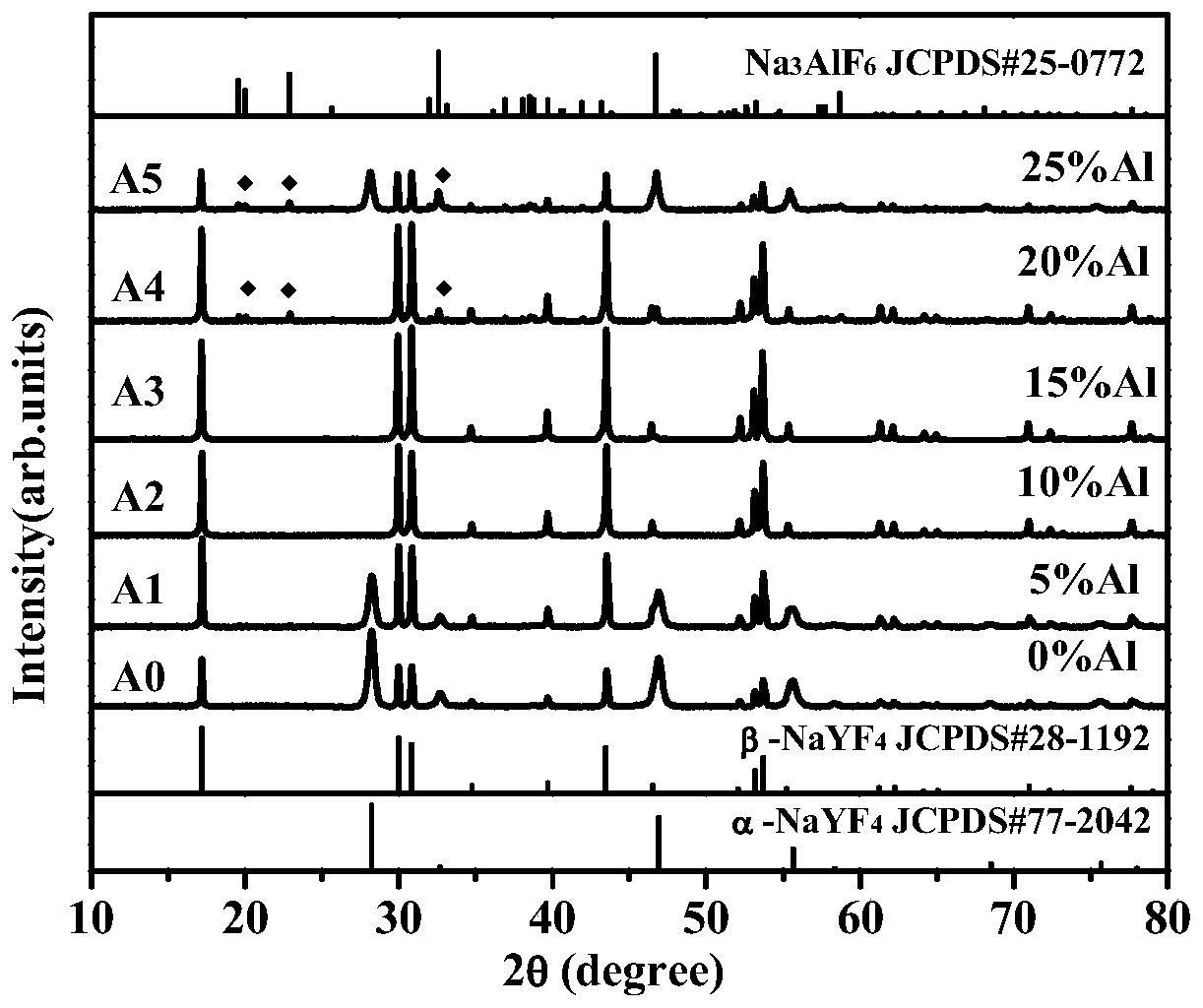

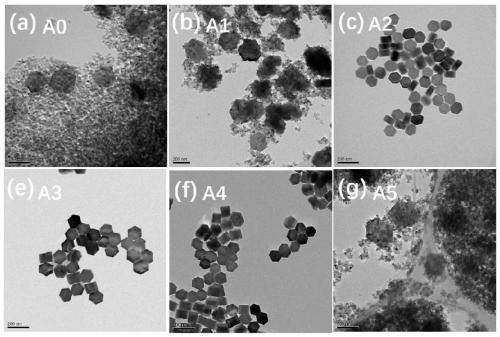

Preparation method of Al<3+> doped hexagonal phase NaYF4:Yb, Er upconversion material

A conversion material and hexagonal phase technology, applied in the field of preparation of hexagonal phase NaYF4:Yb, Er up-conversion materials, can solve the problems of high purity and small size, etc., to achieve increased up-conversion fluorescence intensity, high fluorescence intensity, The effect of important economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a kind of Al 3+ doped hexagonal NaYF 4 : Yb, the preparation method of Er up-conversion material, specifically comprises the following steps:

[0030] 1) According to the molar ratio of 2: 0.78: 0.2: 0.02: 0.05, the trifluoroacetate solution of Na, Y, Yb, Er, Al was added into a three-necked flask and mixed to obtain a mixed solution A;

[0031] 2) Stir and evaporate the mixed solution A to dryness at 80°C to remove moisture, then continue to add a mixed solvent consisting of 3mL oleic acid and 9mL octadecene to the above-mentioned three-necked flask, stir and vacuumize at 100°C to Dewatering and deoxygenation to obtain reaction solution B;

[0032] 3) Argon gas was slowly introduced into the reaction solution B of the three-necked flask, and then, the temperature was raised to 300° C. at a heating rate of 10° C. / min, and the reaction was kept for 50 minutes to obtain a yellow colloidal solution C;

[0033] 4) Cool the colloidal solution C naturally, then, use absolu...

Embodiment 2

[0035] a kind of Al 3+ doped hexagonal NaYF 4 : Yb, the preparation method of Er up-conversion material, specifically comprises the following steps:

[0036] 1) According to the molar ratio of 2: 0.78: 0.2: 0.02: 0.01, the trifluoroacetate solution of Na, Y, Yb, Er, Al was added into a three-necked flask and mixed to obtain a mixed solution A;

