Supersonic laser deposition spray gun, laser deposition device and laser deposition method

A supersonic laser and spray gun technology, which is applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problems of high cost, limitation of large-scale industrial application, material utilization rate, and low laser energy utilization rate. , to achieve the effect of improving the utilization rate and, high bonding firmness and surface smoothness, maintaining the original components and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

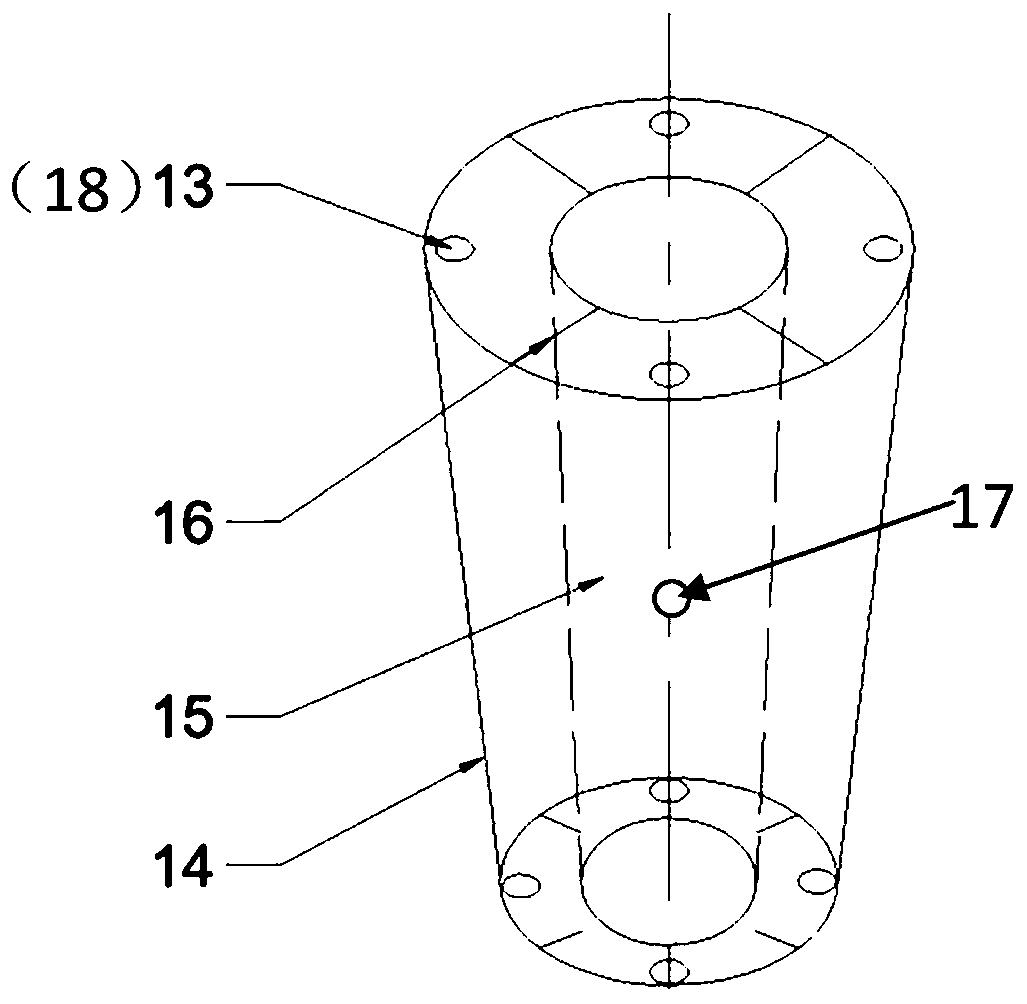

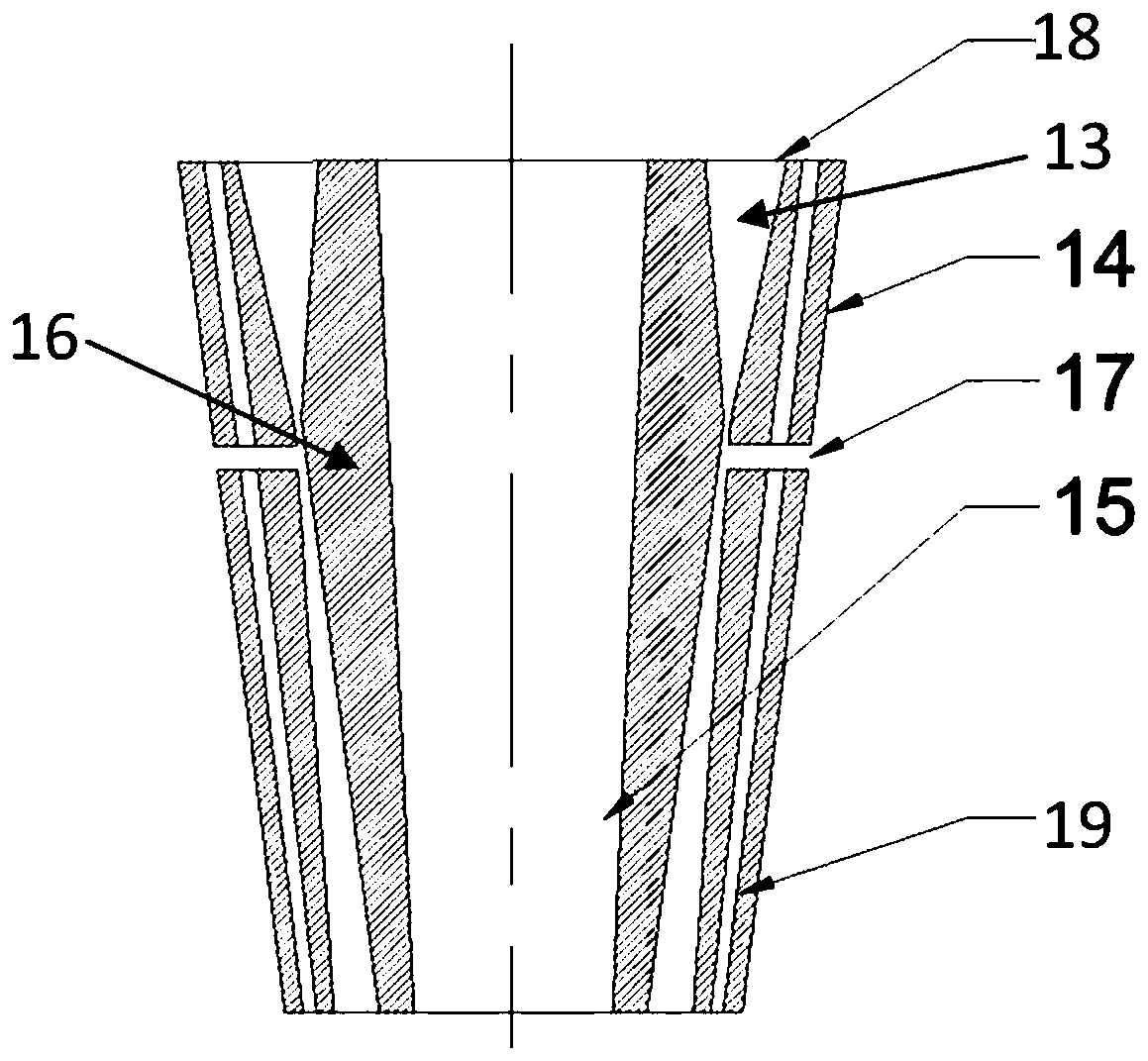

[0048] The technical solutions of the present invention are described in detail below with reference to the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but do not limit the protection scope of the present invention.

