A kind of triaxial magnetic sensor and preparation method thereof

A sensor and three-axis magnetic technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, instruments, measuring magnetic variables, etc., can solve the problems of complex process, low yield rate, high cost, etc., and achieve simplified process steps, The effect of improving yield rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of preparation method of traditional triaxial magnetic sensor comprises the following steps:

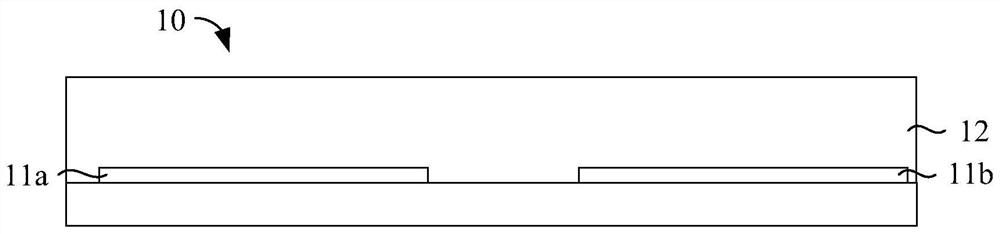

[0044] Such as Figure 1a As shown, step S11 is first performed to provide a CMOS device wafer 10, on which a dielectric layer 12 is formed, and the CMOS device wafer 10 includes a first top metal layer 11a and a second top metal layer Layer 11b.

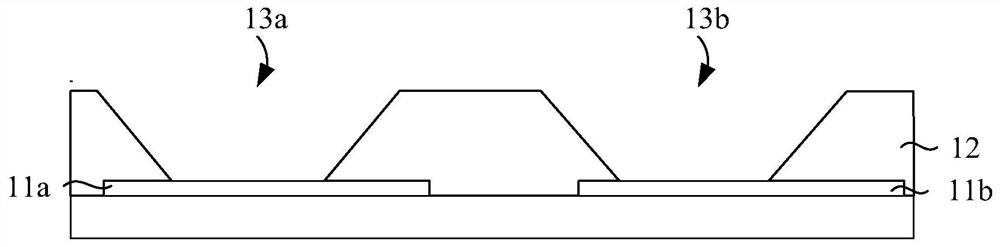

[0045] Such as Figure 1b As shown, step S12 is then performed to form a first groove 13a and a second groove 13b in the dielectric layer 12, the groove bottom of the first groove 13a exposes the first top metal layer 11a, so The bottom of the second groove 13b exposes the second top metal layer 11b.

[0046] Such as Figure 1c As shown, step S13 is then performed to sequentially form the first barrier film layer 20, the magnetic material film layer 30, the protective film layer 40 and the second barrier film layer 50, and the first barrier film layer 20 covers the crystal of the CMOS device. The circle 10, the groove bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com