Apparatus and method for producing 3-acetyl-1-propanol by continuous hydrogenation of 2-methylfuran

A technology of acetyl n-propanol and methyl furan, which is applied in the chemical industry, can solve the problems of wasting hydrogen, cumbersome intermediate material transfer links, and low industrialization efficiency, and achieve the effects of reducing hydrogen loss, improving efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

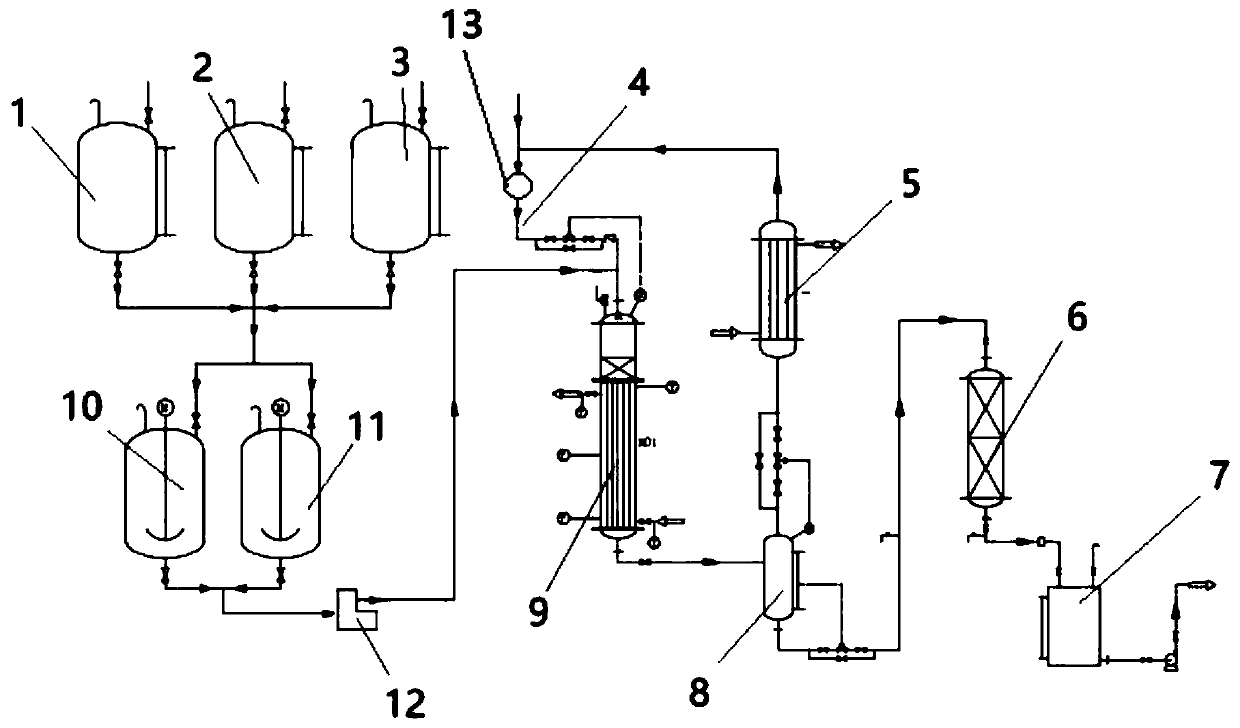

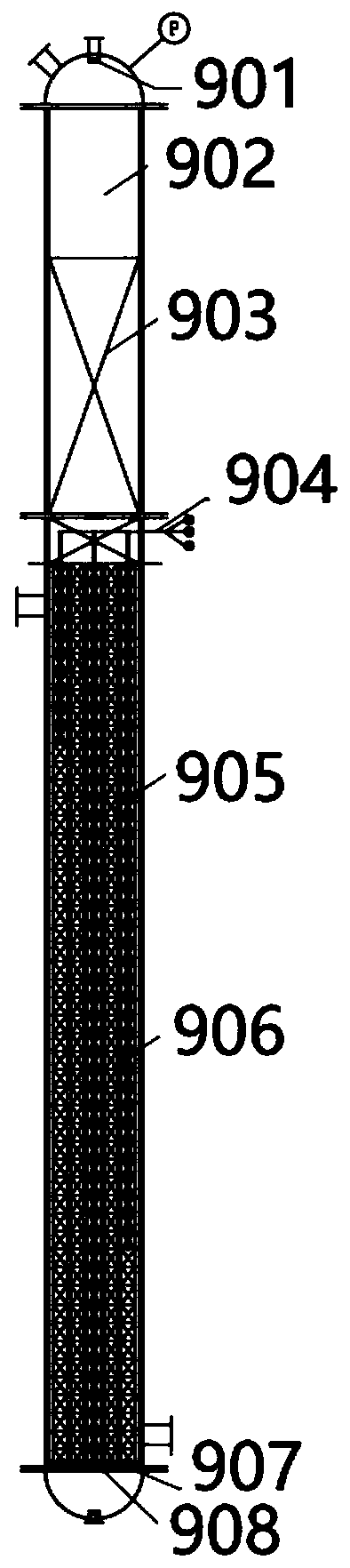

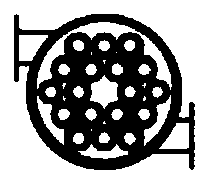

Method used

Image

Examples

Embodiment

[0046] Replace the fixed bed reactor and related pipelines with nitrogen and hydrogen for three times respectively, control the reaction temperature of the reactor at 25-30°C, start to flow hydrogen into the reactor, keep the pressure of hydrogen at 0.30MPa, and pass the metering pump at 280kg / h The mixture of 2-methylfuran, solvent and water (the ratio of the three is 4:2:1) is fed from the mixing kettle. After the feed pump is turned on, the discharge valve is opened, and the reaction liquid is pressed through the filter in the kettle. After the filtrate in the gas-liquid separator reaches a certain level, the bottom valve is automatically opened, and the reaction liquid enters the secondary reactor for neutralization, and the neutralized liquid is collected in the receiving tank for subsequent distillation, etc. Operation to obtain a qualified product with a yield of 85.3%. A small amount of unreacted 2-methylfuran, solvent and by-product 2-methyltetrahydrofuran distilled ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com