Method for continuously producing copper oxide

A technology of copper oxide and copper hydroxide, applied in copper oxide/copper hydroxide and other directions, can solve the problems of high energy consumption, low impurity content, and large human resource consumption, so as to improve production efficiency, simple and fast process flow effects of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

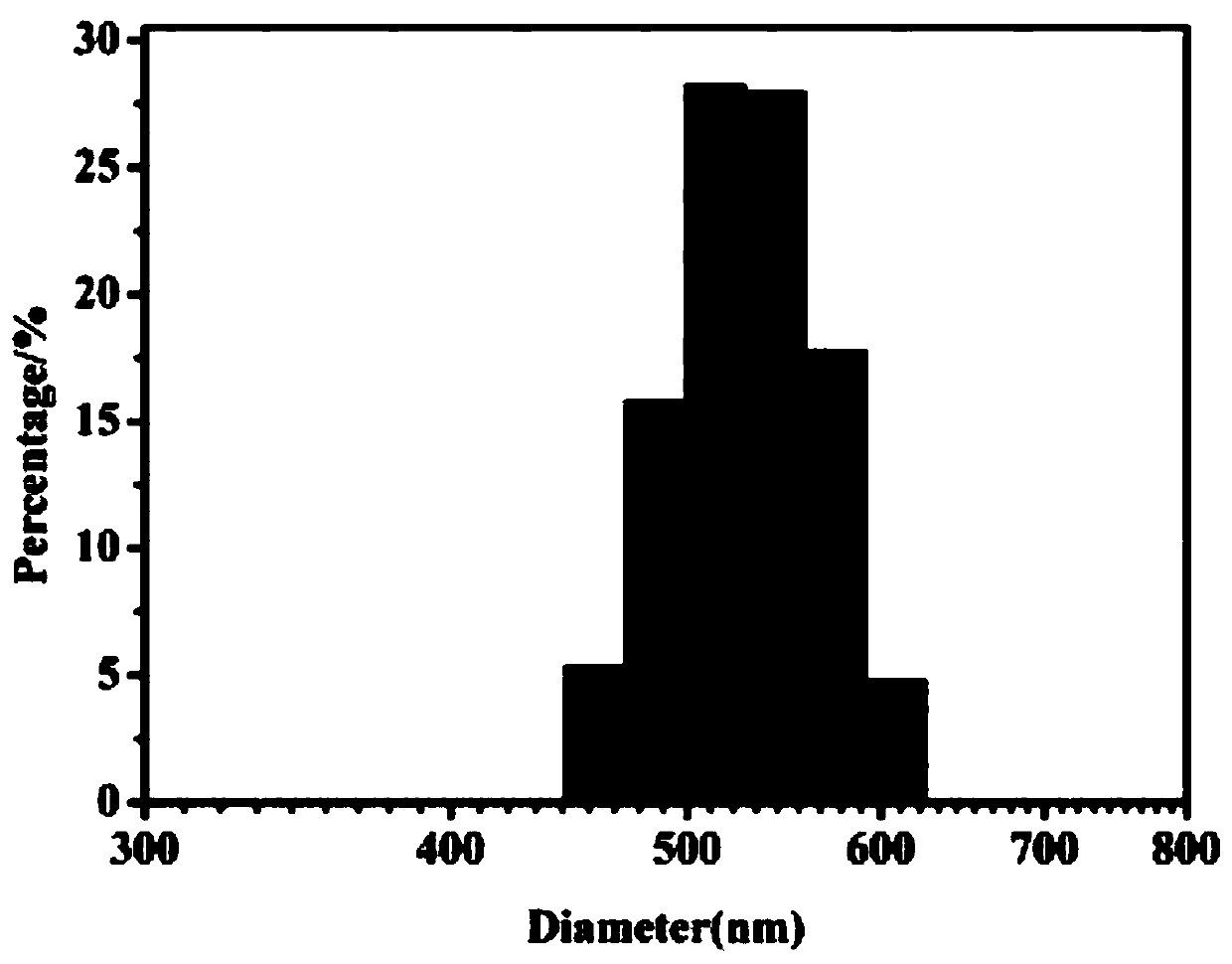

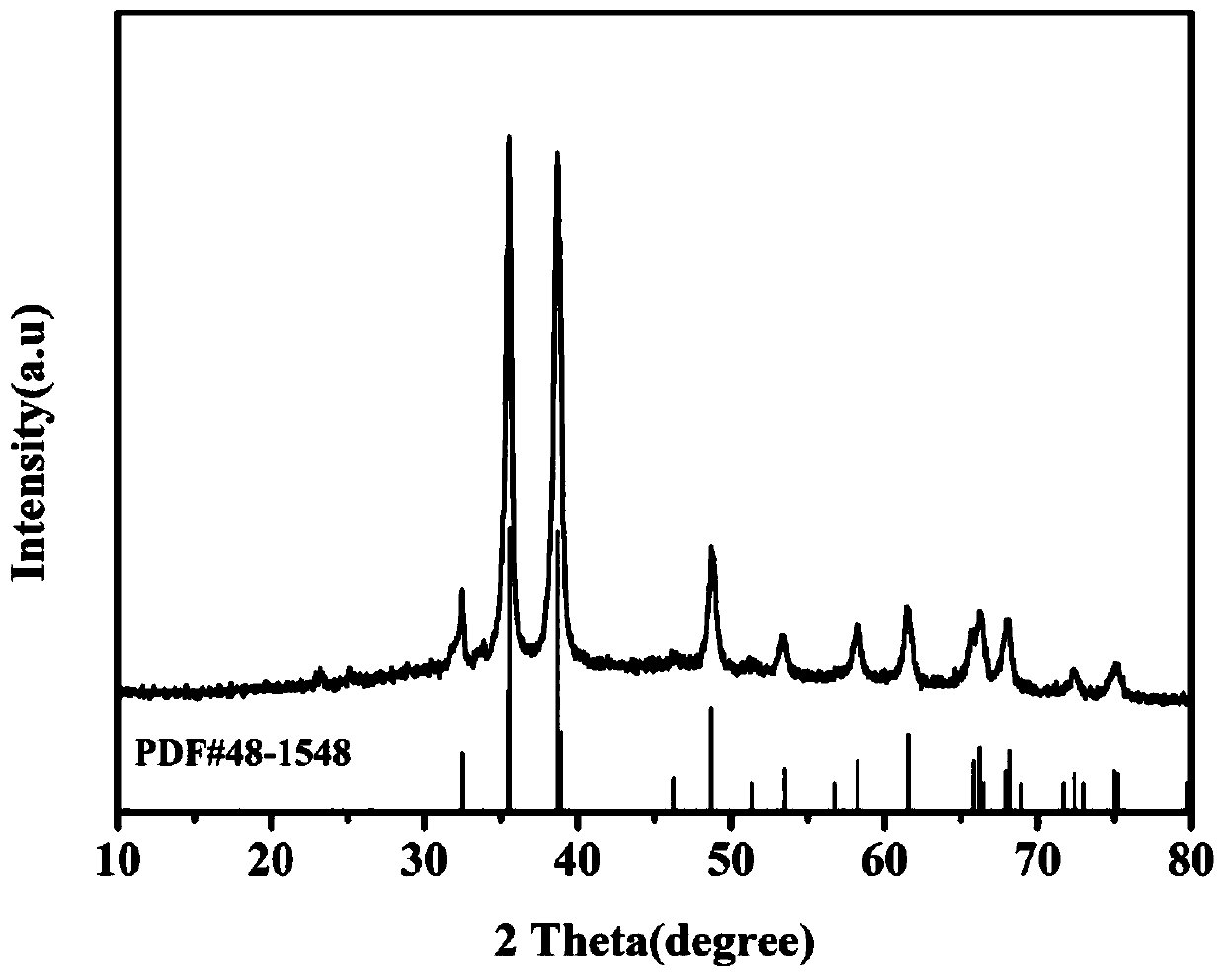

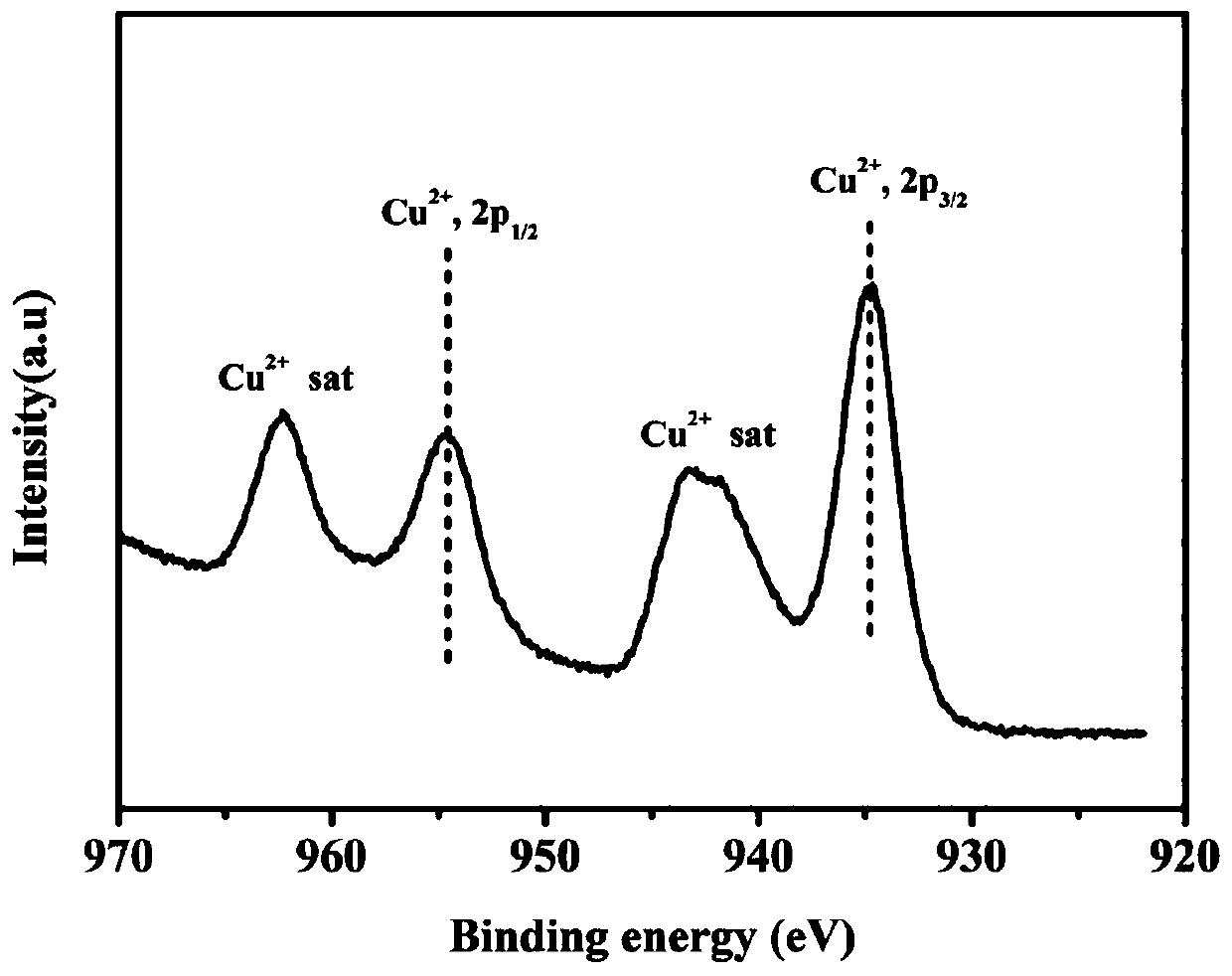

[0029] A kind of method for continuously producing copper oxide provided by the invention, comprises the following steps successively:

[0030] 1) 0.1mol / / L copper chloride solution and 0.1mol / L sodium hydroxide solution are continuously fed into the tubular reactor according to the molar ratio of copper ions and sodium ions at 2:1, and the length of the tubular reactor is 0.2m, after the described copper-containing solution and alkaline solution are mixed, the flow rate in the tubular reactor is 20L / (m 2 h);

[0031] 2) Under the condition of a pH value of 8, react in a tubular reactor to obtain a solution containing copper hydroxide, and use the heat of reaction to increase the temperature of the solution and partially decompose it into copper oxide;

