Grain drying device capable of uniformly transporting air

A drying device and grain technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of grain quality damage, uneven wind speed, uncontrollable grain density, etc., and achieve the effect of prolonging the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

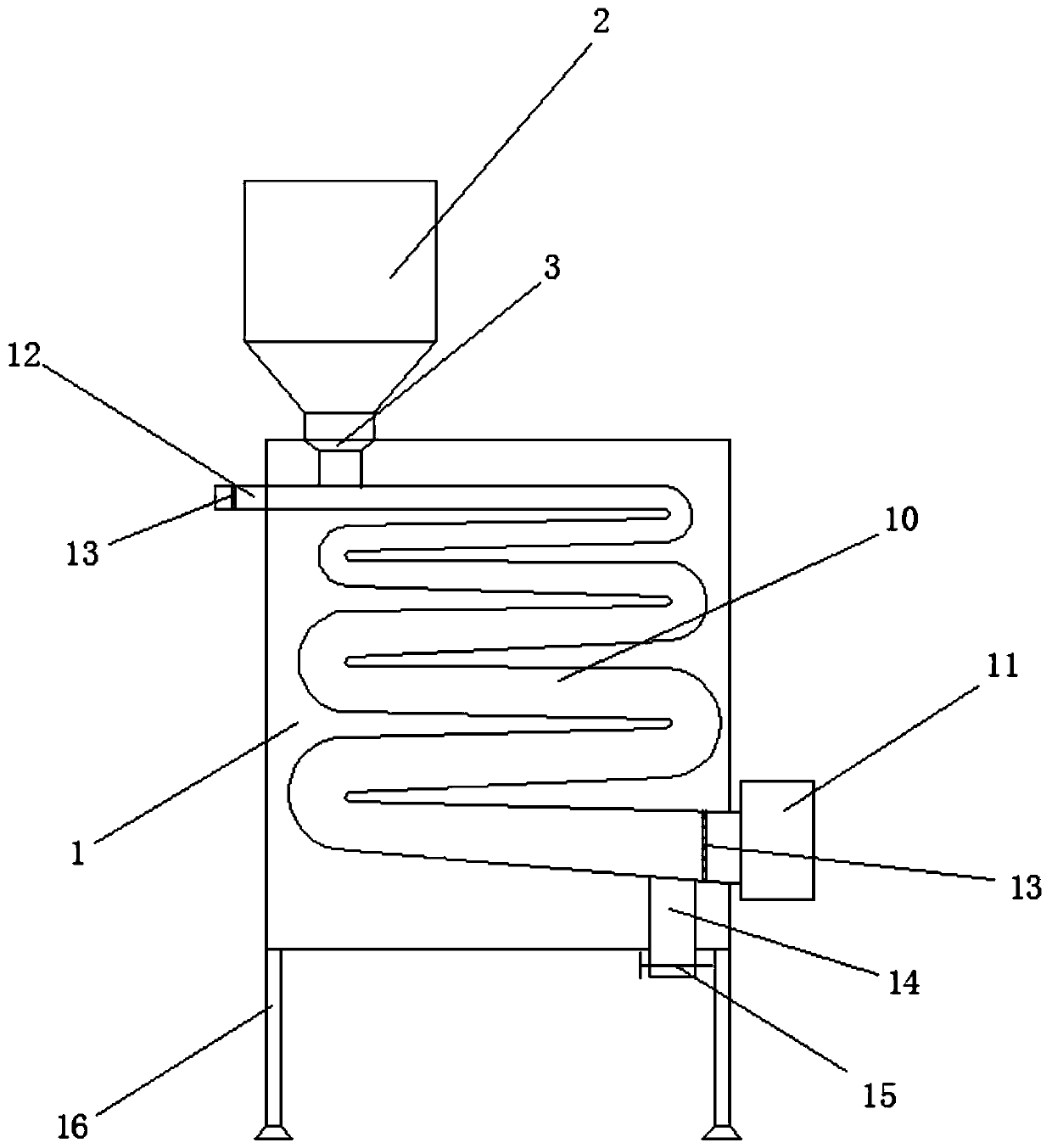

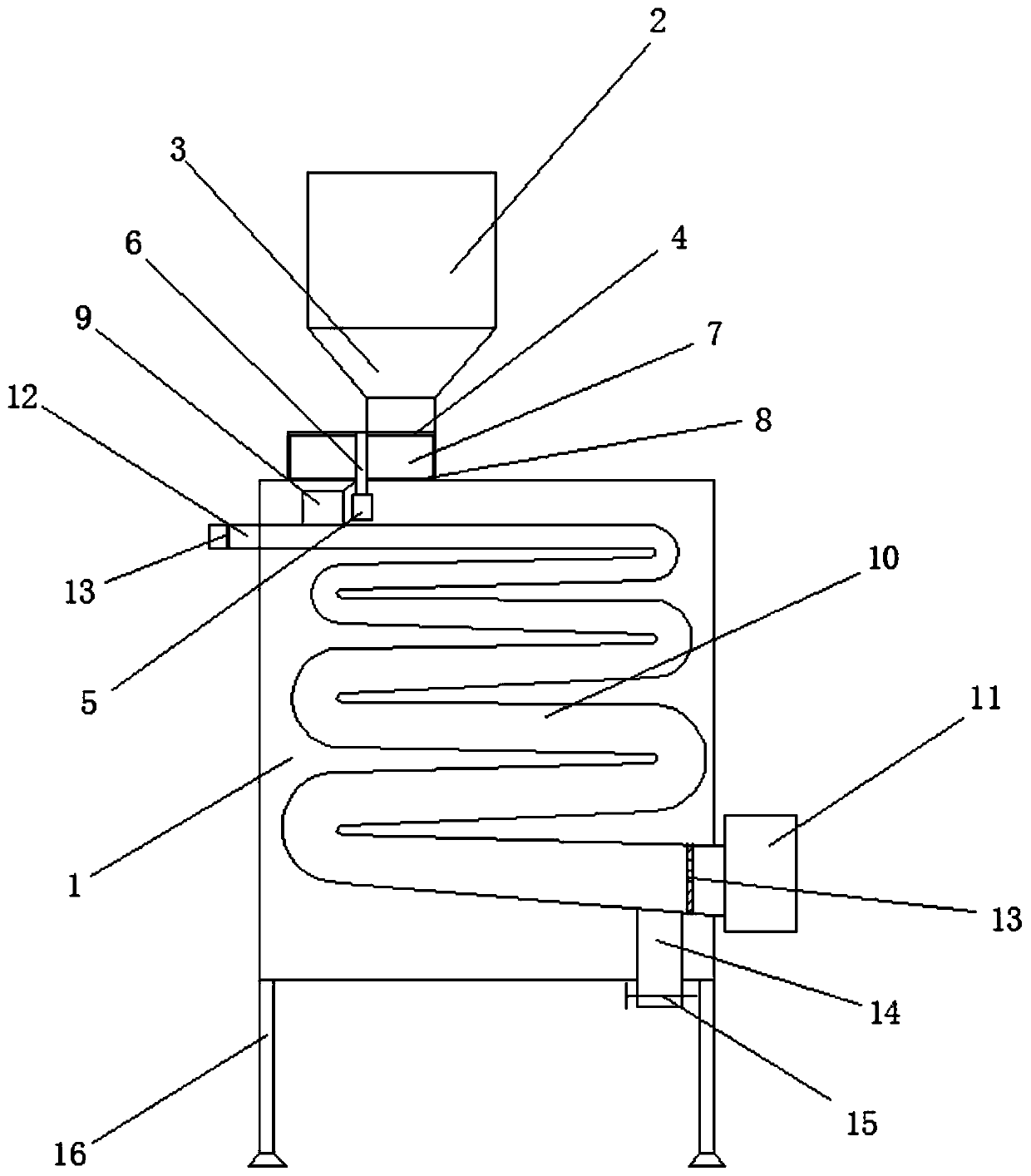

[0027] Embodiment 1: as Figure 1-2 As shown, a grain drying device with uniform air delivery includes: a drying bin 1, four sets of legs 16 are fixedly installed on the bottom of the drying bin 1 to enhance stability.

