A single-side glass reinforcement-reinforcement cage structure for the ground connection wall of the shield tunnel

A ground-connected wall and reinforcement cage technology, which is applied to structural elements, underwater structures, and infrastructure engineering, can solve the problems of glass fiber reinforcement cages that cannot be hoisted, long hoisting time, and tank wall collapse, etc., to reduce engineering costs. Quantity, save hoisting time, ensure the effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

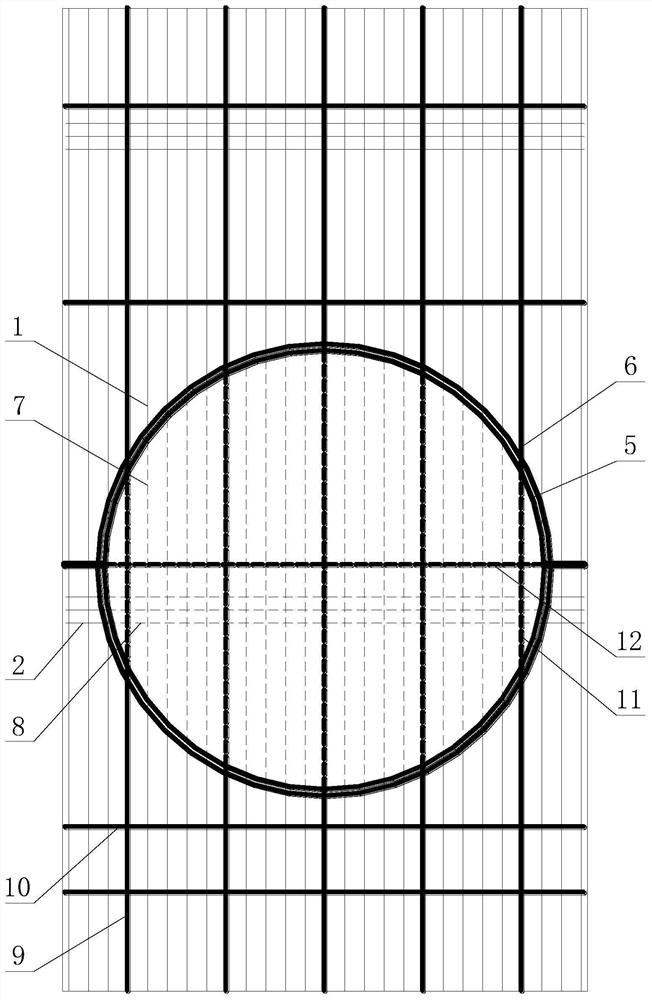

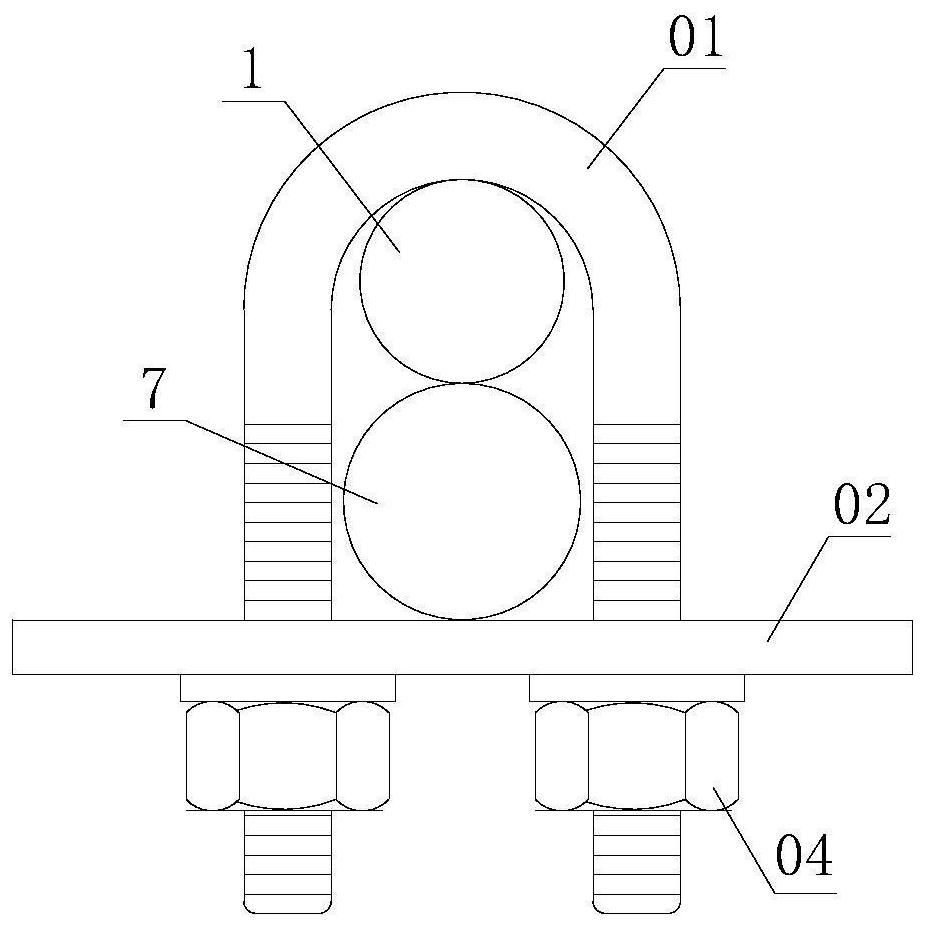

[0028] see Figure 1 to Figure 7 .

[0029] The invention is used for the single-side glass reinforcement-reinforcement cage structure of the ground connection wall of the shield tunnel door, including the ground connection wall reinforcement cage. Side vertical steel bars 1 and a plurality of soil-facing horizontal steel bars 2 arranged in the vertical direction, the back soil side of the ground connection wall reinforcement cage is closely connected with a door steel ring 5, and the ground connection wall reinforcement cage A circular steel bar truss 6 arranged coaxially with the door steel ring 5 is connected between the soil facing side and the back soil side, and the circular steel bar truss 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com