Pure plant preservative composition as well as preparation method thereof and application thereof to facial masks

A preservative and composition technology, applied in the field of daily chemicals, can solve the problems of polyols that are prone to fever, complex components, allergies, etc., and achieve the effects of high skin safety, low content of impurity components, and high safety in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

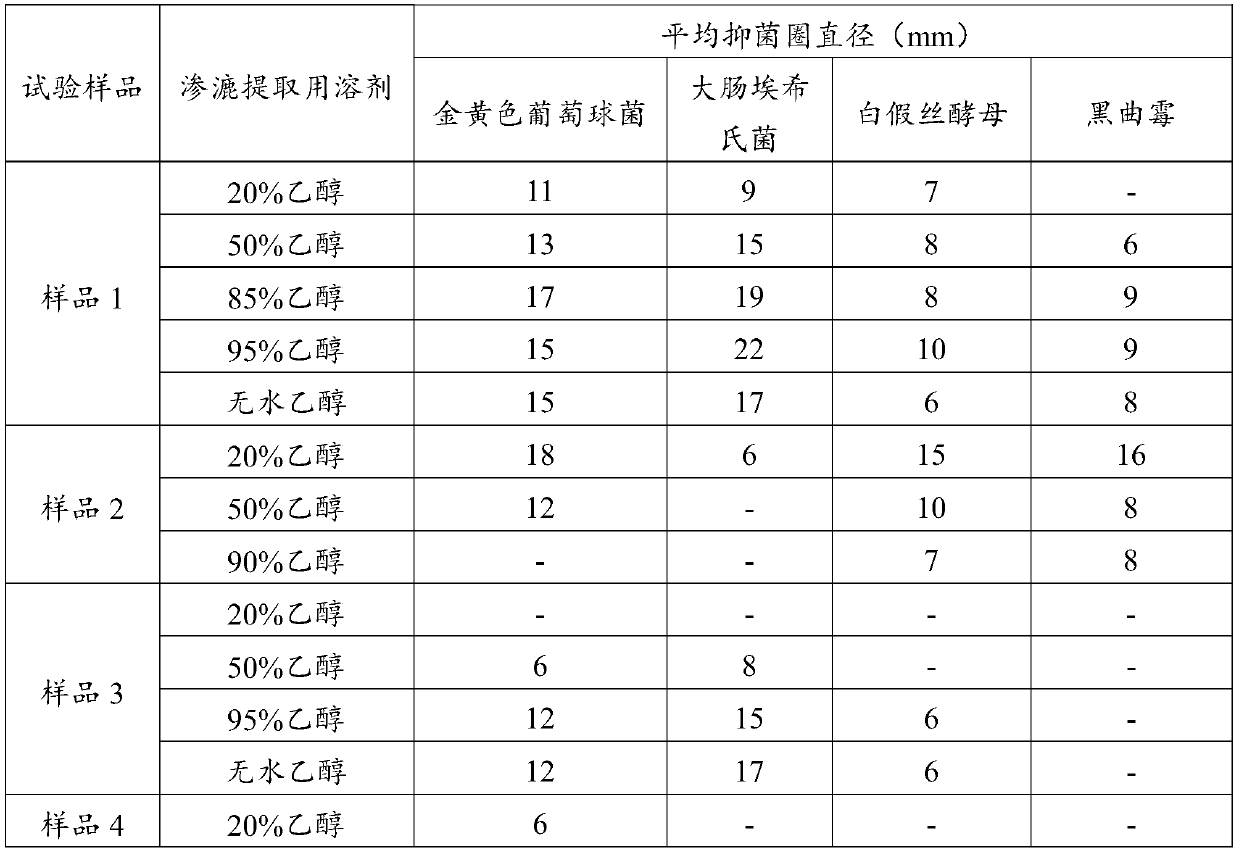

Examples

Embodiment 1

[0041] The present embodiment provides a kind of pure plant antiseptic composition, and raw material component comprises:

[0042] 10 parts by weight of Polygonum cuspidatum extract, 10 parts by weight of Zanthoxylum bungeanum extract, 10 parts by weight of chrysanthemum flower extract, 10 parts by weight of rosemary extract, 10 parts by weight of licorice extract, 2 parts by weight of tea leaf extract;

[0043] The Polygonum cuspidatum extract is extracted by the following method:

[0044] (1) Dried Polygonum cuspidatum for 3 hours at 50°C and crushed to obtain coarse powder of Polygonum cuspidatum with a particle size of 40 meshes; (2) Extracting the coarse powder of Polygonum cuspidatum with 90vol% ethanol by percolation, and extracting by percolation The percolation flow rate is 3ml / min·kg, and the percolation extraction is carried out until the weight of the percolation liquid is 9 times the weight of the medicinal material, and the ethanol percolation liquid is obtained;...

Embodiment 2

[0058] The present embodiment provides a kind of pure plant antiseptic composition, and raw material component comprises:

[0059] 12 parts by weight of knotweed extract, 12 parts by weight of Zanthoxylum bungeanum extract, 12 parts by weight of chrysanthemum flower extract, 8 parts by weight of rosemary extract, 8 parts by weight of licorice extract, and 3 parts by weight of tea leaf extract;

[0060] The Polygonum cuspidatum extract is extracted by the following method:

[0061] (1) Dried Polygonum cuspidatum for 3 hours at 50°C, and pulverized to obtain coarse powder of Polygonum cuspidatum with a particle size of 60 mesh; (2) Extracting the coarse powder of Polygonum cuspidatum with 90vol% ethanol by percolation, the percolation extracted The percolation flow rate is 3ml / min·kg, and the percolation extraction is carried out until the weight of the percolation liquid is 9 times the weight of the medicinal material, and the ethanol percolation liquid is obtained; (3) the eth...

Embodiment 3

[0075] The present embodiment provides a kind of pure plant antiseptic composition, and raw material component comprises:

[0076] 8 parts by weight of Polygonum cuspidatum extract, 8 parts by weight of Zanthoxylum bungeanum extract, 12 parts by weight of chrysanthemum flower extract, 12 parts by weight of rosemary extract, 12 parts by weight of licorice extract, 3 parts by weight of tea leaf extract;

[0077] The Polygonum cuspidatum extract is extracted by the following method:

[0078] (1) Dried Polygonum cuspidatum for 3 hours at 50°C, and pulverized to obtain coarse powder of Polygonum cuspidatum with a particle size of 80 meshes; (2) Extracting the coarse powder of Polygonum cuspidatum with 90vol% ethanol by percolation, and extracting by percolation The percolation flow rate is 3ml / min·kg, and the percolation extraction is carried out until the weight of the percolation liquid is 9 times the weight of the medicinal material, and the ethanol percolation liquid is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com