Ferro-manganese humic acid modified biochar, preparation method thereof and application of biochar

A biochar and humic acid technology, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve environmental hazards, unsuitable for arsenic-contaminated soil treatment, and unsuitable for cadmium-contaminated soil treatment, etc., to achieve Good practical prospect, simple and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

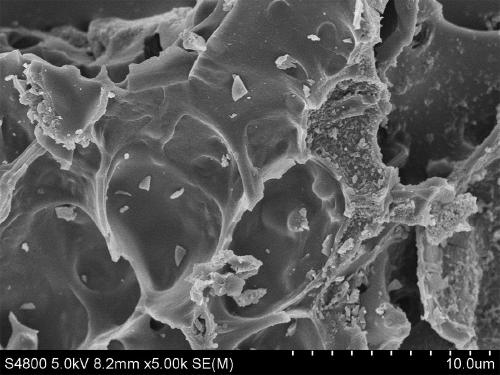

Image

Examples

Embodiment 1

[0038] Rice husk was selected as the biomass raw material, and the rice husk was air-dried and crushed. Each 1g of crushed rice husk was soaked in 10mL of 2% potassium permanganate solution for 24 hours. The pyrolyzed product was passed through a 100-mesh sieve to obtain biochar loaded with manganese oxides, and a concentration of 5 g / L Fe was added dropwise to 1 g of biochar loaded with manganese oxides. 2+ Solution 20mL, after stirring for 15min, add 34mL alkaline sodium humate solution (the alkaline sodium humate preparation method: 1g sodium humate is dissolved in 0.1mol / L sodium hydroxide solution, and then use 0.45 micron Membrane filtration solution), stirring for 1 hour, aging the mixed solution at 70°C for 12 hours, separating the solid from the liquid, drying the solid, and passing through a 100-mesh sieve to obtain the ferromanganese humate modified biochar.

Embodiment 2

[0040] Straw was selected as the biomass raw material, and the straw was air-dried and crushed. Each 1 g of the crushed straw was soaked in 6 mL of 2% potassium permanganate solution for 24 hours. After filtration, it was pyrolyzed at 400 °C for 3 hours without oxygen. The pyrolyzed product was passed through a 100-mesh sieve to obtain biochar loaded with manganese oxides, and a concentration of 5 g / L Fe was added dropwise to 1 g of biochar loaded with manganese oxides. 2+ Solution 15mL, after stirring for 15min, add 30mL alkaline sodium humate solution (the alkaline sodium humate preparation method: 1g sodium humate is dissolved in 0.1mol / L sodium hydroxide solution, and then use 0.45 micron Membrane filtration solution), stirring for 1 hour, aging the mixed solution at 70°C for 10 hours, separating the solid from the liquid, drying the solid, and passing through a 100-mesh sieve to obtain the ferromanganese humate modified biochar.

Embodiment 3

[0042] Animal feces were selected as the biomass raw material, and the animal feces were air-dried and pulverized. Each 1g of pulverized animal feces was soaked in 15mL of 2% potassium permanganate solution for 24 hours. After filtering, it was pyrolyzed at 900°C for 4 hours without oxygen. The pyrolyzed product was passed through a 100-mesh sieve to obtain biochar loaded with manganese oxides, and a concentration of 5 g / L Fe was added dropwise to 1 g of biochar loaded with manganese oxides. 2+ Solution 25mL, after stirring for 15min, add 40mL alkaline sodium humate solution (the alkaline sodium humate preparation method: 1g sodium humate is dissolved in 0.1mol / L sodium hydroxide solution, and then use 0.45 micron Membrane filtration solution), stirring for 1 hour, aging the mixed solution at 70° C. for 14 hours, separating the solid from the liquid, drying the solid, and passing through a 100-mesh sieve to obtain the ferromanganese humic acid modified biochar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com