[0032] 3) Continue heating to increase the reaction temperature to 60°C, and the copper hydroxide is further decomposed into copper oxide;

[0033] 4) The reacted product mixture was separated by a continuous centrifuge to o...

Embodiment 2

[0035] A kind of method for continuously producing copper oxide provided by the invention, comprises the following steps successively:

[0036] 1) 10mol / / L copper sulfate solution and 2.5mol / L sodium hydroxide solution are continuously passed into the tubular reactor according to the molar ratio of copper ion and sodium ion 2:1.1, the length of the tubular reactor is 20m, After described copper-containing solution and alkaline solution are mixed, flow velocity in tubular reactor is 1000L / (m 2 h);

[0037] 2) Under the condition of pH value 9, react in a tubular reactor to obtain a solution containing copper hydroxide, and use the heat of reaction to increase the temperature of the solution and partially decompose it into copper oxide;

[0038] 3) Continue heating to increase the reaction temperature to 95° C., and the copper hydroxide is further decomposed into copper oxide;

[0039] 4) The reacted product mixture was separated by a continuous centrifuge to obtain copper oxi...

Embodiment 3

[0041] A kind of method for continuously producing copper oxide provided by the invention, comprises the following steps successively:

[0042] 1) 3mol / / L copper acetate solution and 1.5mol / L potassium hydroxide solution are continuously passed into the tubular reactor according to the molar ratio of copper ion and potassium ion 2:1.3, the length of the tubular reactor is 15m, After described copper-containing solution and alkaline solution are mixed, flow velocity in tubular reactor is 600L / (m 2 h);

[0043] 2) Under the condition of a pH value of 14, react in a tubular reactor to obtain a solution containing copper hydroxide, and use the heat of reaction to increase the temperature of the solution and partially decompose it into copper oxide;

[0044] 3) Continue heating to increase the reaction temperature to 75° C., and the copper hydroxide is further decomposed into copper oxide;

[0045] 4) The reacted product mixture was separated by a continuous centrifuge to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com