Transparent border touch screen and preparation method thereof

A touch screen, transparent technology, applied in the direction of equipment with touch panel/sensor/detector, branch office equipment, telephone structure, etc., can solve the problem of high cost of materials, inability of wiring to enter the touch screen, touch screen Problems such as screen-to-body ratio cannot be realized, and achieve the effect of reducing process steps, reducing manufacturing costs, and increasing screen-to-body ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

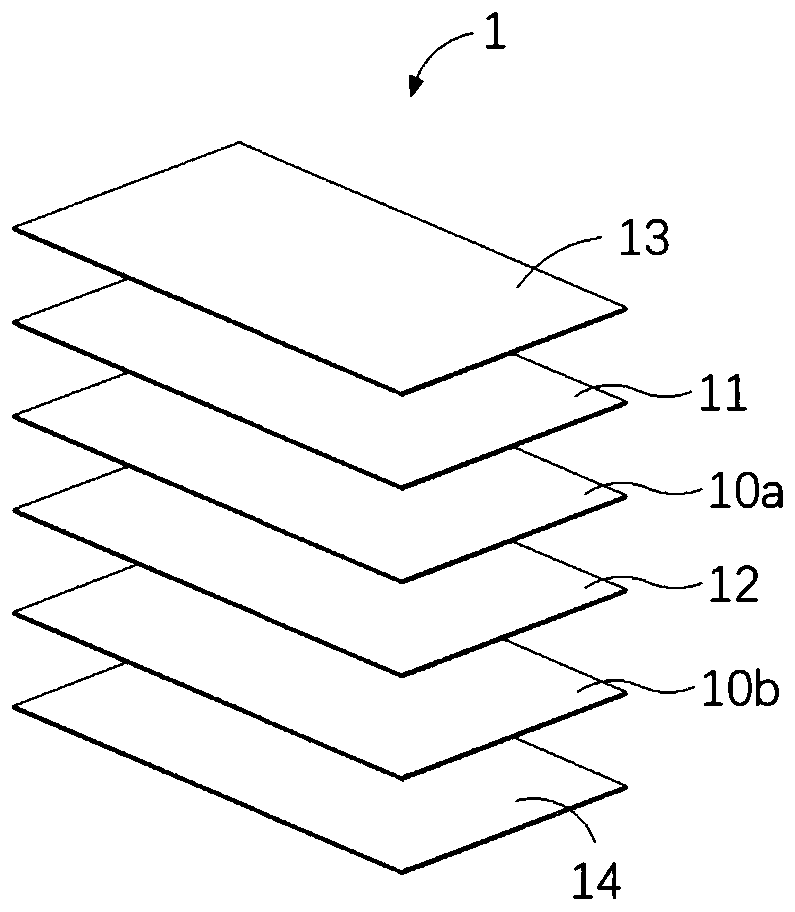

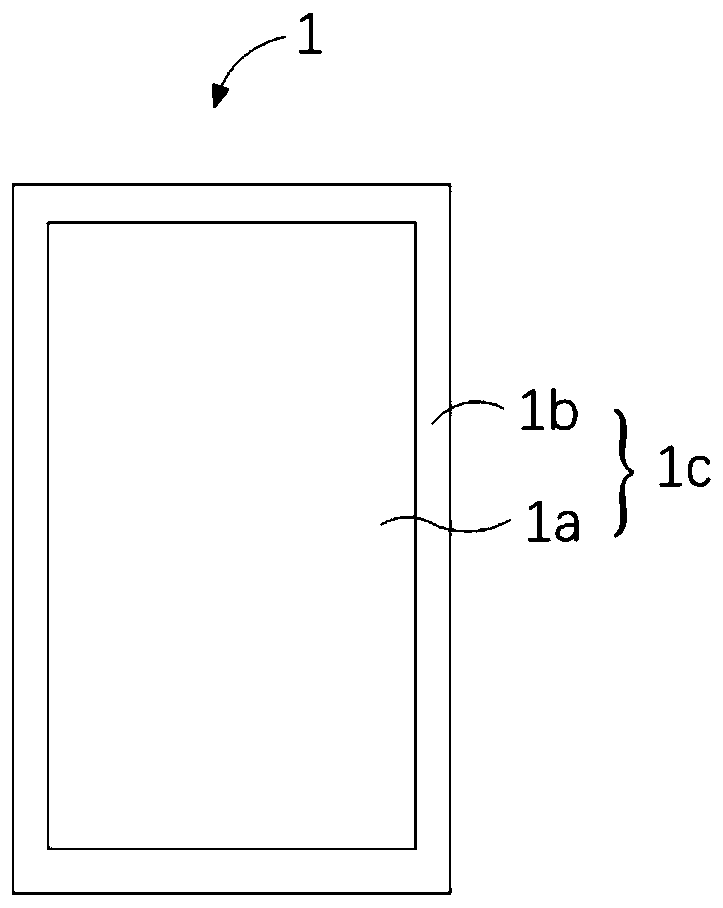

[0071] Please also refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention provides a borderless touch screen, the touch screen 1 includes a polymer film 10, and the polymer film 10 is pasted with a first transparent touch layer 11 and a second transparent touch layer 12 , the second transparent touch layer 12 and the first transparent touch layer 11 are attached to different surfaces of the polymer film 10, and both the first transparent touch layer 11 and the second transparent touch layer 12 include a touch area 1a and The wiring area 1b, the touch area 1a is provided with a touch graphic circuit (not shown), the touch graphic line is provided with a receiving end or a transmitting end, and the wiring area 1b is set around the outer periphery of the touch area 1a, The wiring area 1b is provided with a touch output line (not shown) connected to the receiving end and the transmitting end. The material of the touch output line, the receiving electrode and the em...

Embodiment 2

[0106] Such as Figure 5 and Figure 6 As shown, the present invention provides a method for manufacturing a touch screen based on the first embodiment above, and the method includes the following steps:

[0107] 201. Provide polymer films, cover plates and display screens.

[0108] In this embodiment, the number of layers of the polymer film is preferably one layer, and the material of the polymer film can be polyimides, polyethylene terephthalates, polyacrylics, polyurethanes, rings, etc. Any of olefin polymers and the like.

[0109] 202. Form a first transparent touch layer and a second transparent touch layer on the upper surface and the lower surface of the polymer film respectively, specifically including the following steps:

[0110] 202a. Coating a transparent multi-component alloy on the upper surface and the lower surface of the polymer film to form a first transparent conductive layer and a second transparent conductive layer.

[0111] 202b. Spread a photosensit...

Embodiment 3

[0123] see Figure 7 and see again Figure 5 , Embodiment 3 of the present invention provides a kind of preparation method, the difference between the preparation method of Embodiment 3 of the present invention and the preparation method of Embodiment 2 is:

[0124] 303. Form a first transparent touch layer and a second transparent touch layer on the upper surface and the lower surface of the polymer film respectively, specifically including the following steps:

[0125] 302a, respectively coating a transparent multi-component alloy on the upper surface and the lower surface of the polymer film to form a first transparent conductive layer and a second transparent conductive layer;

[0126] 302b. Perform laser etching on the surfaces of the first transparent conductive layer and the second transparent conductive layer to form the first transparent touch layer and the second transparent touch layer.

[0127] Specifically, the laser etching machine is controlled by computer sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com