[0037] 2) Stir and evaporate the mixed solution A to dryness at 80°C to remove moisture, then continue to add a mixed solvent consisting of 3mL oleic acid and 9mL octadecene to the above-mentioned three-necked flask, stir and vacuumize at 100°C to Dewatering and deoxygenation to obtain reaction solution B;

[0038] 3) Argon gas was slowly introduced into the reaction solution B of the three-necked flask, and then, the temperature was raised to 300° C. at a heating rate of 10° C. / min, and the reaction was kept for 50 minutes to obtain a yellow colloidal solution C;

[0039] 4) Cool the colloidal solution C naturally, then, use absolu...

Embodiment 3

[0041] a kind of Al 3+ doped hexagonal NaYF 4 : Yb, the preparation method of Er up-conversion material, specifically comprises the following steps:

[0042] 1) According to the molar ratio of 2: 0.78: 0.2: 0.02: 0.15, the trifluoroacetate solution of Na, Y, Yb, Er, Al was added into a three-necked flask and mixed to obtain a mixed solution A;

[0043]2) Stir and evaporate the mixed solution A to dryness at 80°C to remove moisture, then continue to add a mixed solvent consisting of 3mL oleic acid and 9mL octadecene to the above-mentioned three-necked flask, stir and vacuumize at 100°C to Dewatering and deoxygenation to obtain reaction solution B;

[0044] 3) Argon gas was slowly introduced into the reaction solution B of the three-necked flask, and then, the temperature was raised to 300° C. at a heating rate of 10° C. / min, and the reaction was kept for 50 minutes to obtain a yellow colloidal solution C;

[0045] 4) Cool the colloidal solution C naturally, then, use absolut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com