Software slicing method based on colored photocuring 3D printer

A 3D printer and colored light technology, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problems of lack of color slicing software and inability to print color products, etc., and achieve the development of light-curing 3D printing technology , The effect of photocuring 3D printing technology improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

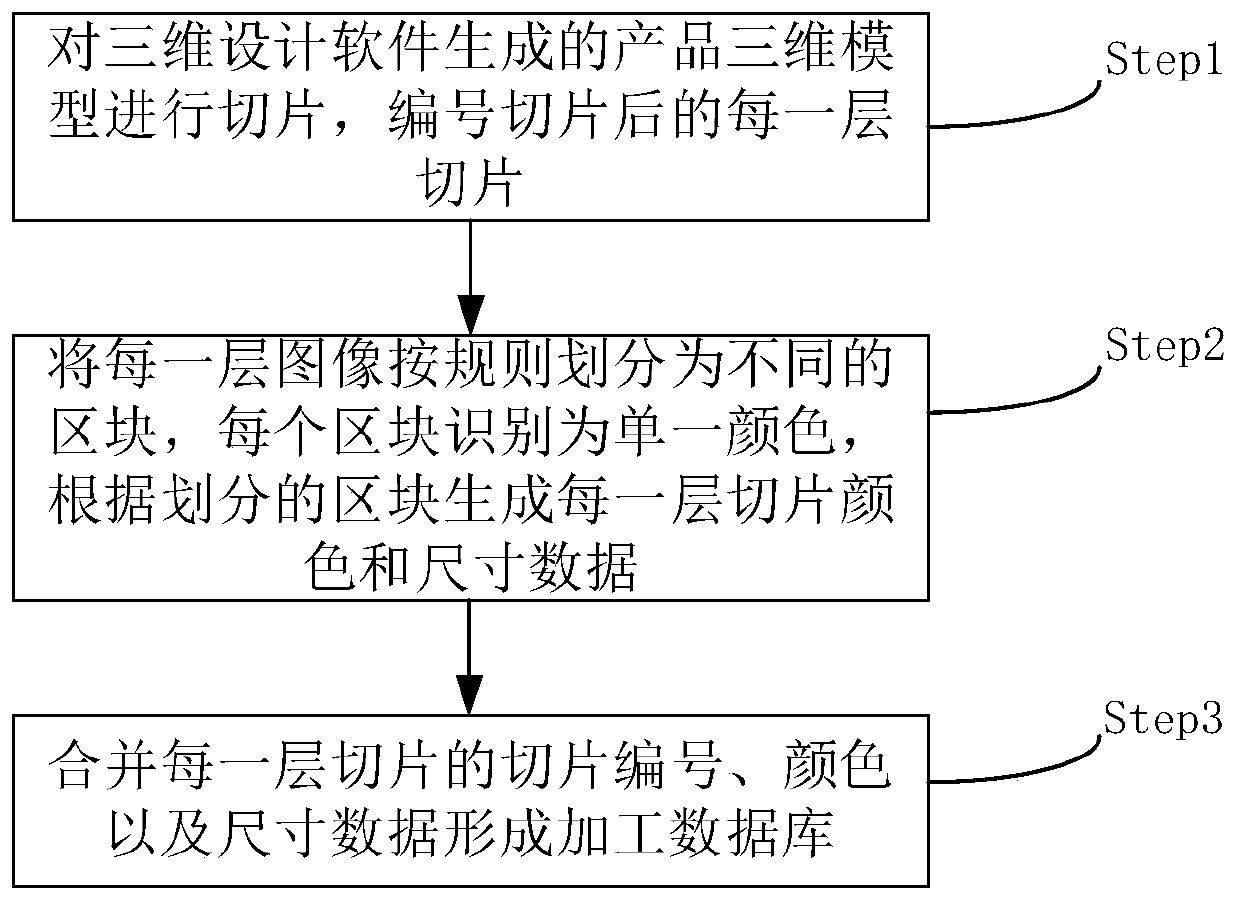

Method used

Image

Examples

Embodiment 1

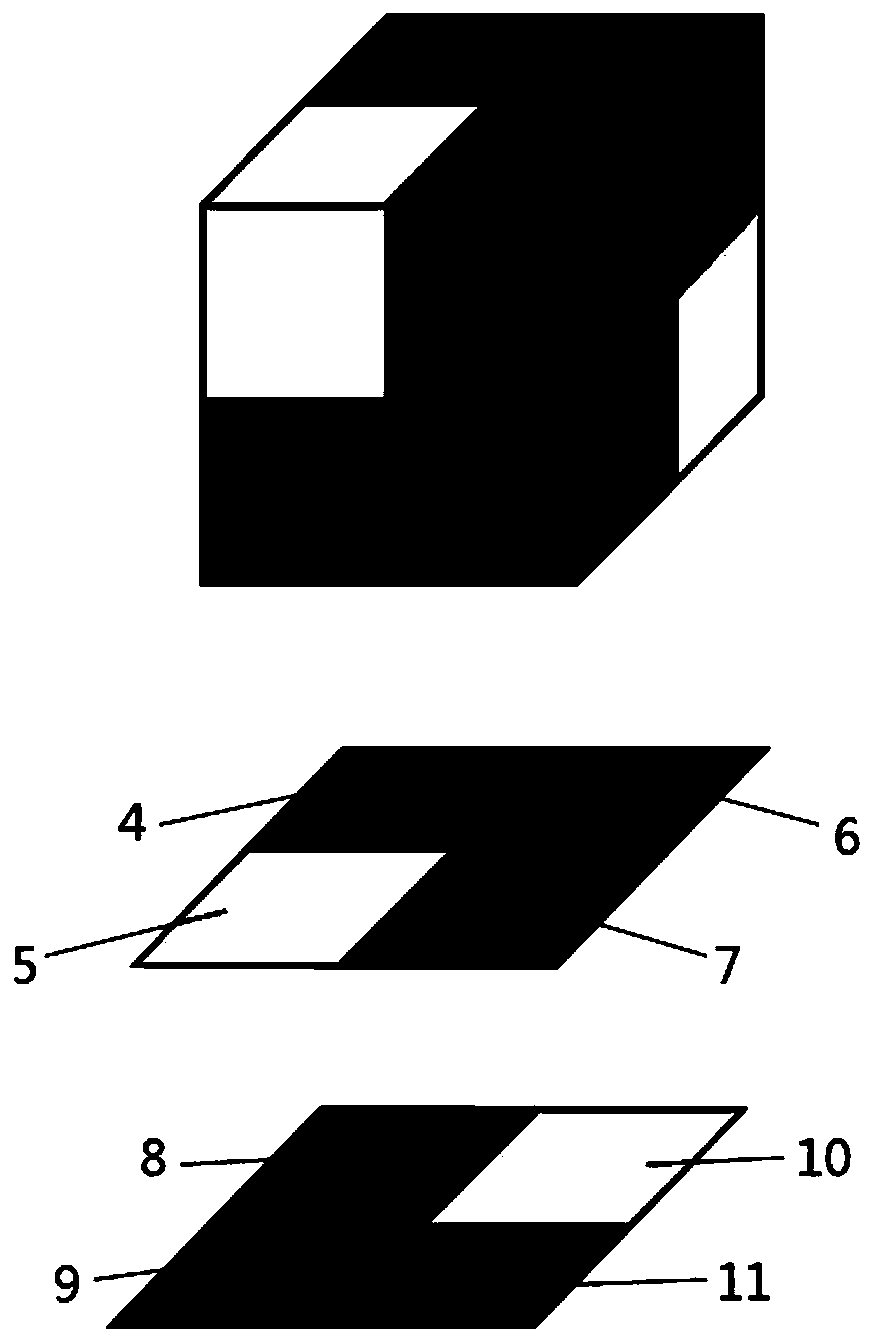

[0030] Assuming a product, among the first three slices, the first slice needs to be divided into 5 blocks, and the colors of the 5 blocks are red, green, yellow, black and white; the second slice needs to be divided into 3 blocks, 3 The colors of the first blocks are red, yellow, and white in turn; the third layer needs to be divided into 4 blocks, and the colors of the 4 blocks are black, white, red, and green in turn.

[0031] According to the above slicing method, the block data of the five blocks of the first layer in the processing database are: 151R, 152G, 153Y, 154B and 155W; the data of the three blocks of the second layer are: 231R, 232Y and 233W; the data of the four blocks of the third layer are: 341B, 342W, 343R and 344G.

[0032] By analogy, the block data of all slices are generated and transmitted to the color photocuring 3D printer.

[0033] Load the trough of the color included in the slice into the color light-curing 3D printer, and print layer by block one...

Embodiment 2

[0035] Assuming a product, in the first three slices, the first slice needs to be divided into one block, and the color of one block is red; the second layer needs to be divided into one block, and the color of one block is yellow in turn; The third layer needs to be divided into 1 block, and the color of each block is black in turn.

[0036] According to the above slicing method, the data of one block of the first layer is 111R in the processing database; the data of one block of the second layer is 211Y; the data of one block of the third layer is 311B.

[0037] By analogy, the block data of all slices are generated and transmitted to the color photocuring 3D printer.

[0038] Load the trough of the color included in the slice into the color light-curing 3D printer, and print layer by block one by one. When the printing of one layer is completed, the forming platform moves a height of the slice to print the next layer of slices. until all slices are printed.

[0039] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com