Stirring device for spray-blowing and stirring integrated molten iron desulphurization

A stirring device and a technology for desulfurization of molten iron, applied in the field of molten iron pretreatment, can solve the problems of low utilization rate of desulfurization agent, short treatment time, large temperature drop of molten iron, etc., improve the dynamic conditions of molten iron, and increase and decrease the cost of equipment investment. Effect of temperature drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

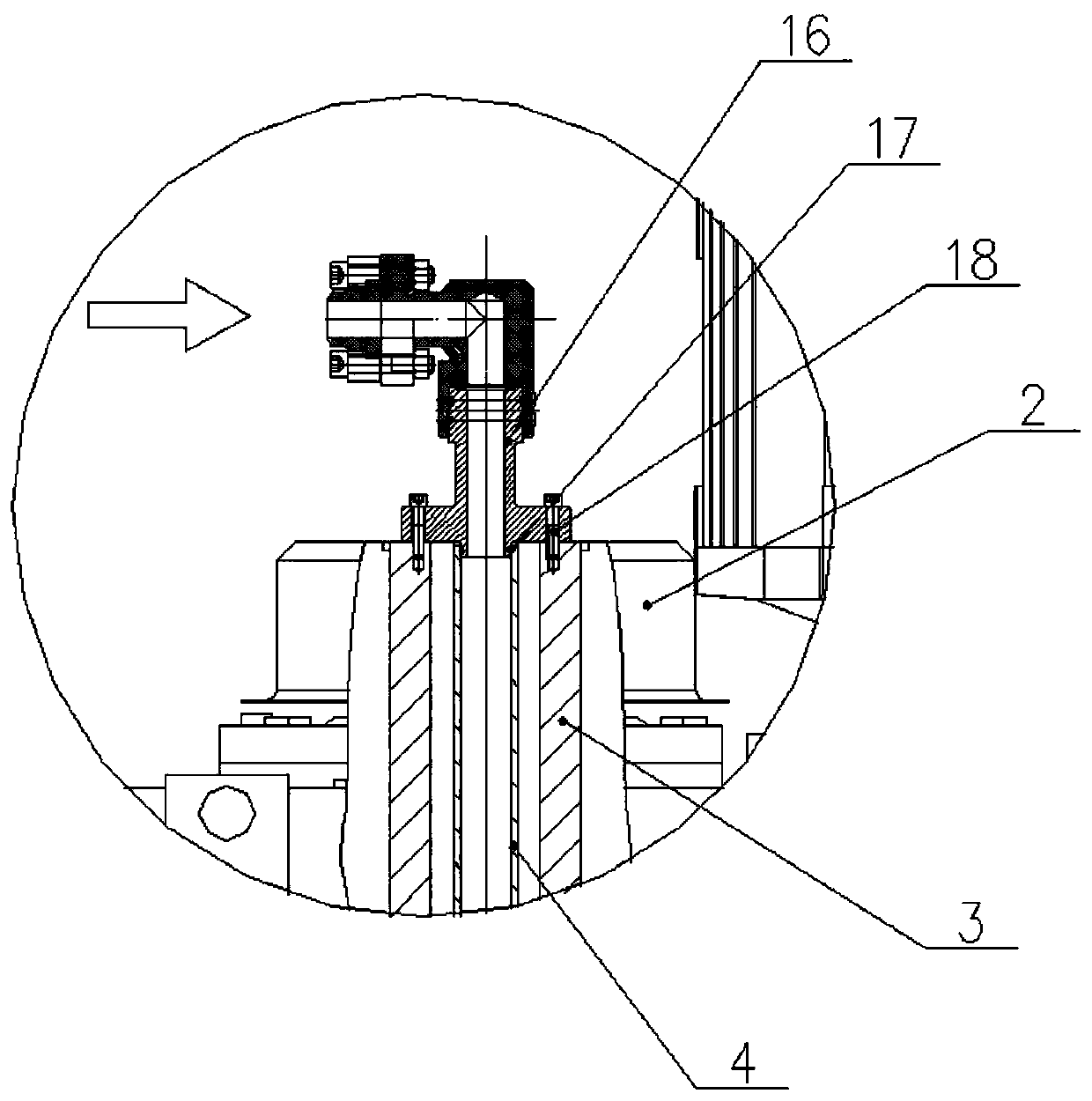

[0022] Such as figure 1 A stirring device for blowing and stirring composite molten iron desulfurization is shown, which includes a lifting frame 1, a rotary drive system, a transmission shaft 3, a stirring head and a powder air pipe. The lifting frame 1 is driven by a lifting drive system and can be vertically Lifting and locking; the rotary drive system is installed on the lifting frame 1, the drive end of the rotary drive system is connected to the transmission shaft 3; the transmission shaft 3 is vertically arranged, and the lower end of the transmission shaft 3 passes through the lower steel platform and is connected to the stirring head The powder gas pipe is located inside the transmission shaft 3 and the stirring head, and is arranged along the axial direction of the two; the inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com