Coil automatic packing equipment and method

An automatic packaging and coiling technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low efficiency and difficulty in ensuring packaging quality, and achieve the effects of ensuring personnel safety, reducing manpower consumption, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

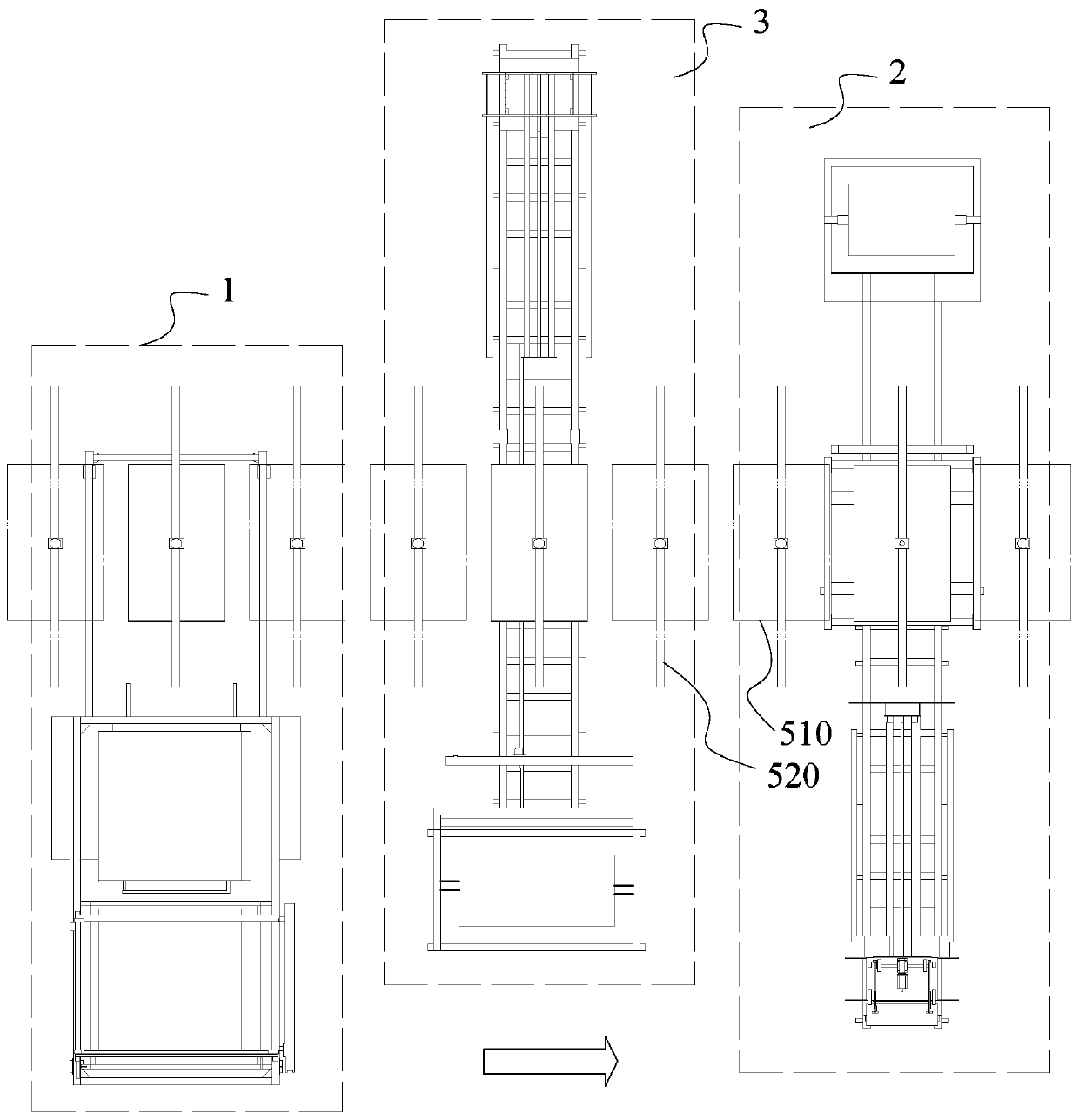

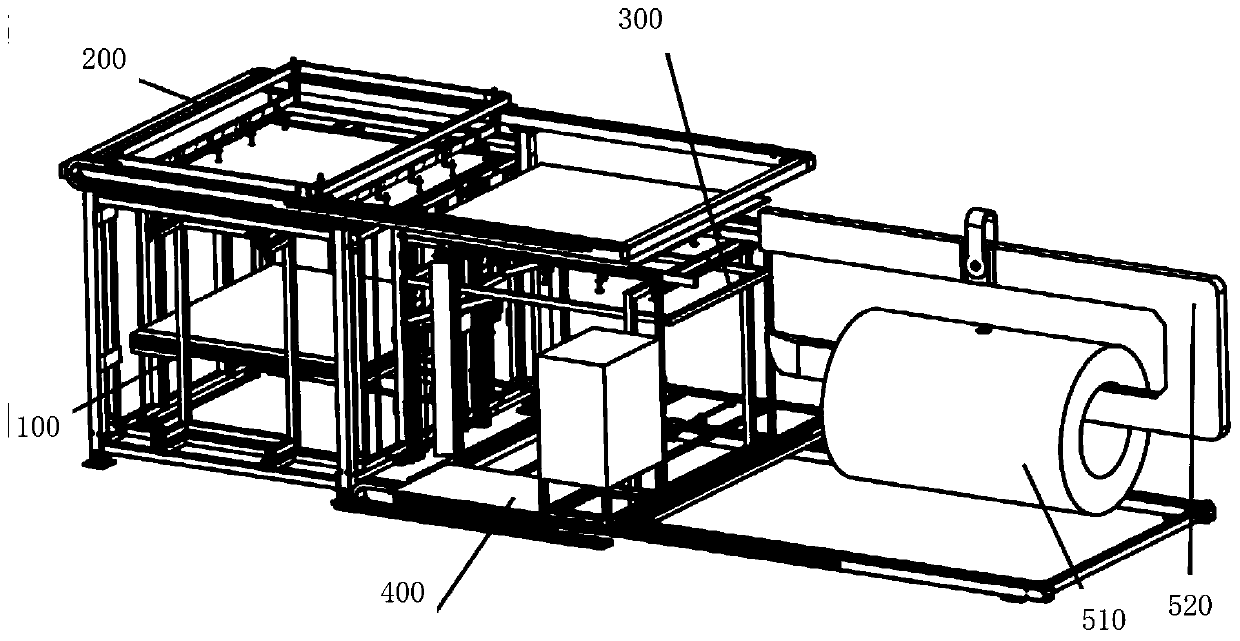

[0027] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1. The first aspect of the present invention provides a coil automatic packaging device, which combines figure 1 with figure 2 As shown, it includes a corrugated paper winding part 1, an inner bag covering part 2 and an outer bag covering part 3. The corrugated paper winding part 1 is installed at the first packaging process position, and the inner bag covering part 2 and the outer bag covering part 3 are respectively installed The positions of the second packaging process position and the third packaging process position are interchangeable; the arrangement positions of the three process positions are adapted to the circulation direction of the coil 510;

