F-N-C composite material and preparation method and application thereof

A F-N-C, composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of low cycle stability of lithium-sulfur batteries, and achieve improved shuttle effect, specific capacity and cycle stability, and high porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

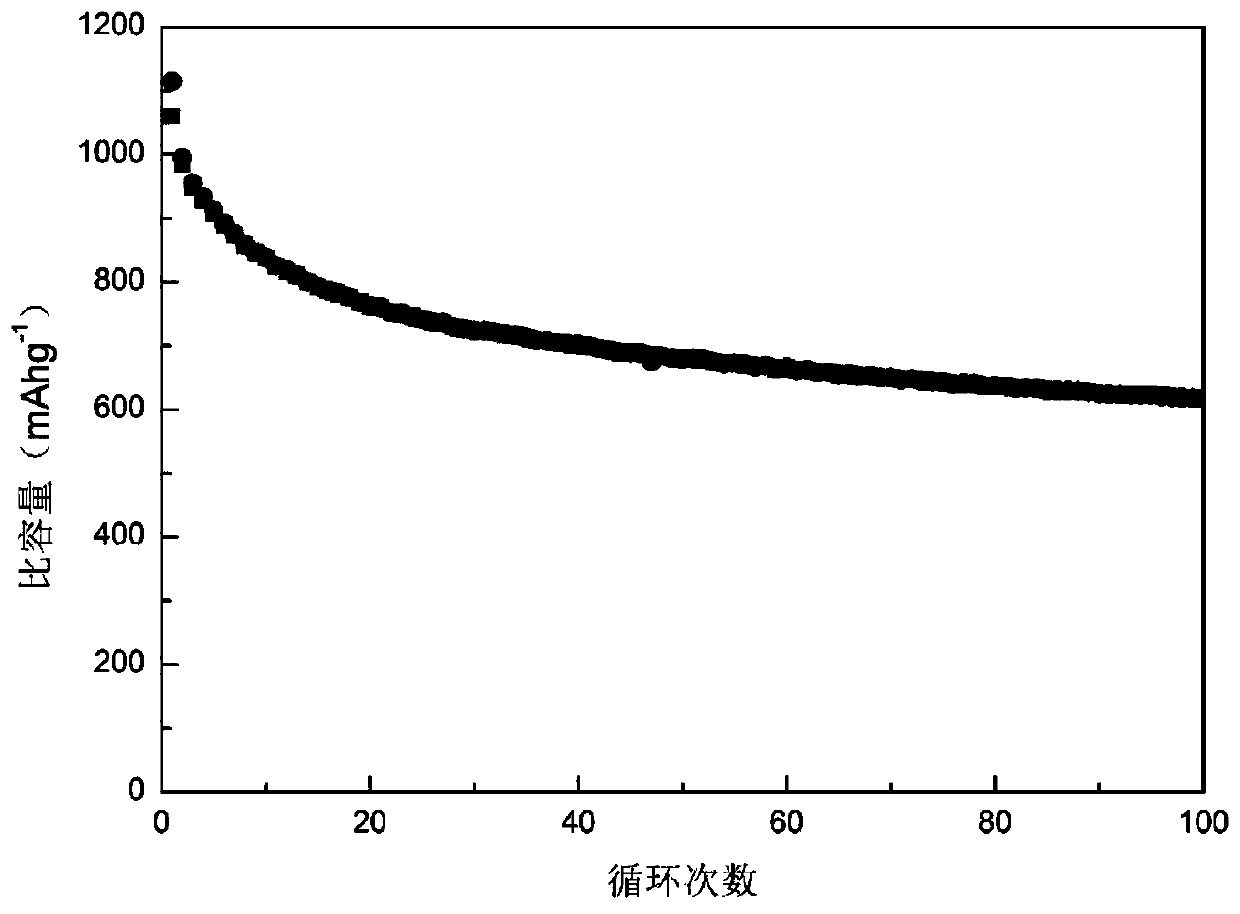

Embodiment 1

[0032] Dissolve 1.37g of zinc nitrate hexahydrate in 80mL of methanol to obtain solution A; dissolve 3.7g of 2-methylimidazole in 80mL of methanol to obtain solution B; mix solution A and solution B, stir at room temperature for 24h, wash and dry to obtain Metal-organic framework precursors. The metal-organic framework material precursor was placed in a high-temperature tube furnace, and under the protection of nitrogen, the temperature was raised to 800 °C at a rate of 5 °C / min and kept for 1 h to obtain a nitrogen-doped porous carbon material. Then the obtained nitrogen-doped porous carbon material is placed in a reactor, and an ammonium bifluoride solution is added, wherein the mass ratio of the nitrogen-doped porous carbon material to the ammonium bifluoride in the ammonium bifluoride solution is 1:1; the reactor is placed React in an oven at 150°C for 15 hours. After the reaction, wash with deionized water and dry to obtain a porous carbon material F-N-C composite materia...

