High-strength photonic crystal hydrogel, preparation method and application thereof

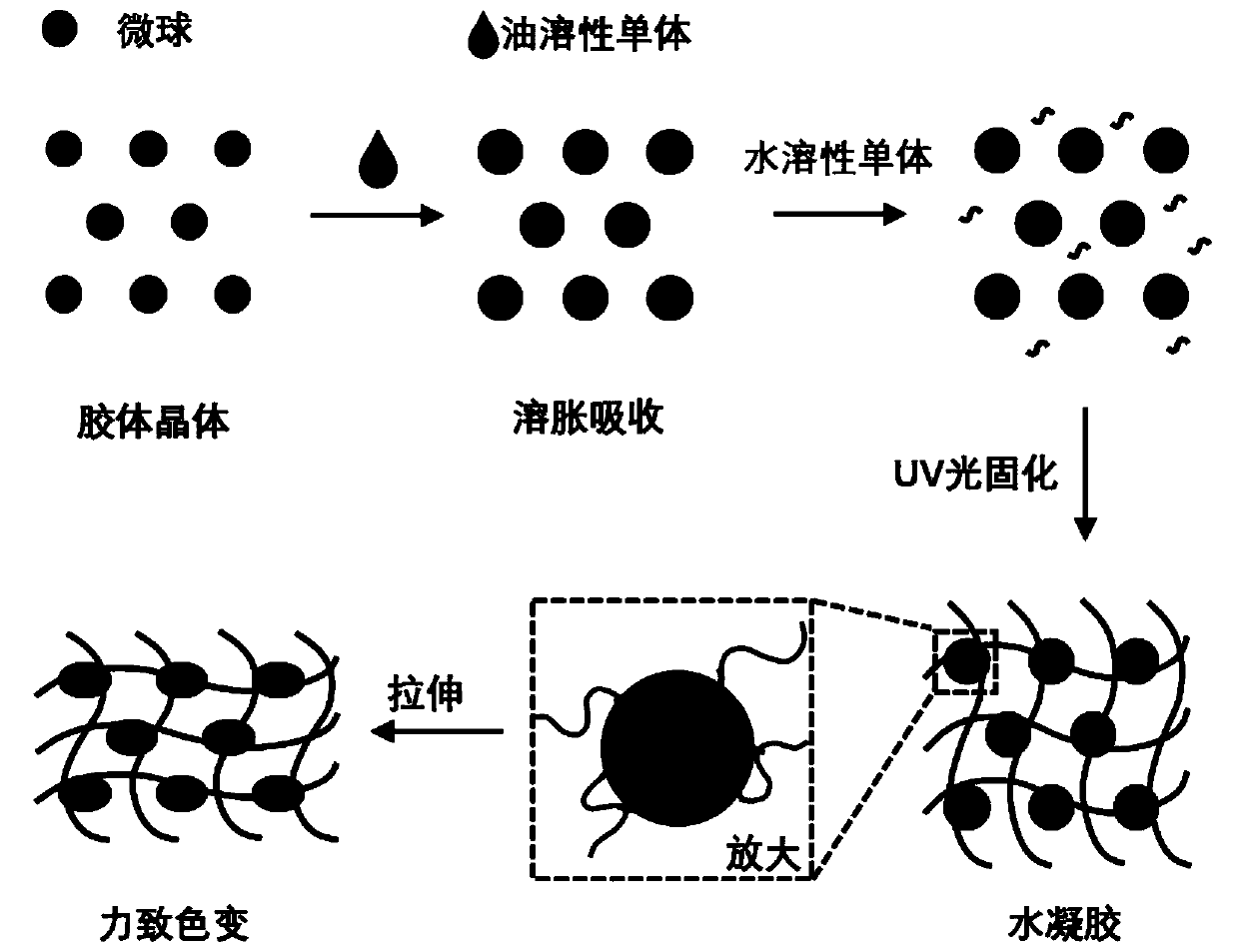

A photonic crystal and hydrogel technology, which is applied in the field of high-strength photonic crystal hydrogel and its preparation, can solve the problems of weak interface strengthening force and insufficient mechanical properties of photonic crystal hydrogel, and achieve good mechanical properties and excellent The effect of high optical characteristics and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of high-strength photonic crystal hydrogel, comprising the steps of:

[0048] S1. Weigh 0.015 parts of sodium lauryl sulfate and add it to 85 parts of water and stir to dissolve it. After heating to 60°C, add 10 parts of butyl acrylate and 0.7 parts of methacrylic acid in sequence, and continue heating and stirring; wait until the system is heated to 80°C 1.15 parts of ammonium persulfate aqueous solution with a mass concentration of 13% was slowly added dropwise to the system, and kept at 80°C for uniform stirring and reaction for 12 hours to obtain a polymer colloidal crystal emulsion;

[0049] S2. Add 0.025 parts of sodium lauryl sulfate to the mixed solution of 8.8 parts of the emulsion prepared in step S1 and 1.2 parts of absolute ethanol and stir to dissolve. After heating to 40°C, add 0.7 parts of isooctyl acrylate and keep stirring evenly at 40°C 12 hours; then the obtained solution was dialyzed in deionized water for 3 days to remove organi...

Embodiment 2

[0052] A preparation method of high-strength photonic crystal hydrogel, comprising the steps of:

[0053] S1. Weigh 0.013 parts of sodium lauryl sulfate and add it to 85 parts of water and stir to dissolve it. After heating to 60°C, add 10 parts of butyl acrylate and 0.7 parts of methacrylic acid in turn, and continue heating and stirring; when the system is heated to 80°C 1.15 parts of ammonium persulfate aqueous solution with a mass concentration of 13% was slowly added dropwise to the system, and kept at 80°C for uniform stirring and reaction for 12 hours to obtain a polymer colloidal crystal emulsion;

[0054] S2. Add 0.03 parts of sodium lauryl sulfate to the mixed solution of 8.8 parts of the emulsion prepared in step S1 and 1.2 parts of absolute ethanol, stir and dissolve, add 0.7 parts of isooctyl acrylate after heating to 40°C, and keep stirring evenly at 40°C 12 hours; then the obtained solution was dialyzed in deionized water for 3 days to remove organic solvents an...

Embodiment 3

[0057] A preparation method of high-strength photonic crystal hydrogel, comprising the steps of:

[0058] S1. Weigh 0.015 parts of sodium lauryl sulfate and add it to 85 parts of water and stir to dissolve it. After heating to 60°C, add 10 parts of butyl acrylate and 0.5 parts of methacrylic acid in turn, and continue heating and stirring; when the system is heated to 80°C 1.15 parts of ammonium persulfate aqueous solution with a mass concentration of 13% was slowly added dropwise to the system, and kept at 80°C for uniform stirring and reaction for 12 hours to obtain a polymer colloidal crystal emulsion;

[0059] S2. Add 0.03 parts of sodium lauryl sulfate to the mixed solution of 8.8 parts of the emulsion prepared in step S1 and 1.2 parts of absolute ethanol, stir and dissolve, add 0.7 parts of isooctyl acrylate after heating to 40°C, and keep stirring evenly at 40°C 12 hours; then the obtained solution was dialyzed in deionized water for 3 days to remove organic solvents an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com