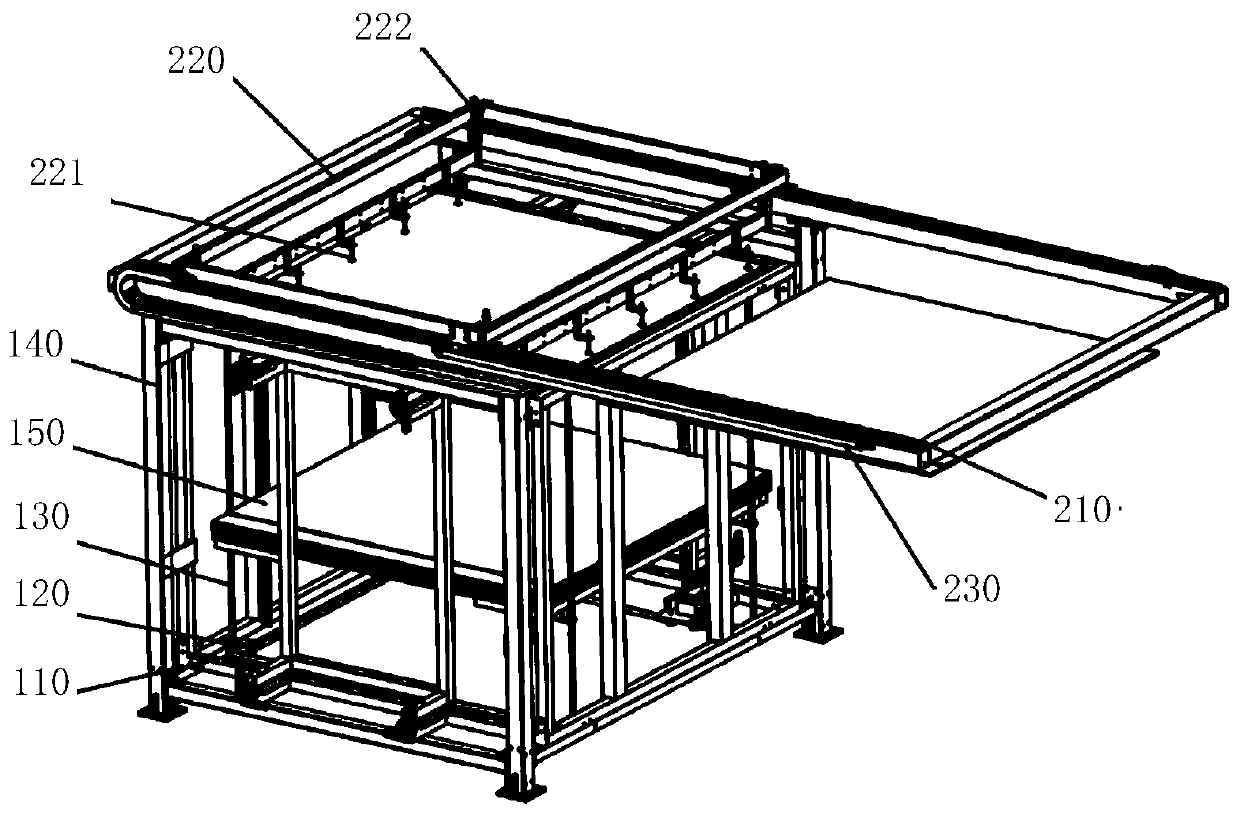

[0028] The corrugated paper winding unit 1 includes a buffer rack 100, a transfer unit 200, a discharge unit 300 and a binding unit 400. The buffer rack 100 is used to store folded corrugated paper; the transfer unit 200 is used to absorb from the buffer rack 100 A s...

specific Embodiment approach 2

[0077] Specific Embodiment 2. Another aspect of the present invention also provides a method for automatic packaging of coils, which is realized based on the automatic packaging equipment for coils, combined with Figure 1 to Figure 14 As shown, it includes: coiled corrugated paper winding method: the transmission unit 200 absorbs the corrugated paper from the buffer rack 100 and transmits it to the discharge unit 300; the transmission unit 200 cooperates with the discharge unit 300 to open the folded corrugated paper into a door shape; Then the corrugated paper is taken away from the discharging unit 300 by the binding unit 400, and the corrugated paper is transferred to the corresponding position of the coil through the opening of the C-shaped hook and wrapped on the coil, and then the corrugated paper is bound and fixed; the packaging method also includes Coil inner bag bagging method and coil outer bag bagging method, the execution order of the two can be interchanged;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com