Antique brick carving corner mold and preparation method thereof

An antique brick and corner technology, applied in the field of antique brick carving corner mould and preparation, can solve the problems of low production efficiency, labor-intensive, difficult mass production, etc., and achieve the effect of increasing strength and improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

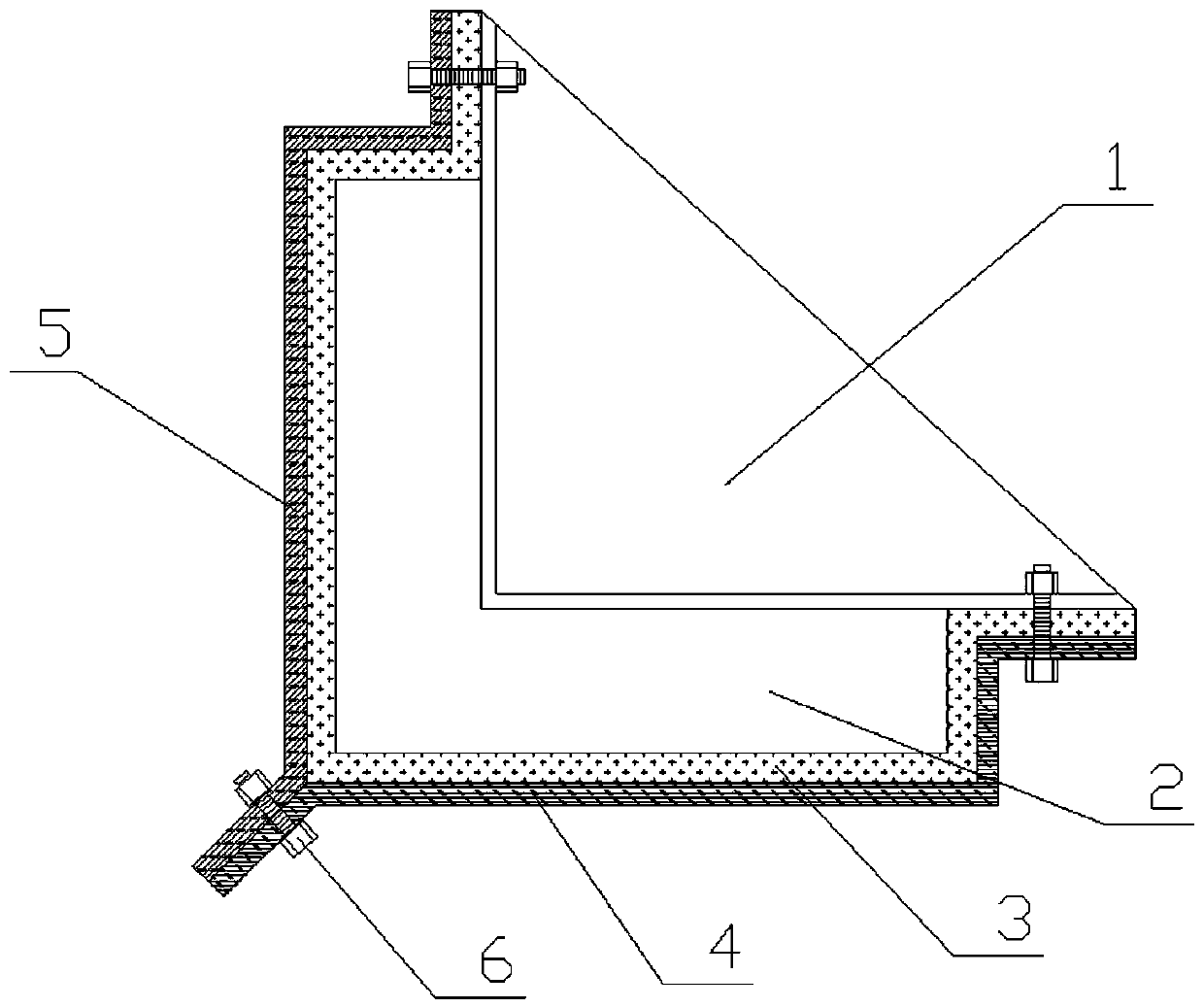

[0029] The preparation method of antique brick carving corner mould, is characterized in that following steps:

[0030] S1. Making sample molds: making corner mold blanks, correcting mold blanks, manually trimming mold blanks to the best shape, and obtaining standard sample molds;

[0031] S2. Making the silica gel layer: silica gel and catalyst are mixed at a weight ratio of 100:1.5 to make silica gel mucus; fix the sample mold on a right-angle support frame, apply the first layer of silica gel mucus until the entire sample mold is evenly covered, and place the first layer of gauze On the sample mold coated with silicone mucus, place small solid silica gel cuboids at even intervals around the sample mold to fix the supporting mold later, apply the second layer of silicone mucus until it is evenly covered, place the second layer of gauze, and then apply the third layer Silicone mucus until it is evenly covered, and then apply the release agent until it is evenly covered to obt...