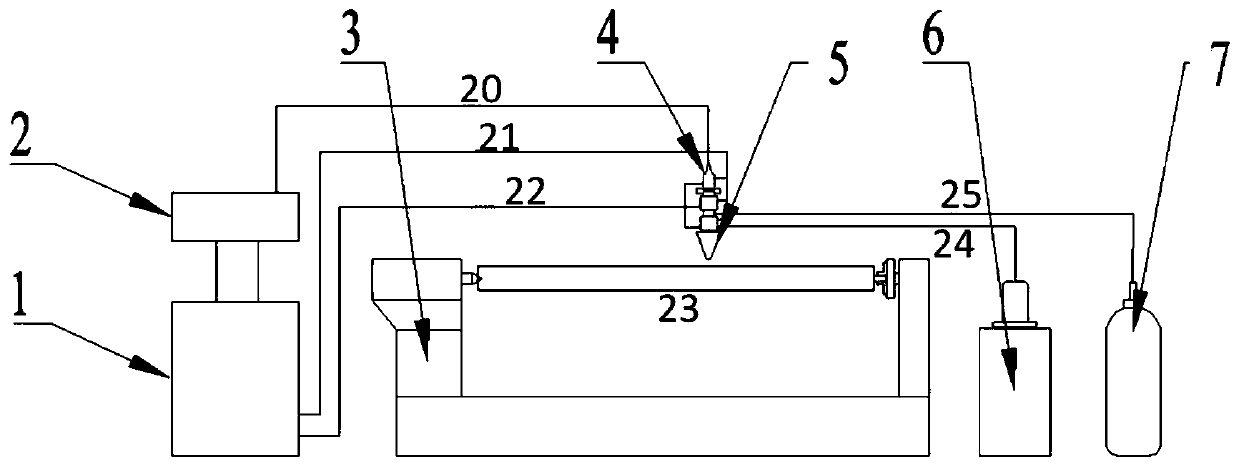

[0049] The present invention proposes a supersonic laser deposition device, such as attached figure 1 As shown, the device includes: a chiller 1, a laser generator 2, a machine bed 3, a laser processing head 4, a laser deposition spray gun 5, a powder feeder 6, a high-pressure air source 7, and transmission optical fibers, water pipes, air pipes and powder Tube.

[0050] The chiller 1 is connected to the laser generator 2 and the laser deposition spray gun 5 through water pipes. Specifically, the chiller 1 is connected to the laser generator 2 through the inlet and outlet water circulation pipes 21 and 22, as the laser generator. At the same time, the chiller 1 is connected to the laser deposition sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com