Novel application of sulfonic acid group aromatic compounds

A technology of aromatic compounds and compounds, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of palladium ion non-adhesion, poor adhesion, insufficient surface charge capacity of substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0062] According to the ingredients and their concentrations described in Table 1, pre-dip solutions were prepared. The preparation method is as follows:

[0063] Set the total volume to 2L, calculate the mass of each component, then weigh each component, and dissolve them in a certain amount of water, mix and stir evenly, and then set the volume to 2L for later use.

[0064] Table 1

[0065]

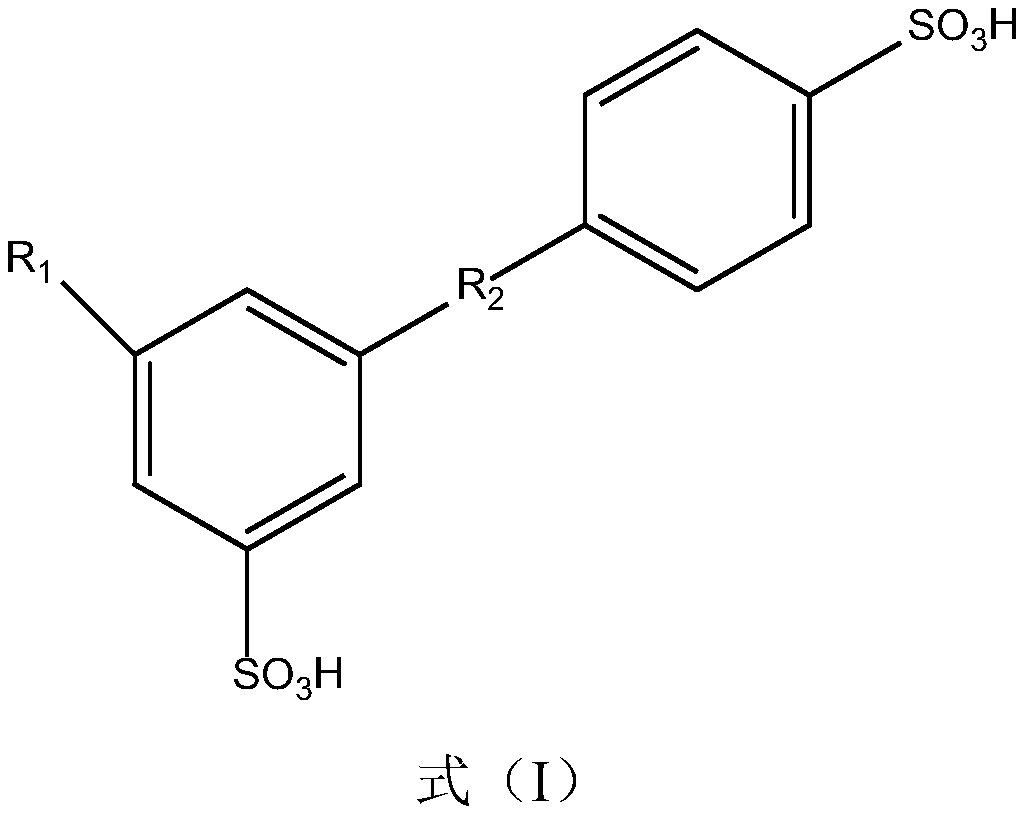

[0066] Among them, the structure of methyl methylene is

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com