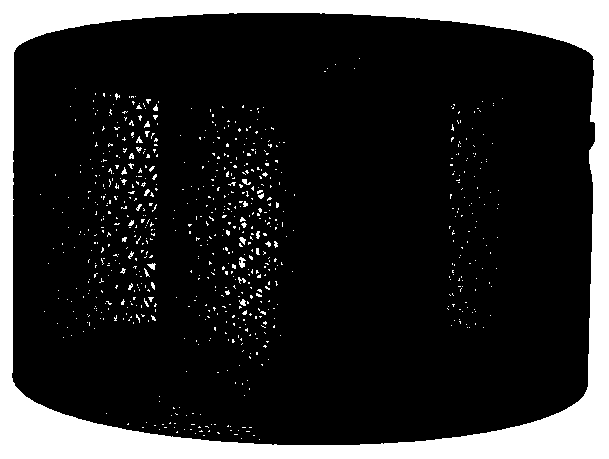

[0055] In the first step, establish as figure 1 In the 3D milling model shown, the solution domain is the torus-like region between the milling cutter and the nozzle. Such as figure 2 As shown, in order to facilitate analysis and calculation, the model is divided into three parts A, B, and C. Area A is a small ring close to the wall of the milling cutter, which is a rotation domain; area B is a large ring far away from the wall of the milling cutter. body, this part is the static area; area C is the target area (the area that needs to be cooled and lubricated according to the processing conditions), which can be used to count the droplets entering this area. A and B form an assembly, and C and A form a union. The modeling parameters of electrostatic atomization milling droplet transport in this embodiment are shown in Table 1.

[0056] Table 1 Mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com