Sewage plant scum separation treatment apparatus

A technology of separation treatment and sewage treatment plant, which is applied in the direction of water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. It can solve the problem that the sewage treatment plant does not have equipment to deal with large-scale scum, and achieve saving Manpower, satisfying large-area processing, high work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

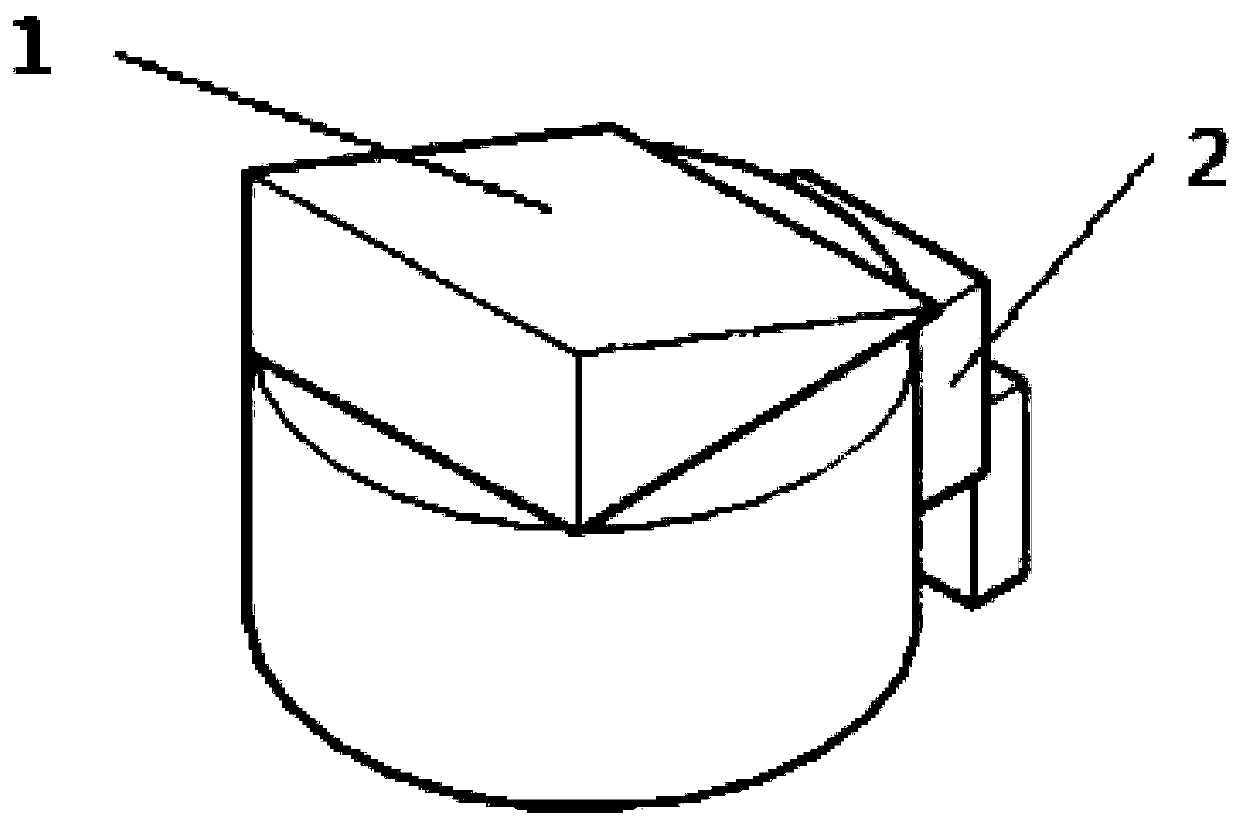

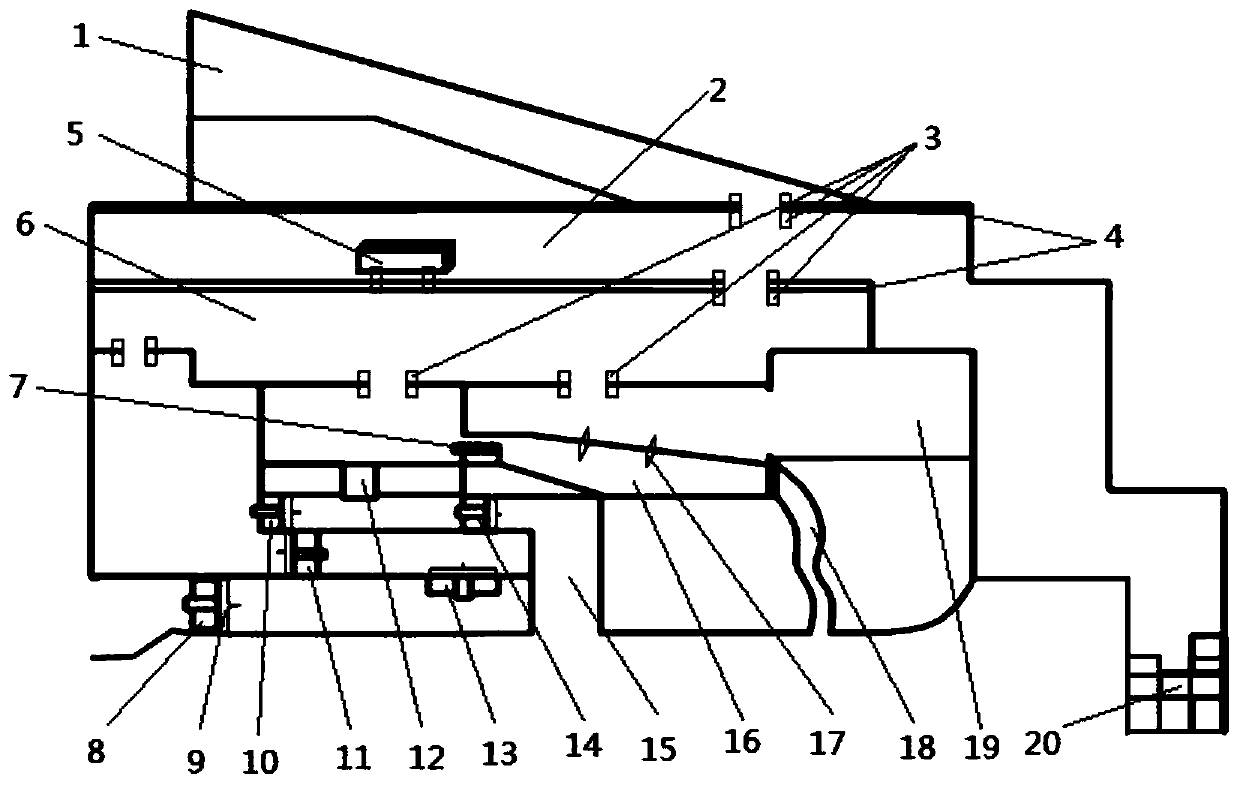

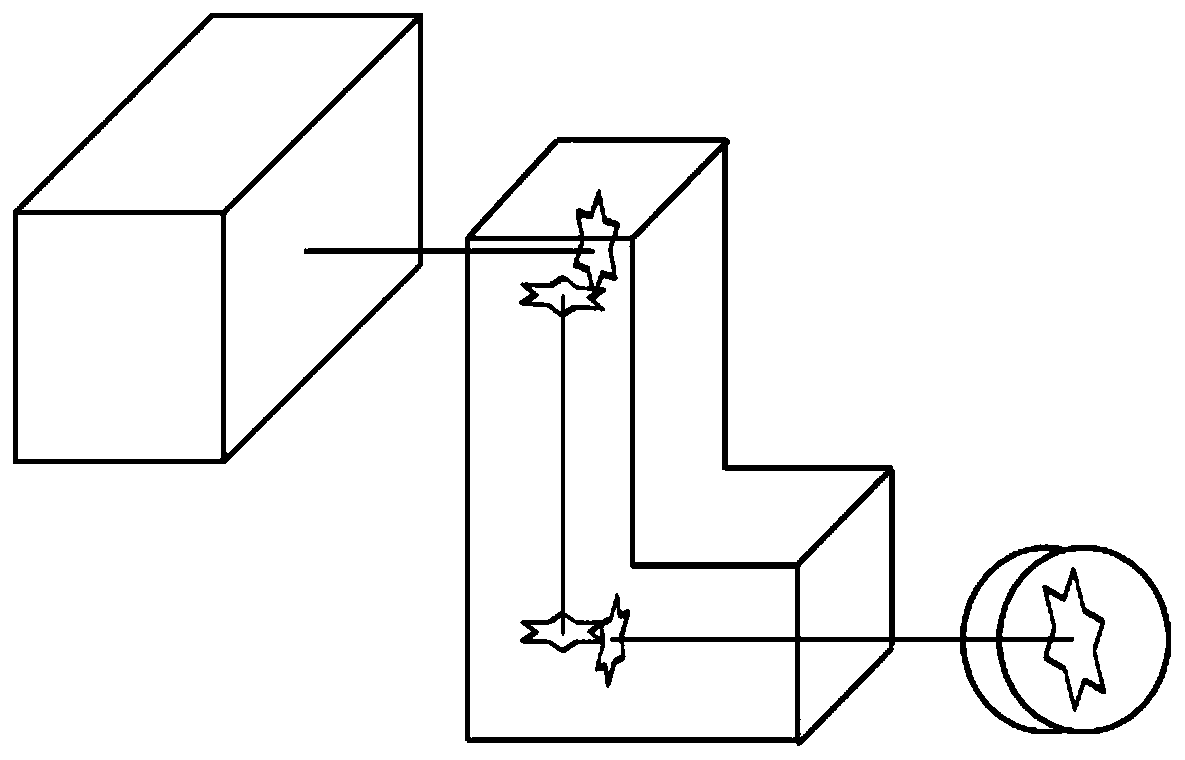

[0029] A sewage plant scum separation treatment device, including an outer cover 2, a battery 6, and a main body; the main body includes a cabin A and a cabin B; the outer cover 2 includes a horizontal end and a vertical end, and the bottom of the vertical end is provided with a propeller The motor A20, the storage battery 6 is located under the horizontal end, the main body is provided under the storage battery 6, the entrance is provided at the bottom of the cabin A, the turbo pump E8 is provided at the entrance, the storage room A is provided in the cabin A, the bottom of the storage room A is opened and at the opening A stirring and breaking machine 12 is provided, and the cabin B includes a defoamer storage chamber 19 and a defoamer cavity 16, the defoamer cavity 16 is located below the defoamer storage chamber 19, and the spray head 17 communicates with the defoamer storage chamber 19 and the defoamer storage chamber 19. The defoaming cavity 16 and the spray head 17 can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com