Magnetic conductive pad for magnetic template

A template and magnetic conduction technology, which is applied in the field of magnetic conduction pads, can solve the problems of bumping into the magnetic template, grinding the magnetic template, damage to the magnetic template, etc., and achieves the effects of convenient maintenance, low cost and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

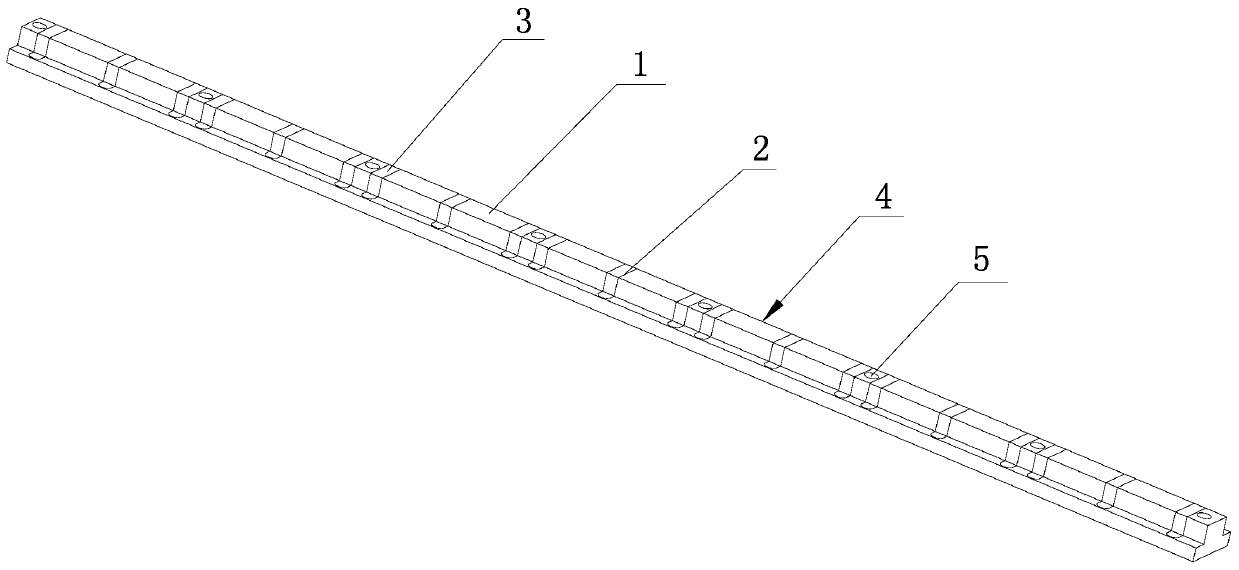

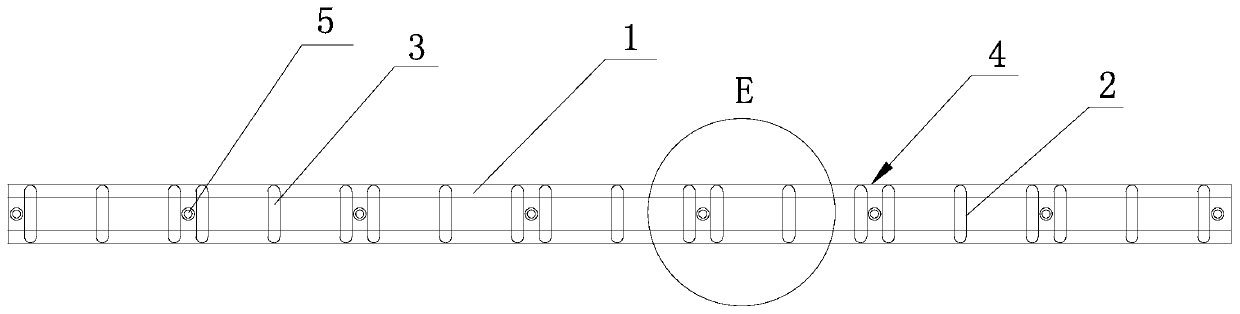

[0029] A magnetic pad suitable for a magnetic template proposed in this embodiment includes a magnetic conductor 1 whose longitudinal length is adapted to the magnetic template 8 and whose transverse section is in a "convex" shape. Generally, the longitudinal length of the magnetic conductor 1 is It can be designed so that its two ends are located outside the outermost magnetic pole 81 of the magnetic template 8, which is used as a fixed point for fixing the magnetic conductor 1 and the magnetic template 8, and the magnetic conductor 1 corresponds to each resin layer 82 on the magnetic template 8 A through-hole 2 that runs through the top and bottom and has hole walls on both sides is opened in the horizontal direction at the position. The through-hole 2 is poured with a non-magnetic material and forms a non-magnetic body 3 after the non-magnetic material is completely hardened. The non-magnetic body 3 The outer surface is flush with the outer surface of the magnetizer 1, and t...

