Coking residual sludge treatment method

A technology for excess sludge and treatment methods, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., and can solve the problem of low efficiency and dehydration workload of coking excess sludge Large and other problems, to achieve the effect of cost reduction, stable and controllable quality, and stable coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

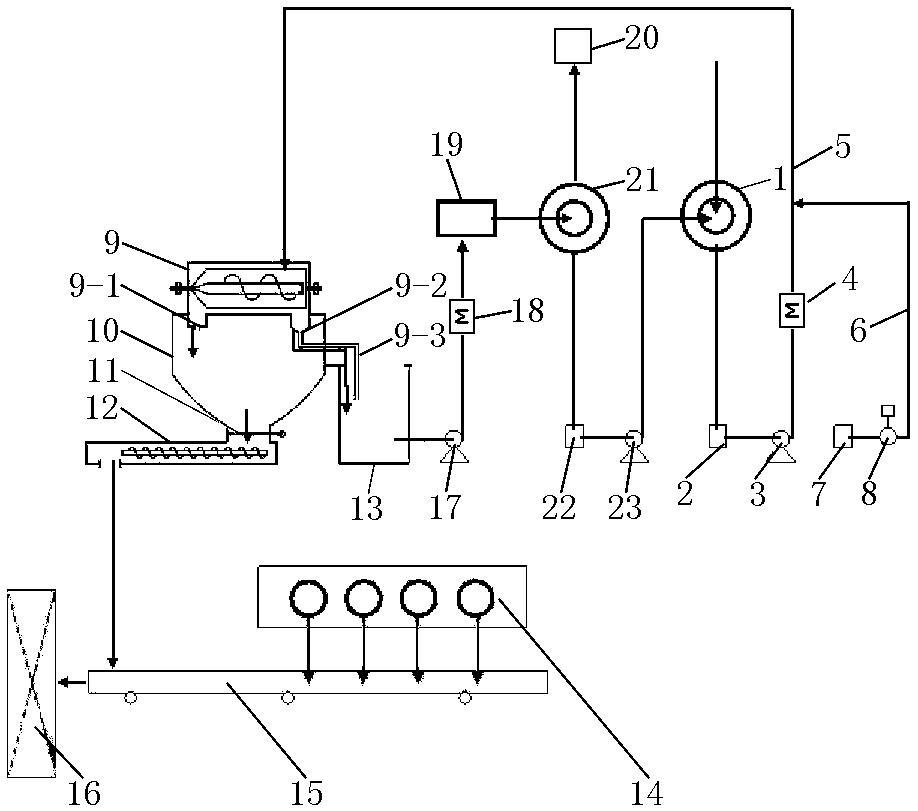

[0023] figure 1 The coking residual sludge treatment system shown includes a mixed sludge tank 1, a mixed sludge well 2, a mixed sludge pump 3, a sludge flow meter 4, a water treatment solution tank 7, a metering pump 8, and a sludge dehydrator 9 , dewatered sludge buffer tank 10, flashboard 11, screw batcher 12, separated sewage tank 13, wherein, the mixed sludge well 2 is connected to the bottom of the mixed sludge pool 1, and the mixed sludge well 2 is connected with the mixed sludge pump 3 The sludge dewatering machine 9 is connected, and the sludge metering pump 4 is installed on the conveying pipe 5 connecting the mixed sludge pump 3 and the feed port of the sludge dewatering machine 9, and the rear pipeline of the sludge metering pump 4 is connected with a chemical conveying pipe 6. The medicine delivery pipe 6 is connected with the water treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com