Preparation method of cylinder photosensitive resist

A technology of photosensitive glue and rotary screen, applied in the field of photosensitive glue, can solve the problems such as the consumption of rotary screen, seriousness, difficult to peel off the resin, etc., and achieve the effect of saving cost, reducing the number of hydroxyl groups, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] refer to figure 1 , the preparation method of a kind of rotary screen photosensitive adhesive disclosed by the present invention, comprises the following steps:

[0062] S1: Coating a layer of isolation layer on the surface of the cylinder;

[0063] Step (1): Grinding filler raw materials into powder in proportion, and mixing evenly;

[0064] Step (2): coating a layer of adhesive on the surface of the cylinder;

[0065] Step (3): coating the filler powder in step (1) on the surface of the adhesive to form a filler layer, and the thickness of the filler layer is controlled at 2mm;

[0066] Step (4): Press the filler layer on the cylinder until the adhesive solidifies;

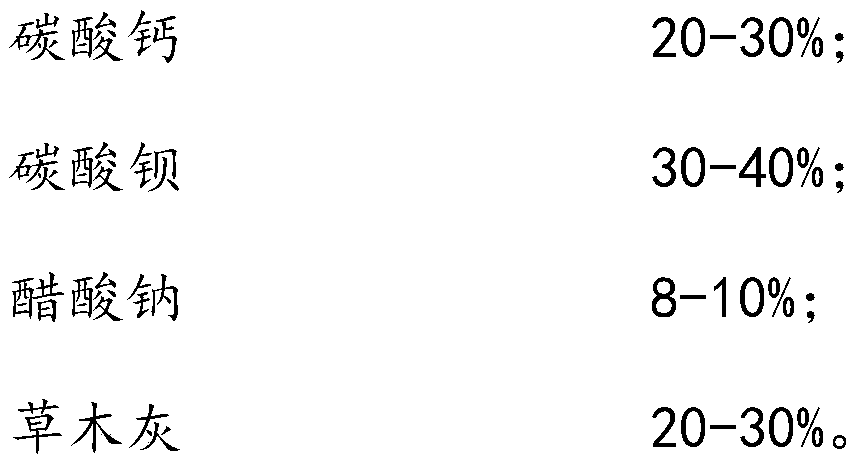

[0067] Wherein, filler comprises the component of following percentage by weight:

[0068]

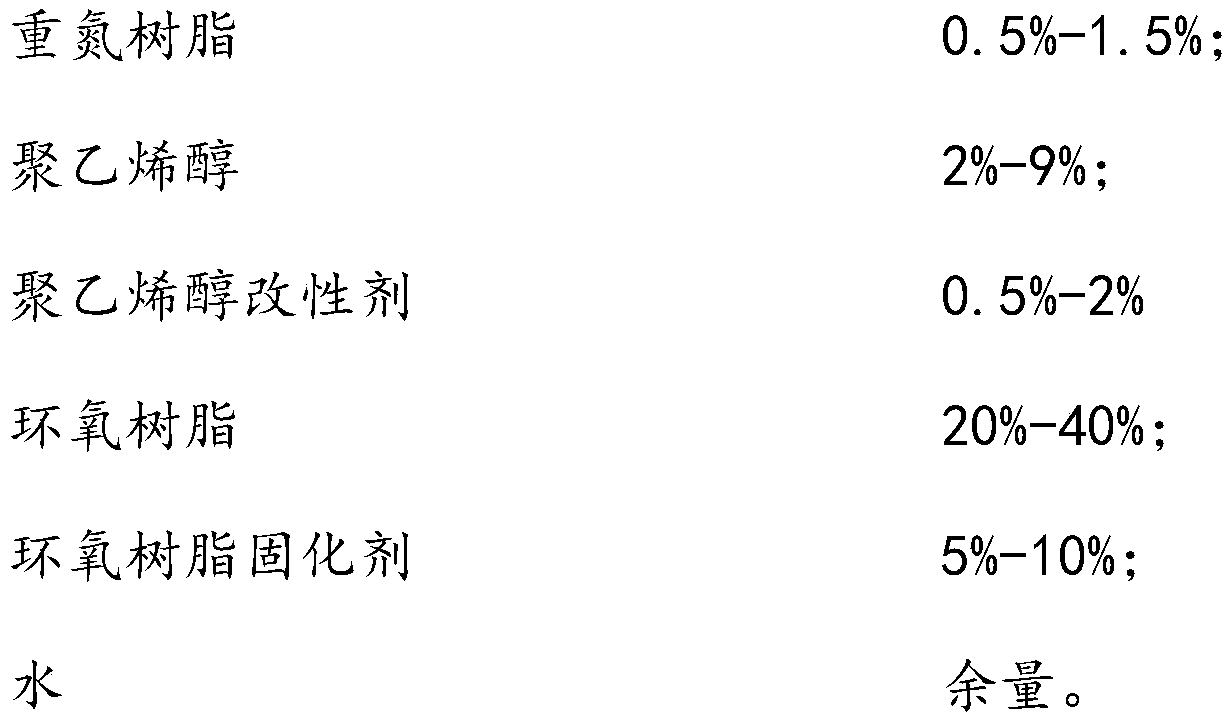

[0069] S2: step (1) prepare photosensitive glue raw material, its each component weight percent is as follows:

[0070]

[0071] Wherein, epoxy resin curing agent comprises the component of following we...

Embodiment 1

[0095] The difference between Examples 11-14 and Example 1 is that each component in the photosensitive adhesive raw material is calculated in the following table by weight percentage.

[0096]

[0097]

[0098] The difference between Examples 15-18 and Example 1 is that each component in the epoxy resin curing agent is calculated in the following table by weight percentage.

[0099]

[0100] The difference between Examples 19-22 and Example 1 is that each component in the polyvinyl alcohol modifier is listed in the following table by weight percentage.

[0101]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com