Quasi-earth-surface IV-type water standard deep treatment catalyst system, treatment method and device

A kind of advanced treatment and catalyst technology, applied in physical/chemical process catalysts, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficult to achieve, reduce pollutant concentration, improve effluent indicators, and achieve tailwater depth Purifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

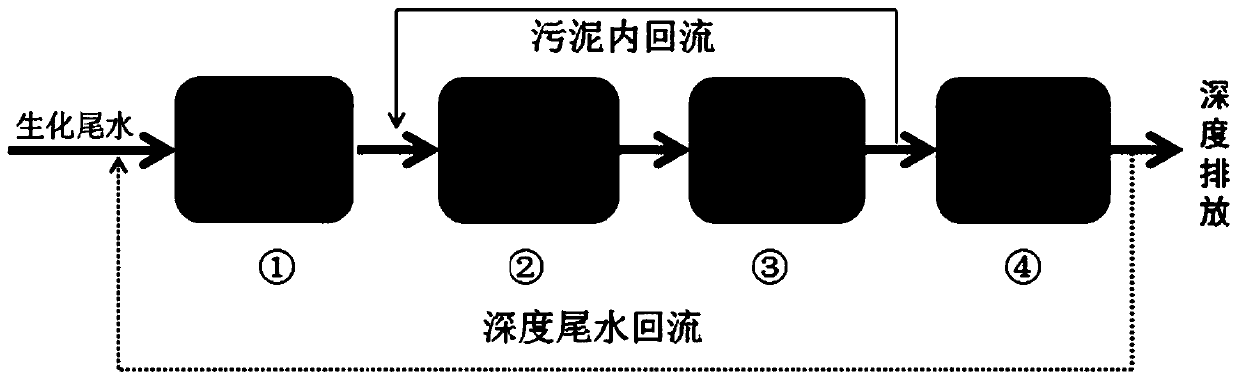

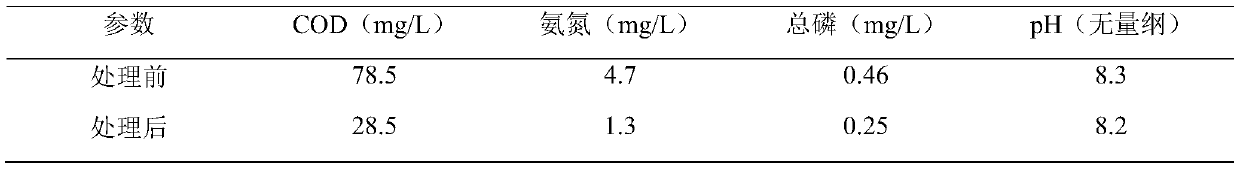

[0062] Such as figure 1 As shown, the biochemical tail water parameter indicators of a chemical centralized sewage treatment plant are as follows, COD is 78.5mg / L, ammonia nitrogen is 4.7mg / L, SS (suspended solids) is 35mg / L, total phosphorus is 0.46mg / L, and pH=8.3. The main residual pollutants detected in the wastewater were nitrobenzene and chlorinated organic compounds.

[0063] In this embodiment, iron shavings are selected for zero-valent iron, copper shavings are selected for zero-valent copper, and columnar activated carbon is selected for activated carbon. The front-end pre-reduction unit is equipped with filler according to the mass ratio of zero-valent iron / zero-valent copper / activated carbon of 70:20:10, the filling rate is 60%, and the reactor volume is set to 5L; the hydraulic retention time is controlled to 10h, and the biochemical deep oxidation unit selects exposure Gas biological filter BAF system, filled with 80% filler, hydraulic retention time is 20h, the...

Embodiment 2

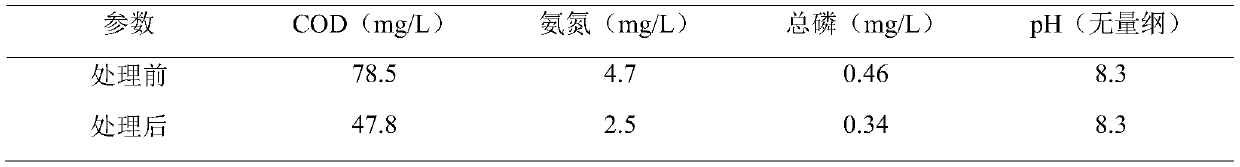

[0078] The biochemical tail water parameters of a chemical centralized sewage treatment plant are as follows, COD is 75.5mg / L, ammonia nitrogen is 4.9mg / L, SS (suspended solids) is 33mg / L, total phosphorus is 0.48mg / L, and pH=7.8. The main remaining pollutants detected in wastewater were sulfonic acid organics and chlorinated organics.

[0079] In this embodiment, iron filings are selected for zero-valent iron, copper filings are selected for zero-valent copper, and spherical activated carbon is selected for activated carbon. The front-end pre-reduction unit is equipped with filler according to the mass ratio of zero-valent iron / zero-valent copper / activated carbon 60:20:20, the filling rate is 65%, the reactor volume is set to 5L, and the hydraulic retention time is controlled to 8h; the biochemical deep oxidation unit selects the membrane Bioreactor MBR system, the hydraulic retention time is 15h, the secondary deep purification unit is equipped with filler according to the m...

Embodiment 3

[0084] The biochemical tail water parameters of a chemical centralized sewage treatment plant are as follows, COD is 67.8mg / L, ammonia nitrogen is 3.9mg / L, SS (suspended solids) is 40mg / L, total phosphorus is 0.42mg / L, pH=8.3. The main residual pollutants detected in the wastewater were ibuprofen intermediates and chlorinated organic compounds.

[0085] In this embodiment, iron slag is selected for zero-valent iron, copper slag is selected for zero-valent copper, and rod-shaped activated carbon is selected for activated carbon. The front-end front-end pre-reduction unit is equipped with filler according to the mass ratio of zero-valent iron / zero-valent copper / activated carbon 60:15:25, the filling rate is 70%, the reactor volume is set to 8L, and the hydraulic retention time is controlled to 10h; biochemical deep oxidation unit selection Aerobic sludge system, the sludge concentration MLSS is 3980mg / L, the hydraulic retention time is 18h, followed by a deep settling tank to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com