Embodiment 2

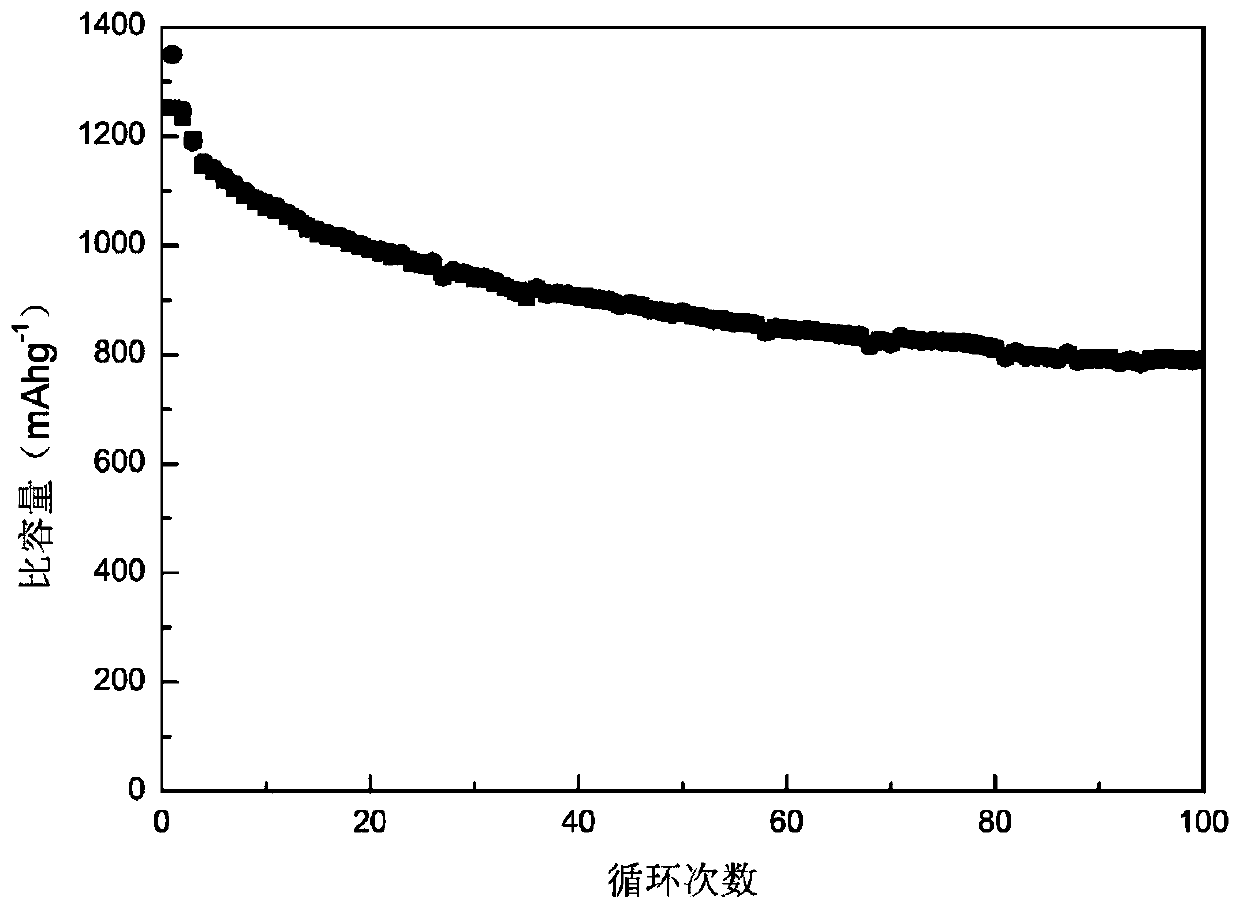

[0036]Dissolve 0.48g of zinc nitrate hexahydrate in 80mL of methanol to obtain solution A; dissolve 1.31g of 2-methylimidazole in 80mL of ethanol to obtain solution B; mix solution A and solution B, stir at room temperature for 24h, wash and dry to obtain Metal-organic framework precursors. The metal-organic framework material precursor was placed in a high-temperature tube furnace, and under the protection of nitrogen, the temperature was raised to 900°C at a rate of 5°C / min and kept for 2h to obtain a nitrogen-doped porous carbon material. Then the obtained nitrogen-doped porous carbon material is placed in a reactor, and an ammonium bifluoride solution is added, wherein the mass ratio of the nitrogen-doped porous carbon material to the ammonium bifluoride in the ammonium bifluoride solution is 0.5:2; React in an oven at 100°C for 16 hours. After the reaction, wash with deionized water and dry to obtain a porous carbon material F-N-C composite material co-doped with fluorine...