Embodiment 2

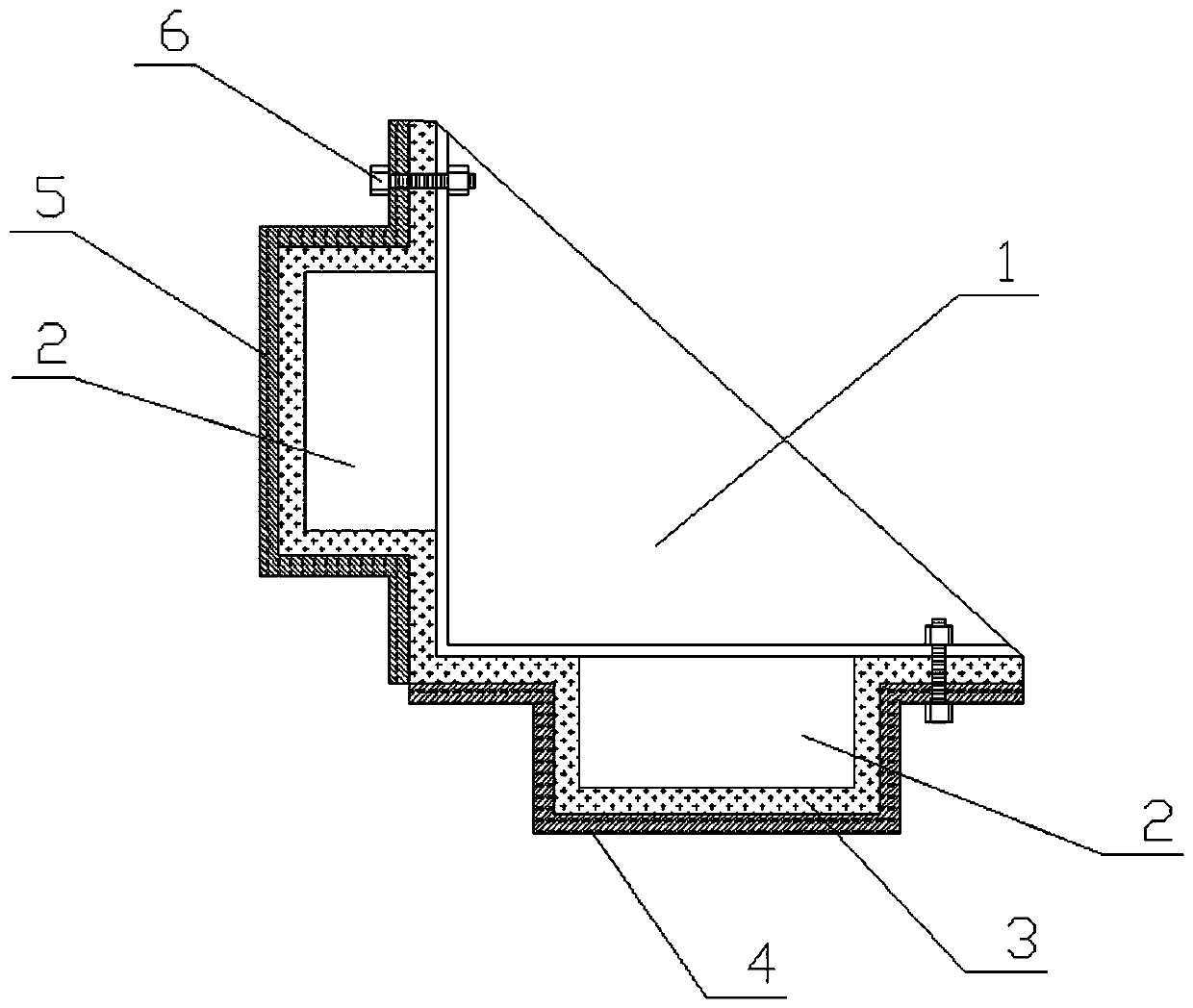

[0036] The preparation method of antique brick carving double-sided mold is characterized in that the following steps:

[0037] S1. Making sample molds: making two identical mold bases, correcting the mold bases, manually trimming the mold bases to the best shape, and obtaining two standard mold bases;

[0038] S2. Making the silica gel layer: silica gel and catalyst are mixed at a weight ratio of 100:1.8 to make silica gel mucus; respectively fix the sample molds on the two straight sides of the right-angle support frame, and apply the first layer of silica gel mucus until the entire mold is evenly covered , place the first layer of gauze on the sample mold coated with silicone mucus, place small solid silica gel cuboids around the sample mold at an even distance to fix the supporting mold later, apply the second layer of silicone mucus until it is evenly covered, and place the second layer of gauze , and then apply the third layer of silicone glue until it is evenly covered,...

