Intelligent injection allocation device for manipulator in oilfield water injection room and control method of intelligent injection allocation device

An oil field water injection and manipulator technology, which is applied to earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of increased labor costs, laborious and time-consuming, manual adjustment of safety hazards, etc., to improve the degree of automation and reduce labor. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

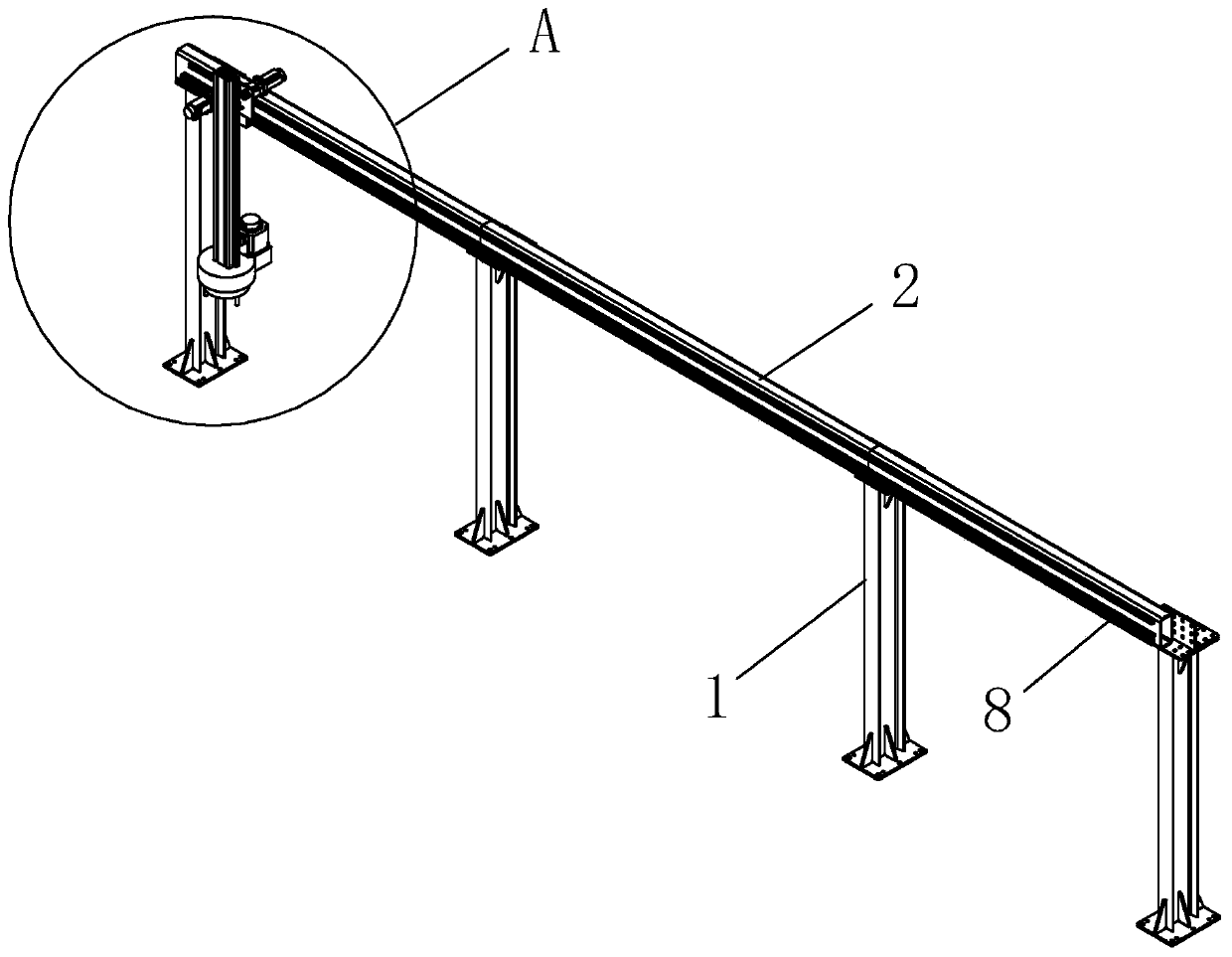

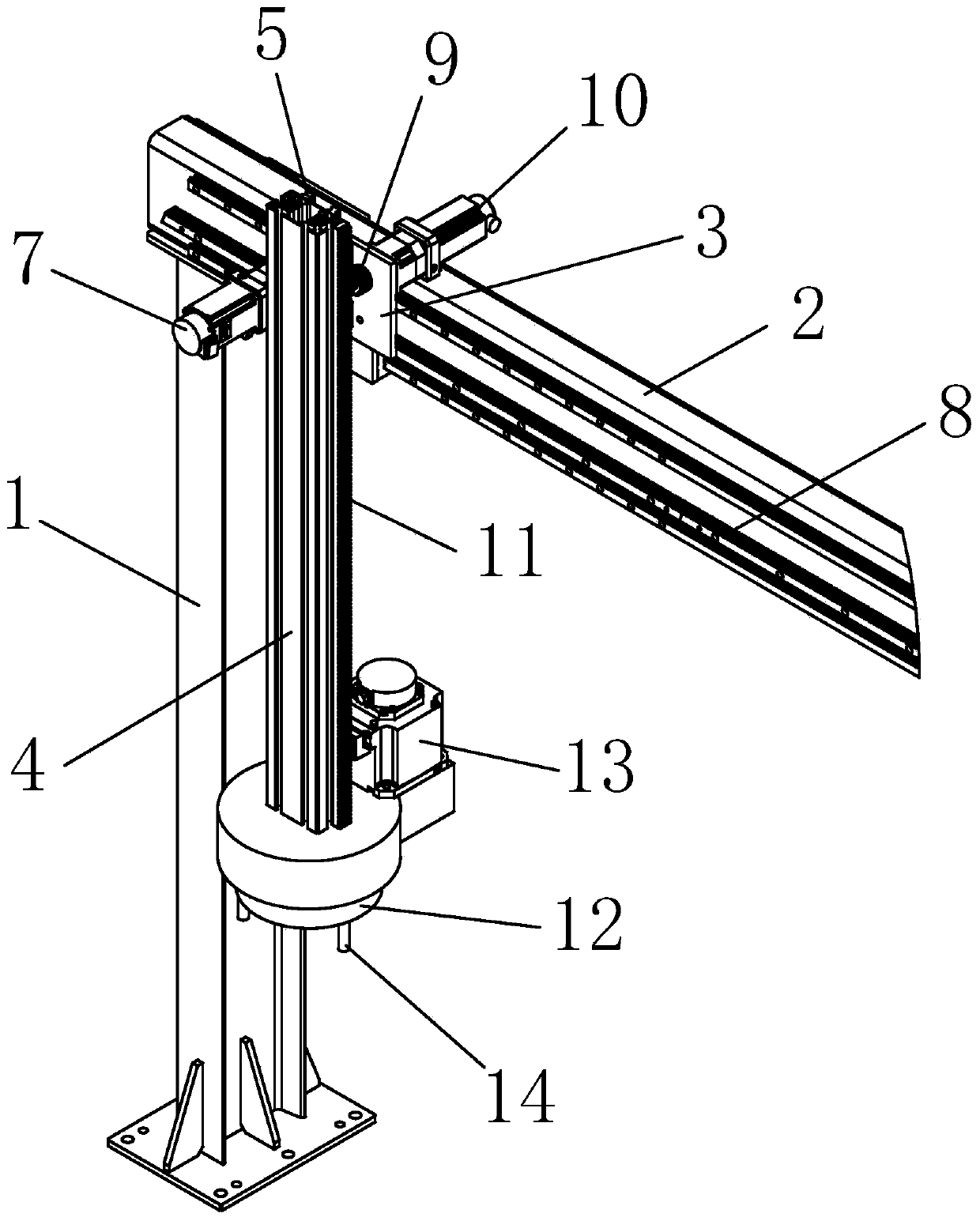

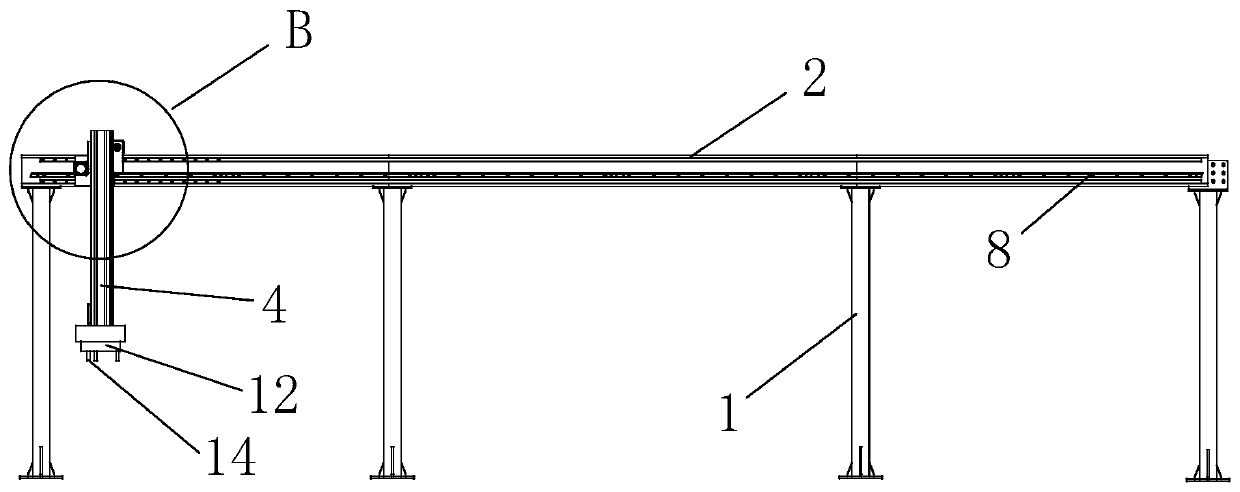

[0046] This embodiment is aimed at a water injection room with a single row of valves (such as Figure 10 As shown), a manipulator intelligent dispensing device in the oilfield water injection room is proposed to replace the manual adjustment of the opening of the water injection well valve, improve the adjustment accuracy, reduce labor and reduce labor intensity.