Embodiment 3

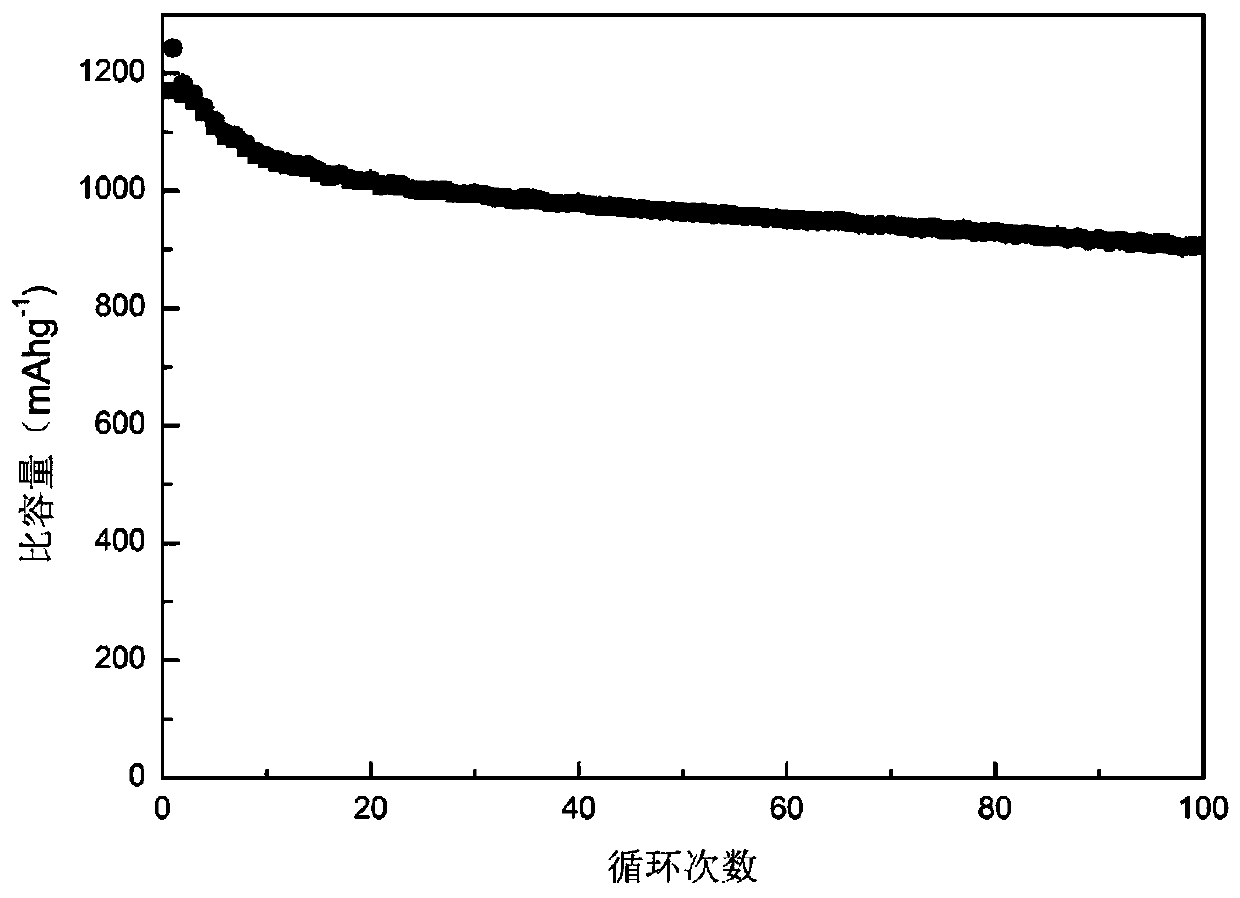

[0040] Dissolve 2.38g of zinc nitrate hexahydrate in 80mL of N,N-dimethylformamide to obtain solution A; dissolve 5.9g of 2-methylimidazole in 80mL of N,N-dimethylformamide to obtain solution B; Mix solution A and solution B, stir at room temperature for 24 hours, wash and dry to obtain a metal organic framework material precursor. The metal-organic framework material precursor was placed in a high-temperature tube furnace, and under the protection of nitrogen, the temperature was raised to 1000°C at a rate of 8°C / min and kept for 3h to obtain a nitrogen-doped porous carbon material. Then the obtained nitrogen-doped porous carbon material is placed in the reactor, and ammonium bifluoride solution is added, wherein the mass ratio of the nitrogen-doped porous carbon material to the ammonium bifluoride in the ammonium bifluoride solution is 1:2; the reactor is placed in React in an oven at 200°C for 12 hours, wash with deionized water after the reaction, and dry to obtain a porou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com