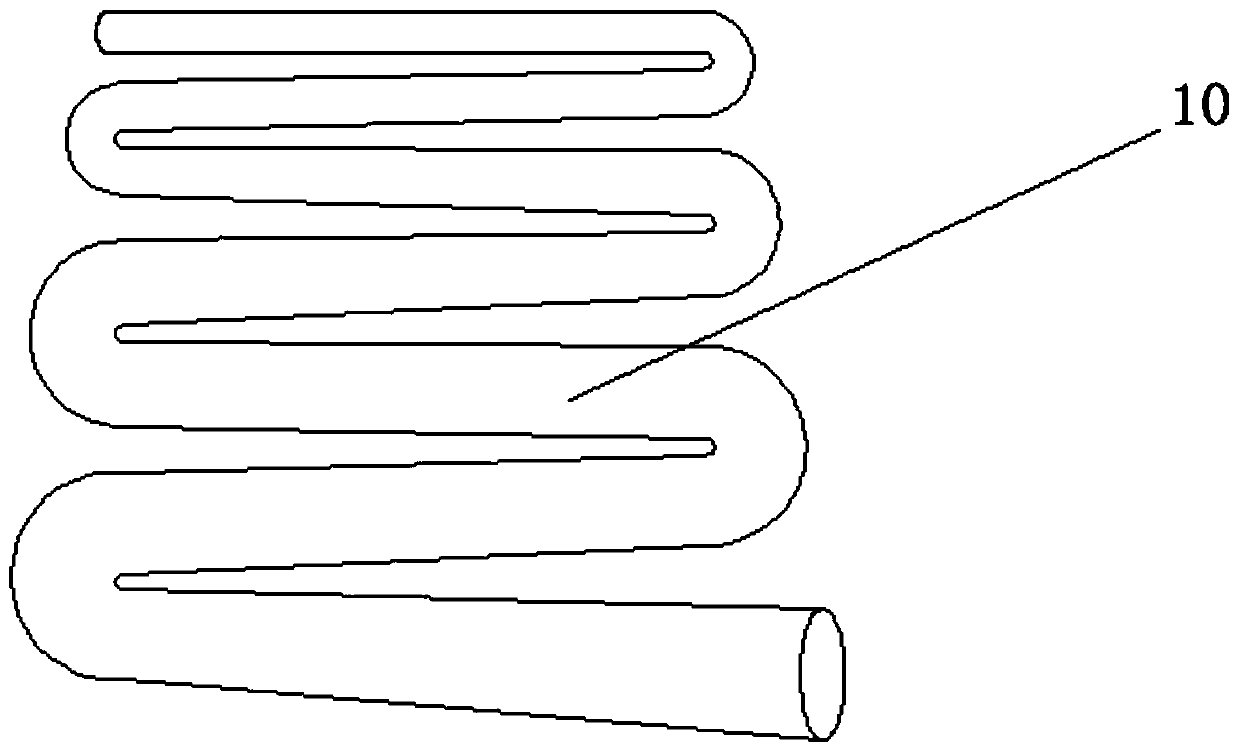

[0028] The inner cavity of the drying bin 1 is fixedly equipped with an S-shaped structure thermal circulation pipeline 10, the S-shaped structure thermal circulation pipeline can reduce the volume of the device and reduce the loss of heat in the drying bin, and the hot air is blown by the S-shaped structure The tail end of the heat circulation pipe transports hot air to the head end, and can prolong the time of grain in the drying bin.

[0029] The caliber from the head end to the tail end of the S-shaped structure thermal circulation pipeline 10 increases gradually, and the hot air blower transports the hot air from the tail end to the head end of the S-shaped structure heat circulation pipeline 10. With resistance, coupled with the influence of the gravita...

Embodiment 2

[0035] Embodiment 2: as Figure 1-4As shown, a grain drying device with uniform air delivery includes: a drying bin 1, four sets of legs 16 are fixedly installed on the bottom of the drying bin 1 to enhance stability.

[0036] The inner cavity of the drying bin 1 is fixedly equipped with an S-shaped structure thermal circulation pipeline 10, the S-shaped structure thermal circulation pipeline can reduce the volume of the device and reduce the loss of heat in the drying bin, and the hot air is blown by the S-shaped structure The tail end of the heat circulation pipe transports hot air to the head end, and can prolong the time of grain in the drying bin.

[0037] The caliber from the head end to the tail end of the S-shaped structure thermal circulation pipeline 10 increases gradually, and the hot air blower transports the hot air from the tail end to the head end of the S-shaped structure heat circulation pipeline 10. With resistance, coupled with the influence of the gravitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com