Split type hot blast stove

A hot blast stove, split-type technology, applied in the field of split-type hot blast stove, can solve the problems of large heat loss of secondary combustion furnace, large difference in flue gas temperature, insufficient combustion of biomass particles, etc., to achieve convenient flue gas temperature, heat The effect of small loss and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

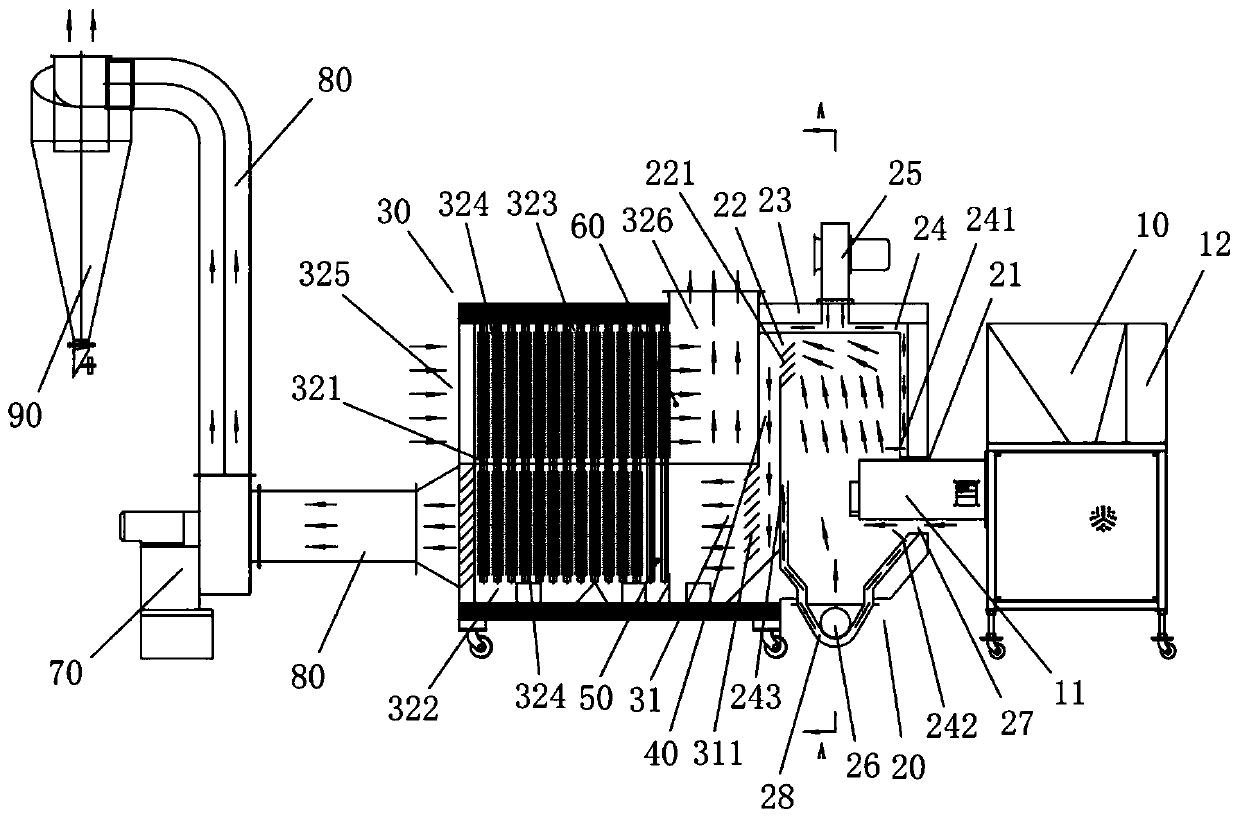

[0039] see Figure 1 to Figure 8 , a split-type hot blast stove according to an embodiment of the present invention, the split-type hot blast stove is mainly used to burn biomass particles, recover the heat of flue gas generated by combustion, and form clean hot air, which is used for materials (such as grain ) drying or hot air for industrial and domestic use.

