ZnO resistor disc and preparation method thereof

A technology of zinc oxide resistors and resistors, which is applied in the field of surge arrester piezoresistors, can solve the problem that the key indicators of GIS arrester safety, reliability, flow capacity, potential gradient impact resistance, and aging performance cannot be well matched. and other problems, to achieve the effect of simple preparation process and high technical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

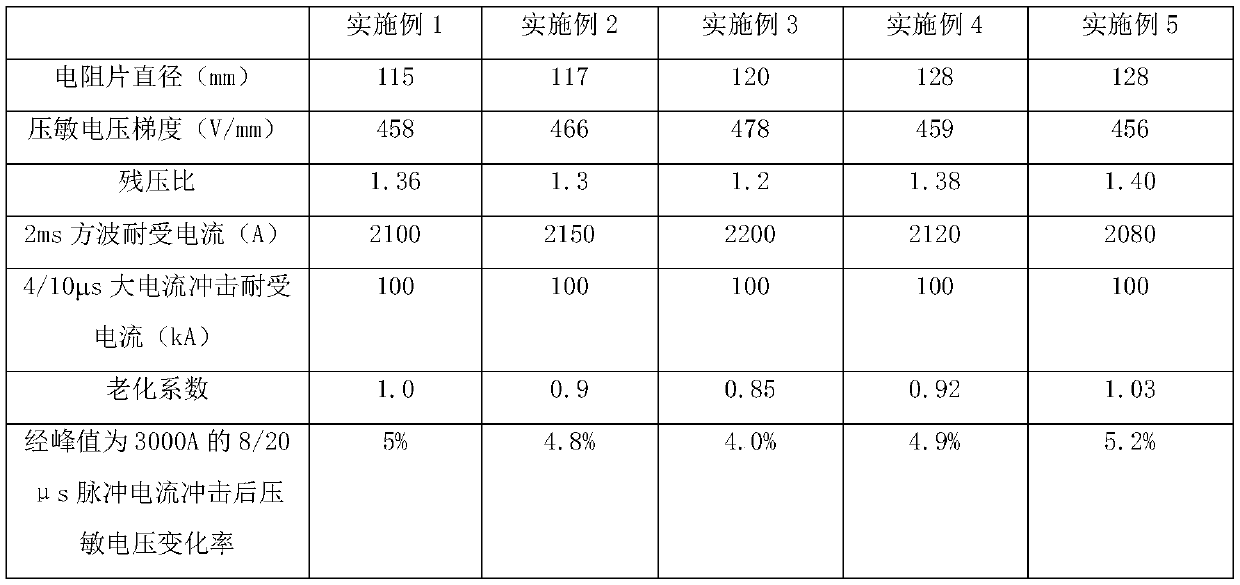

Examples

Embodiment 1

[0031] The preparation process of the varistor sheet for the zinc oxide arrester of this example comprises the following steps:

[0032] 1) Ingredients: prepared according to the mass percentage of raw materials, the specific formula is as follows: ZnO: 93%, Bi 2 o 3 : 2.5%, Co 3 o 4 : 0.1%, NiO: 0.2%, MnO: 0.2%, Sb 2 o 3 : 3.0%, SiO 2 : 0.3%, Er 2 o 3 : 0.2%, Ag 2 O: 0.5%.

[0033] 2) Ball milling and mixing: put the above-mentioned prepared raw materials into a nylon ball mill tank, add absolute ethanol as a dispersant according to 0.9 times the weight of the raw materials, and use zirconia balls as a ball milling medium, and use a planetary ball mill for ball milling. The ball milling speed is 350r / min, and adopts the combination of forward and reverse, the forward and reverse interval time is 30min, and the ball milling time is 6h;

[0034] 3) Drying: Put the slurry mixed by the ball mill in a clean enamel tray, and then put the tray in an electric constant tempe...

Embodiment 2

[0043] The preparation process of the varistor sheet for the zinc oxide arrester of this example comprises the following steps:

[0044] 1) Ingredients: prepared according to the mass percentage of raw materials, the specific formula is as follows: ZnO: 92%, Bi 2 o 3 : 3.0%, Co 3 o 4 : 0.2%, NiO: 0.4%, MnO: 0.3%, Sb 2 o 3 : 3.0%, SiO 2 : 0.3%, Er 2 o 3 : 0.2%, Ag 2 O: 0.6%.

[0045] 2) Ball milling and mixing: put the above-mentioned prepared raw materials into a nylon ball mill tank, add absolute ethanol as a dispersant according to 0.9 times the weight of the raw materials, and use zirconia balls as a ball milling medium, and use a planetary ball mill for ball milling. The ball milling speed is 350r / min, and adopts the combination of forward and reverse, the forward and reverse interval time is 30min, and the ball milling time is 8h;

[0046] 3) Drying: Put the slurry mixed by the ball mill in a clean enamel tray, and then put the tray in an electric constant tempe...

Embodiment 3

[0055] The preparation process of the varistor sheet for the zinc oxide arrester of this example comprises the following steps:

[0056] 1) Ingredients: prepared according to the mass percentage of raw materials, the specific formula is as follows: ZnO: 90%, Bi 2 o 3 : 2.0%, Co 3 o 4 : 0.15%, NiO: 0.7%, MnO: 0.65%, Sb 2 o 3 : 5.5%, SiO 2 : 0.2%, Er 2 o 3 : 0.3%, Ag 2 O: 0.5%.

[0057] 2) Ball milling and mixing: put the above-mentioned prepared raw materials into a nylon ball milling tank, add absolute ethanol as a dispersant according to 1.0 times the weight of the raw materials, and use zirconia balls as a ball milling medium, and use a planetary ball mill for ball milling. 400r / min, and adopts the combination of forward and reverse, the forward and reverse interval time is 30min, and the ball milling time is 6h;

[0058] 3) Drying: Put the slurry mixed by the ball mill in a clean enamel tray, and then put the tray in an electric constant temperature blast dryer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com