Embodiment 2

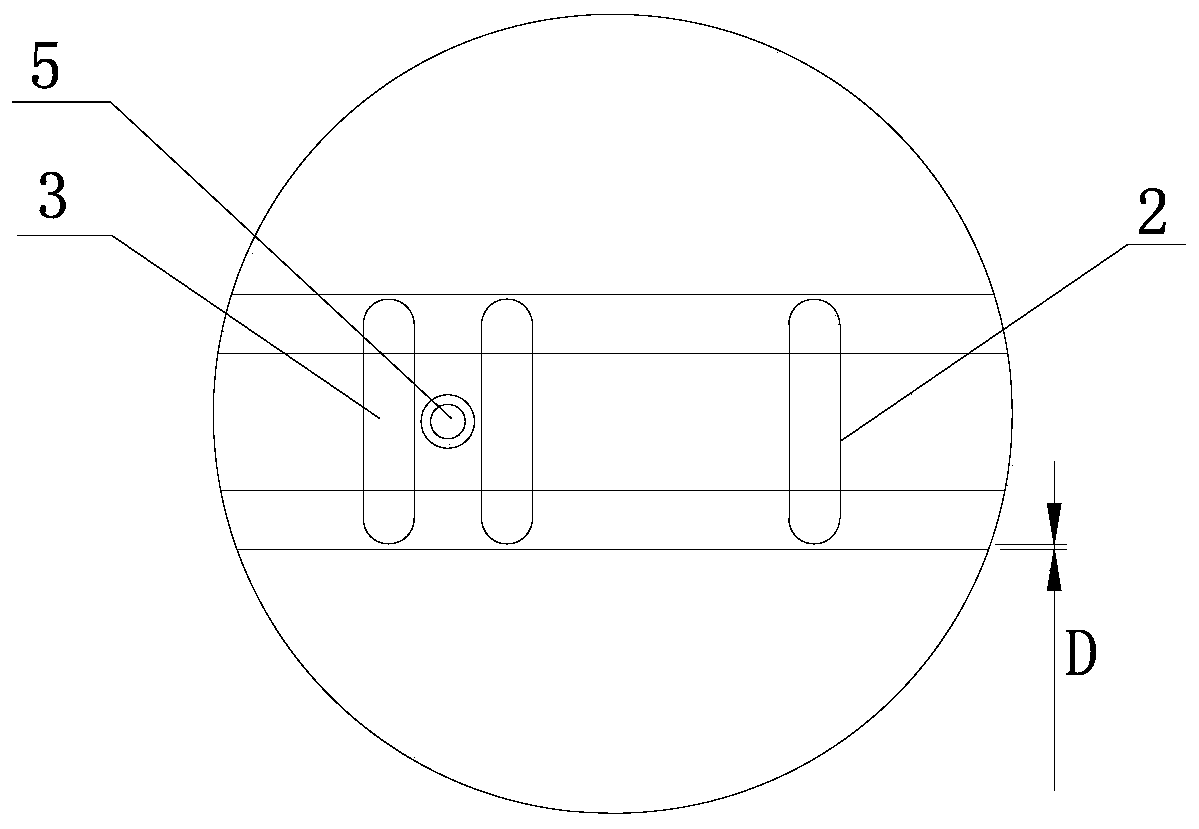

[0031] A magnetic pad suitable for a magnetic template proposed in this embodiment further defines the through hole 2 on the basis of the magnetic pad in Embodiment 1, that is, the thickness D of the hole wall of the through hole 2 is 1 ~2 mm. After opening a plurality of through holes 2 on the magnetizer 1, the magnetizer 1 is divided into a plurality of sub-magnetizers, and the adjacent two sub-magnetizers are connected by the walls of the through-holes 2, so that the plurality of sub-magnetizers are still As a whole, in order to ensure the connection strength between two adjacent sub-magnetic conductors, and to ensure that the area of the non-magnetic conductor 3 is large enough to isolate the magnetic interference of the adjacent magnetic poles as much as possible, the hole wall of the through hole 2 is determined through a large number of experiments. The thickness is 1-2 mm, such as 1.5 mm.

Embodiment 3

[0033] A magnetic permeable pad suitable for a magnetic force template proposed in this embodiment, on the basis of the magnetic permeable pad in embodiment one or embodiment two, defines the width B of the wide lower part 41 of the magnetic permeable pad 4 and the narrow upper part 42 The width A of the width A, the height C of the narrow upper part 42, that is, the width B of the wide lower part 41 of the magnetic pad 4 is consistent with the width of the magnetic pole 81 on the magnetic template 8, so that under the isolation of the non-magnetic body 3, the magnetic template 8 is guaranteed. All the lines of force of each magnetic pole 81 on the top diverge completely vertically upwards, and there will be no magnetic leakage phenomenon; The width of 1.6 millimeters, when grinder 9 carries out the side end surface processing of guide rail 7 like this, emery wheel 91 can not touch the narrow upper part 42 of magnetic conduction pad 4 and damage magnetic conduction pad 4; The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com