Monitoring and analyzing integrated detection device for steel-making wastewater

A technology for steelmaking wastewater and testing equipment, which is applied in water/sewage treatment equipment, analytical materials, metallurgical wastewater treatment, etc., can solve the problem of high processing cost, achieve the effect of improving work efficiency and ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

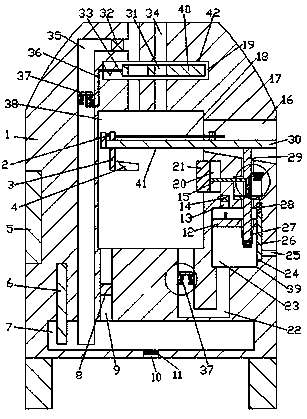

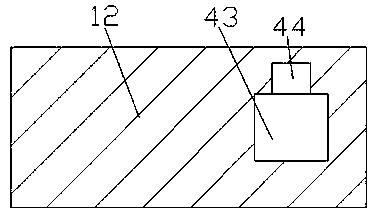

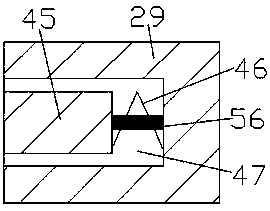

[0024] Combine below Figure 1-5 The present invention will be described in detail, in which, for the convenience of description, the following directions are specified as follows: figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

[0025] Attached Figure 1-5 The structure diagram of a detection device integrating monitoring and analysis of steelmaking wastewater mainly includes a processor 1, a detection circulation mechanism 42 in the processor 1, two one-way valve mechanisms 37, an air supply mechanism 39, and a salvage Agency 41.

[0026] The processor 1 is provided with a reaction chamber 38 and a feed pipe 34 connecting the external space and the reaction chamber 38, and a circulation pipe 35 connecting the external space and the reaction chamber 38 is provided in the left end wall of the reaction chamber 38, Add waste water and anionic surfactant into the reaction chamber 38. At this time, the air supply mechanism 39 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com