[0047] The manipulator intelligent dispensing device in the oil field water injection room of this embodiment includes a horizontal travel mechanism, a vertical lifting mechanism, a rotation adjustment mechanism, and a servo controller for controlling the work of the above-mentioned mechanisms, and the servo controller is connected to the adjustment control unit in the water injection room ; The rotation adjustment mechanism is installed on the horizontal walking mechanism through the vertical lifting mechanism.

[0048] In this embodiment, the adjustment control unit of the water injection room is connected to the...

Embodiment 2

[0082] like Figure 13 As shown, this embodiment is aimed at a water injection room with multiple rows of valves. The valves in the water injection room form an array structure. The difference from the horizontal running mechanism in Embodiment 1 is that the horizontal running mechanism in this embodiment is also the same as that in the first embodiment. A second horizontal guide rail 15 vertical to the horizontal guide rail 2, the first horizontal guide rail 2 is movably erected on the second horizontal guide rail 15 by the support frame 1, and the bottom end of the support frame 1 is provided with a third driving gear and is used for driving The third driving motor 16 of the third driving gear, the second horizontal guide rail 15 is provided with a second horizontal rack 17 matched with the third driving gear. By adding the second horizontal guide rail 15, the rotary adjustment mechanism can travel between multiple rows of valves, and realize random movement within the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com