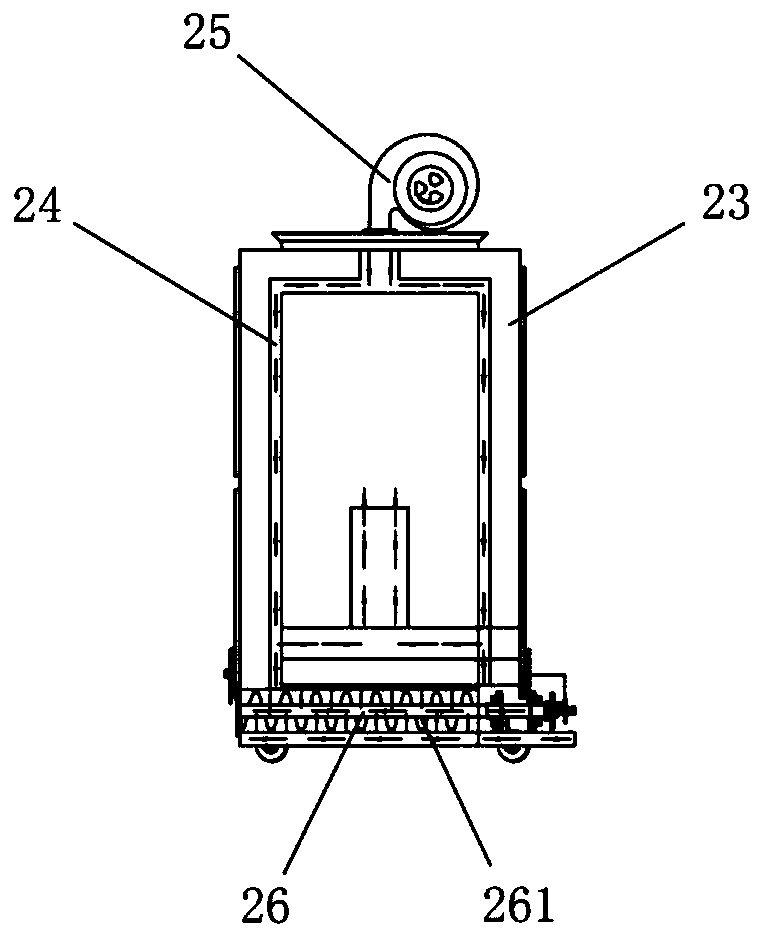

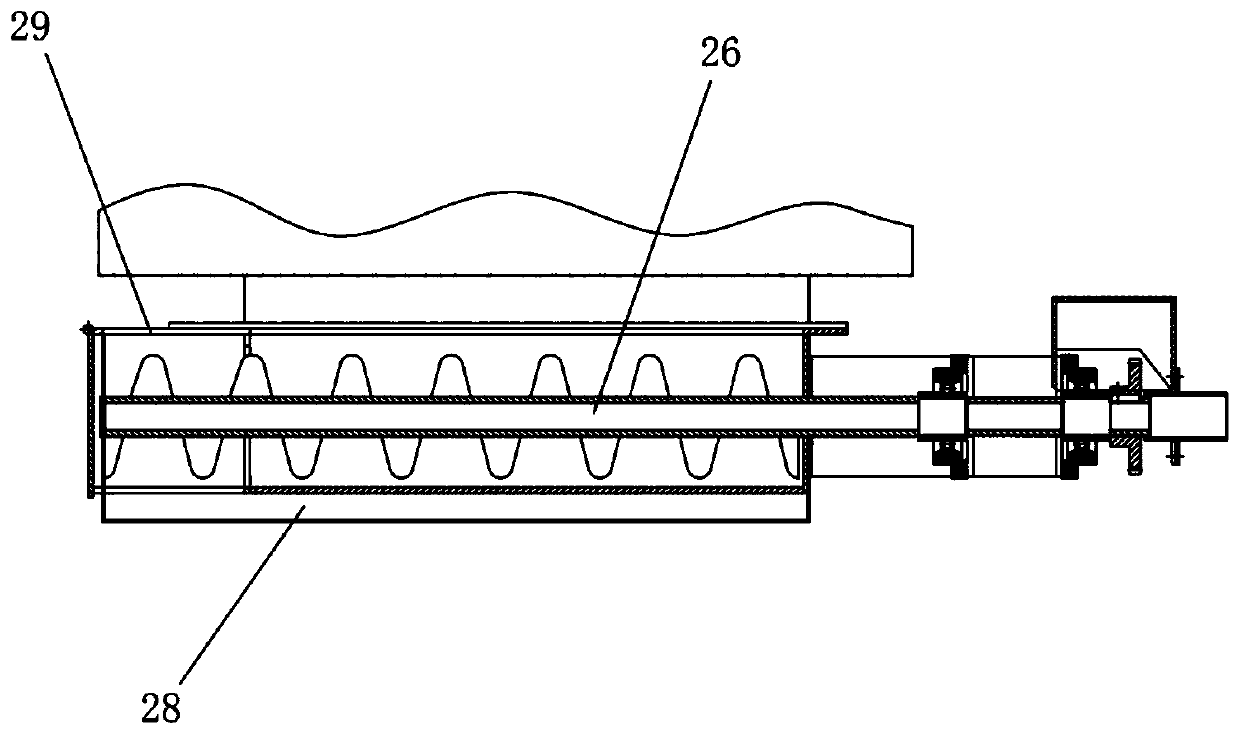

[0040] Depend on Figure 1 to Figure 8 It can be seen that the split hot blast stove mainly includes a burner 10 , a secondary combustion furnace 20 and a flue gas heat exchange device 30 . Wherein, the flame nozzle 11 of the burner 10 communicates with the flame receiving port 21 of the secondary combustion furnace 20 , and the flue gas outlet 22 of the secondary combustion furnace 20 communicates with the flue gas inlet 31 of the flue gas heat exchange device 30 . The furnace wall 23 of the secondary combustion furnace 20 is provided with an air intake interlayer 24, and a blower 25 is installed on the furnace wal...

Embodiment 2

[0054] Another embodiment of the split-type hot blast stove of the present invention, the main structure of the hot blast stove of this embodiment is the same as that of Embodiment 1, the main difference is that the structures of the flue gas heat exchange chamber 322 and the clean air heat exchange chamber 323 are different. see Figure 9 and Figure 10 , in this embodiment, in order to facilitate transportation and reduce the overall length of the equipment, two flue gas heat exchange chambers 322 of the split-type hot blast stove are set, and the two flue gas heat exchange chambers 322 are arranged side by side, and the two flue gas heat exchange chambers The heat chambers 322 are separated by a vertical flue gas partition 327, and the two flue gas heat exchange chambers 322 communicate with each other at the ends to form a U-shaped flue gas channel; there are also two clean air heat exchange chambers 323, Two clean air heat exchange chambers 323 are arranged side by side,...

Embodiment 3

[0057] Another embodiment of the split hot blast stove of the present invention, the main structure of the hot blast stove of this embodiment is the same as that of embodiment 1 or embodiment 2, compared with embodiment 1 and embodiment 2, the split hot blast stove of this embodiment The main difference is that the automatic thermostat electric control device is added.

[0058] see figure 1 , in order to regulate the flue gas temperature and clean hot air temperature more conveniently, the split type hot blast stove also includes an automatic temperature regulation electric control device, which includes a flue gas temperature measurement probe 50, a clean air temperature measurement probe 60. The tail smoke temperature measuring probe (not shown in the figure) and the temperature adjustment controller 12. The flue gas temperature measuring probe 50 is installed near the flue gas inlet 31 of the flue gas heat exchange chamber 322 to detect the temperature of the flue gas ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com