Method for treating copper-nickel alloy electroplating wastewater in pyrophosphate-citric acid system

A technology of pyrophosphate, copper-nickel alloy, applied in the fields of metallurgical wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of unreachable copper and nickel, low efficiency of lemon root, high treatment cost, etc. To achieve the effect of simple process, low processing cost and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

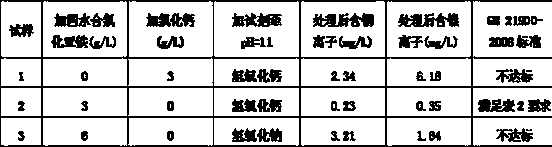

Examples

Embodiment 1

[0045] Embodiment 1: process the copper-nickel alloy electroplating wastewater containing potassium pyrophosphate 5000 mg / L

[0046] Step 1, add ferrous chloride and calcium chloride

[0047] The copper-nickel alloy electroplating wastewater is transported from the wastewater regulating tank to the feeding tank, the tank liquid is stirred with a mixer, and hydrochloric acid is added to adjust the pH to 6, and 15L of ferrous chloride solution and 35L of calcium chloride solution are added to each ton of wastewater.

[0048] Step 2. Precipitation of complexing agents and heavy metal ions

[0049] The wastewater in the feeding tank flows into the sedimentation tank, the tank liquid is stirred with a mixer, the pH is adjusted to 10-12 by adding lime emulsion, the ferrous ion and the calcium ion cooperate to precipitate citrate, and the calcium ion and pyrophosphate form calcium pyrophosphate precipitation, from the compound Copper ions and nickel ions released from the ions form ...

Embodiment 2

[0058] Embodiment 2: process the copper-nickel alloy electroplating wastewater containing potassium pyrophosphate 2000 mg / L

[0059] Step 1, add ferrous chloride and calcium chloride

[0060] The copper-nickel alloy electroplating wastewater is transported from the wastewater regulating tank to the feeding tank, the tank liquid is stirred with a mixer, the pH is adjusted to 6 by adding hydrochloric acid, and 8L of ferrous chloride solution and 15L of calcium chloride solution are added to each ton of wastewater.

[0061] Step 2. Precipitation of complexing agents and heavy metal ions

[0062] The wastewater in the feeding tank flows into the sedimentation tank, the tank liquid is stirred with a mixer, the pH is adjusted to 10-12 by adding lime emulsion, the ferrous ion and the calcium ion cooperate to precipitate citrate, and the calcium ion and pyrophosphate form calcium pyrophosphate precipitation, from the compound Copper ions and nickel ions released from the ions form pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com