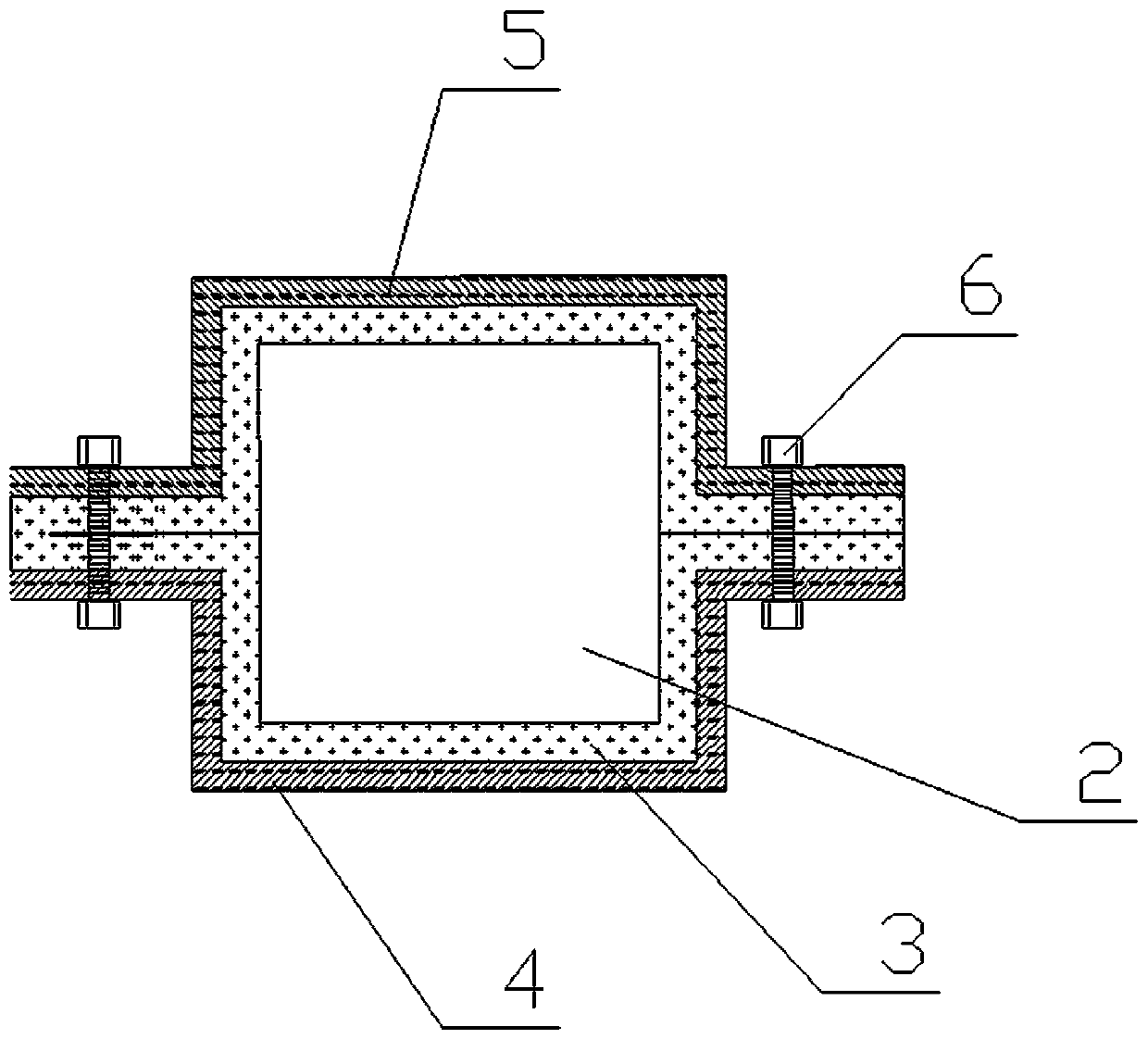

Embodiment 3

[0043] The difference from Example 1 is that silica gel and catalyst are mixed in a weight ratio of 100:2 to make silica gel mucus; resin, white water, blue water, light powder, and talcum powder are mixed in a weight ratio of 100:5:3:3:10 A resin mixture is made; the sample mold is a right-angled inner angle, and the outer angle is a variety of special-shaped carving shapes according to design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com