Packaging box of air radiator and method thereof

A packaging method and radiator technology, applied in the field of transportation, can solve the problems of insufficient strength, difficult for buyers to disassemble, and large damage to printer equipment, and achieve the effect of increasing the ability to withstand bending, reducing cost and quality, and fast packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

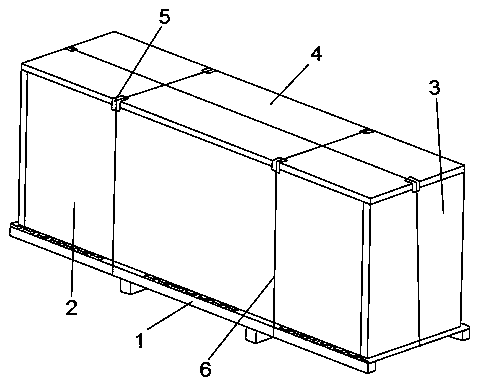

[0031] refer to Figure 1~5 , a packaging method for an air radiator, comprising the following steps:

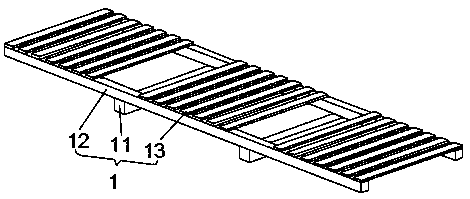

[0032] Step A. Place the supporting board 1 horizontally on the ground; spread the air bubble film on the supporting board 1 and fix it with screws; install four corner protectors on the four corners of the supporting board 1 while installing the air bubble film;

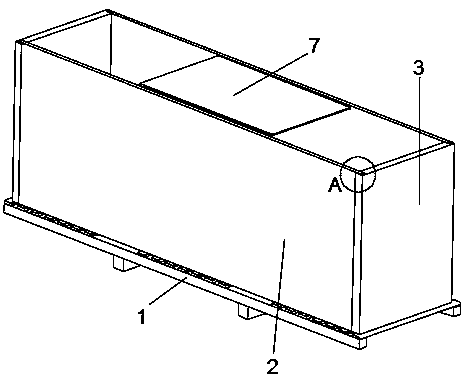

[0033] Step B. Lift the air radiator onto the supporting plate 1 and fix it with bolts;

[0034] Step C. On the supporting plate 1, snap the two long side plates 2 into the slots 31 of the two short side plates 3; the inner walls of the long side plates 2 are pasted with pearl cotton 8, and the pearl cotton 8 is in contact with the air radiator ;

[0035] Step D, put the support plate 7 on the top of the air radiator, and cover the cover plate 4 at the same time to form a box as a whole;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com